IBEX 2011 Review

As the International BoatBuilders’ Exhibition & Conference again docks in Louisville, the industry continues a slow and tentative rebound.

IBEX 2011, held Oct. 17-19, marked the boatbuilding expo’s second year in the Kentucky Exposition Center in Louisville. Claiming the largest selection of conference presentations in the show’s 21-year history, IBEX organizers Professional BoatBuilder magazine (Brooklin, Maine) and the National Marine Manufacturers Assn. (Chicago, Ill.) fielded more than 100 industry authorities who conducted 91 different marine industry seminars — up 30 percent from 2010. Exhibitor registration was also up — by 2.3 percent to 556, including 60 new exhibitors and a sold-out Composites Pavilion — and organizers increased the exhibit floor area to 103,900 ft2 (9,650m2). But the official attendance figure, a respectable 4,672, nevertheless represents a 9 percent drop from last year, attributed to the still-lagging economy and the show’s close proximity in time to a Ft. Lauderdale, Fla., boat show. A number of builders elected to keep employees at the plants to prepare boats for the latter. Yet a number of those who could not attend this year said they will definitely be back for IBEX 2012, scheduled for Oct. 2-4 in Louisville.

The mood at the show, however, was a carryover of 2010’s cautious optimism. There was anecdotal evidence of a rebound in small boat production, but large vessel activities still seem restrained by the banking industry’s reticence to approve boat loans in the wake of the mortgage meltdown.

Matt Chambers, president of Marine Concepts/Design Concepts (Cape Coral, Fla.), a marine composites toolmaker and boat fabricator, said that boat companies are now more willing to resume new model introductions, many of which have been on hold since 2008. Marine Concepts, for example, has a backlog of 12 projects and expects that to double by early 2012, despite the recent increases in raw material costs. “Thanks to our capabilities and in-house naval architects/marine designers,” Chambers adds, “we are picking up design, prototyping and tooling functions for companies that have trimmed down and want to resume new models without high overhead.”

On the show floor

Composites One (Arlington Heights, Ill.), Magnum Venus Products (Clearwater, Fla.) and other supplier-members of the Closed Mold Alliance presented several closed mold demonstrations throughout the show, including a Light RTM work cell that produced miniature boat hulls; a vacuum infusion method for building tools that features Optiplus Tooling Resin supplied by CCP Composites (Kansas City, Mo.) and a Vectorply Corporation (Phenix City, Ala.) laminate; and a reusable-bag molding process introduced by Magnum Venus Plastech, called Flex Molding. On the show floor, Composites One showcased CCP’s ArmorFlex 99F gel coats. These advanced technology polyesters are said to have lower volatile organic compounds (VOCs) than standard gel coats and reportedly meet the U.S. Environmental Protection Agency’s (EPA) National Emission Standards for Hazardous Air Pollutants (NESHAP) for Boat Manufacturing. They also are formulated to provide a durable water (osmotic) blister-resistant composite for boat hulls when applied properly and backed with one of CCP’s vinyl ester skin resins or barrier coats. Additionally, POLY-BOND B55LV Displacement Molding Compound — produced by ATC Formulated Polymers Inc. (Burlington, Ontario, Canada) was on display. The polyester-based laminating resin and gap-filling compound was touted as ideal for small-parts production. At one-third the weight of conventional polyester resin, it reportedly enables fast cycle times and achieves a good gel coat surface on both sides of sandwich and single-skin parts using one-step closed molding with low-cost tooling.

Pneumatic sanders with dust capture

Dynabrade Inc. (Clarence, N.Y.) introduced a new series of 2-, 3-, 5- and 7-inch (50.8-, 76.2-, 127- and 177.8-mm) diameter air-powered vacuum sanders featuring a flexible vacuum shroud designed to capture dust, debris and contaminants for a safer, cleaner workplace. The sanders are available in self-generated vacuum and central vacuum models, and the right-angle design of these tools includes a rubber overmold on the housing for smoother operation and transmission of less vibration to the operator.

Long-open-time methacrylates

Engineered Bonding Solutions LLC (Titusville, Fla.) is a new company founded by Matt Brandli and Sam Osae, pioneers in the use of long-open-time, thick-gap-filling structural methacrylate adhesives. Featuring a patent pending chemistry platform that can be modified to provide both 10:1 and 1:1 formulations, the company’s new ACRA LOCK methacrylates can be optimized for either short or long working times, making them adaptable to a wide variety of small to large assembly applications. All the adhesives in the new line are formulated to crossbond with a diverse range of plastics, composites and aluminum or stainless steel, without the need to prime mating surfaces, eliminating the need to buy separate adhesives for each substrate.

