In-mold sensors: In-situ process monitoring for RTM

Technology for monitoring the molding process from within the mold cavity, a practice familiar to injection molders, is making an appearance in resin transfer molding.

Share

Read Next

In the injection molding of plastics, in-mold sensors, as part of a variety of process control packages, have been around for decades. But comparatively recently, similar technology has begun to make an incursion into composites manufacturing in resin transfer molding (RTM), one of a number of closed-molding processes that have eclipsed open molding of composites. One reason is that of all the closed molding models, RTM is most similar in format to injection molding.

The need for sensing technology is driven by customer emphasis on greater part quality and better part-to-part consistency. In response, several suppliers and at least one fabricator are developing and bringing to market new sensor technology specifically targeted at RTM, resin infusion and other types of composites manufacturing processes.

Paul Lagonegro, application manager, Kistler Instrument Corp. (Novi, MI, US), says the processing features particular to RTM are an ideal match for the capabilities of process-control sensors. Fabricators — and their customers — are fond of RTM’s ability to produce lightweight parts with short cycle times and to tight tolerances. Yet RTM usually requires the ancillary manufacture of a preform, which adds steps and requires a greater degree of automation to carry out cost-effectively.

Given Kistler’s experience in manufacturing control sensors for injection molding, Lagonegro says the company’s decision to branch into composites was a natural stepping stone. In view of the growing sophistication of composites manufacturing, the company displayed a prototype sensor for composites processing at the 2012 K Show, and is introducing its first commercial mold-cavity pressure sensor, the 6161 AA, designed for both high- and low-pressure composite processing, this year. The sensor is designed for mold cavity pressures as high as 200 bar, as well as vacuum infusion, and comprises a 4-mm diaphragm welded into a 9-mm cartridge.

The 6161 AA is a direct-contact sensor. The resin acts directly on the front of the diaphragm, which generates a pressure curve via the use of a “charge amp” (transducer/amplifier that gauges the pressure, then converts it to a scalable output value).

Cavity pressure measurement in RTM provides a number of distinct benefits, some similar to the injection molding of thermoplastic, and others unique to both composites processing and composite materials. Like injection molding, the sensors in an RTM mold can be used to monitor and control sequencing of multiple gates, to monitor the flow front and to shut off injection. More distinctively, with respect to RTM, cavity pressure sensors can monitor, as suggested above, mold cavity vacuum pressure as well. This provides, in turn, better control over injection pressure and quality-related issues, such as air inclusions and voids, which could arise from an insufficient or inconsistent vacuum.