Unified adhesive product line

IPS Structural Adhesives (Durham, N.C.) exhibited this year as SCIGRIP Smarter Adhesive Solutions, a new corporate identity intended to unite its North American WELD-ON brand of 10:1 methacrylate adhesives and its HOLDTITE European trade name for 1:1 methacrylate adhesives into one worldwide product family. The company also has upgraded both its U.K. and U.S. plants, installing additional capacity in both facilities to serve the global structural adhesives market.

Restoration education

The International Yacht Restoration School (Newport, R.I.) — known as IYRS (pronounced “Iris”) — highlighted its Composites Technology training program, now in its second year. Providing hands-on training in everything from gel coat spraying to CNC-machining to vacuum infusion and autoclave processing, the nine-month program covers basics but emphasizes today’s latest technologies and prepares graduates for composites careers not only in boatbuilding, but also wind energy and aerospace.

Putties and adhesives

Interplastic Corp. (St. Paul, Minn.) promoted COR-Grip brand polyester and vinyl ester putties and adhesives. Featuring a new name, this broadened product line includes bonding, fillet, fairing and lightweight bedding materials used in boatbuilding or any composites industry where bonding one fiberglass-reinforced plastic (FRP) laminate to another is required. Vinyl ester adhesives are also available and reportedly excel in providing corrosion resistance for applications such as chemical storage tanks.

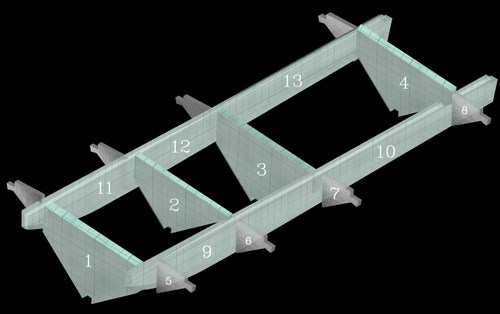

Prelaminated stringer assemblies

Mahogany Company of Mays Landing Inc. (Mays Landing, N.J.) showed off prelaminated stringer grids from balsa- and foam-cored panels produced in-house. The company says that with MicroStation (Bentley Systems Incorporated, Exton, Pa.), Rhino (Rhino3D, Seattle, Wash.) and numerous other software programs it can move directly from a customer’s 3-D CAD file to dual 3-axis CNC cutters; or it can begin by making a pattern, digitizing it with a device such as a Faro LS-880 laser scanner (FARO Technologies, Lake Mary, Fla.), and then flattening 3-D data into a 2-D CAD file. Cut and numbered stringers are shipped as a kit, with an assembly drawing that shows each part’s location and fiberglass tabbing, if desired. Mahogany claims fast turnaround times for any size boat.

Spray tack for reinforcements

NorthStar Chemicals Inc. (Cartersville, Ga.) introduced NauticGrip IF Infusion Molding Adhesive, designed to hold mats, pads and dry reinforcement in place during the infusion process without affecting surface finish or structural integrity. NauticGrip IF will not interfere with the curing process of vinyl esters, polyesters or styrenated resins because it is formulated to become part of the matrix. It is spray applied using self-contained canisters or 15-oz aerosol cans.

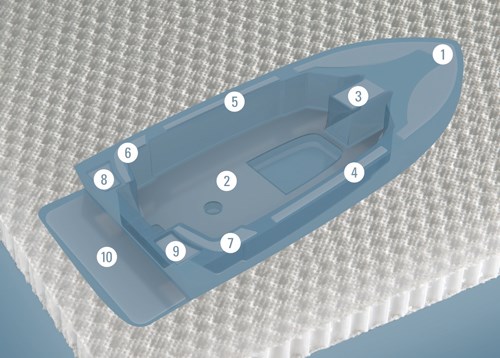

Kitted honeycomb core

Plascore Inc. (Zeeland, Mich.) unveiled its new Kit Cuts CNC-machined plastic honeycomb core kits, numbered and packaged with an easy-to follow placement template. Kits feature net-size shapes with reportedly clean, accurate edges to save boatbuilders and other fabricators time and money. The company uses customer CAD files, which enable kitting engineers to optimize sheet sizes up to 5 ft by 20 ft (1.5m by 6m), minimizing waste and cost. This service is an extension of Plascore’s new focus on aluminum and Nomex honeycomb machining/carving for aircraft applications, such as engine nacelles and interior overhead bins.

Volumized mat for complex shapes

Spheretex GmbH (Ponte Vedra Beach, Fla.) highlighted sphere.core SBC stitch-bonded glass fiber compressed mat, volumized with thermoplastic microspheres, for wet lamination of complex-shaped parts that must have high strength and low weight. Used with epoxy resins, the mat is becoming popular in light truck sidewalls, floors and roofs due to its high impact and water resistance, fast wetout and low weight. Sphere.core SBC IP for vacuum infusion and light RTM features a flow medium in the middle, and it is gaining market share in wind energy applications. Sphere.mat C IP and sphere.ax C IP, also with flow media, are designed to enhance handling and infusion flow. Sphere.mat C IP can combine different weights and thicknesses of chopped strand mat (CSM), enabling very fast part fabrication by building up 800 g/m2 to 2,000 g/m2 (24 oz/yd2 to 60 oz/yd2) of reinforcement in a single 4-mm to 8-mm (0.16-inch to 0.30-inch) layer. Sphere.ax C IP does the same with multiaxials and mat, including ±45° orientations for 800 g/m2 to 1,500 g/m2 (24 oz/yd2 to 45 oz/yd2) in a single ply from 3 mm to 6 mm (0.12 inch to 0.24 inch) thick.

Fire-resistant PET foam

3A Composites, a division of Schweiter Technologies Group (Sins, Switzerland), exhibited its new AIREX T90.60 lightweight, fire-resistant structural polyethylene terephthalate (PET) foam core. Targeted to transportation (marine, rail, bus and aerospace) and architecture applications, the foam combines the fire resistance of the company’s T90 family (which meets NF F16-101, DIN 5510 and FAR 25.853 standards) with high mechanical properties and a low density of 65 kg/m3 (4 lb/ft3). The company also announced the opening of its new manufacturing, conversion and lab facility, to which its Baltek division — formerly housed near New York, N.Y. — was relocated. The reportedly state-of-the-art 115,000 ft2 (10,685m2) facility is in High Point, N.C.

Epoxy infusion resin

Pro-Set Inc. (Bay City, Mich.) promoted its new low-viscosity (250 to 280 cps at 77°F/25°C) epoxy infusion resins that are available with multiple hardener combinations. For example, the company’s M1027 resin could be had with either M2027 or M2028 hardener. Likewise, its M1028 resin system can come with either M2031 or M2033 hardener. Some combinations don’t require postcure and are suitable for bulkheads and stringers. Available now as custom products, these closed-molding epoxy laminating resins are already in use at a number of production boat manufacturers and will soon be PRO-SET standard products. According to the company, they are also exceptionally cost-effective because they are made with raw materials chosen specifically with cost in mind.

Breather/bleeder media

Warm Industrial Nonwovens (Lynnwood, Wash.) was a new exhibitor this year. The company supplies WARM FORM Breather Bleeder cloth, available in sizes up to 124 inches/3m wide for vacuum bag processing. The company describes its plants in Lynnwood and Hendersonville, N.C., as state of the art because of technologies like its thermobonding process. The plants reportedly produce a consistently uniform and stable material that has been well received in the composites industry. A recycling program is offered for volume users, which reuses the virgin fiber in the breather/bleeder in other products.

Two-part epoxy adhesives

West System Inc. (Bay City, Mich.) touted its Six10 thickened, two-part epoxy adhesive in a self-metering cartridge. Dispensed with a standard caulking gun, this system applies a nonsagging adhesive with no metering or filling that cures in temperatures as low as 50°F/10°C and achieves a high-performance bond to wood, metals and composites. Also on display was G/flex marine-grade toughened epoxy that is said to provide excellent adhesion in applications for which traditional epoxies don’t perform well, including hard-to-bond woods (e.g., white oak, teak and mahogany) and wet or damp surfaces.

Welcome new faces

Finally, several of the new exhibitors were composites companies, including Competition Composites (formerly Phil’s Foils based in Ottawa, Ontario, Canada) an established custom and OEM composites fabricator; Piedmont Fiberglass (Taylorsville, N.C.), a 170,000 ft2 (15,800m2) small-parts facility specializing in open molding and Light RTM; and Parson Adhesives (Rochester, Mich.), a producer of two-part structural adhesives for FRP, metal and plastic bonding.

Related Content

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreUpdate: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More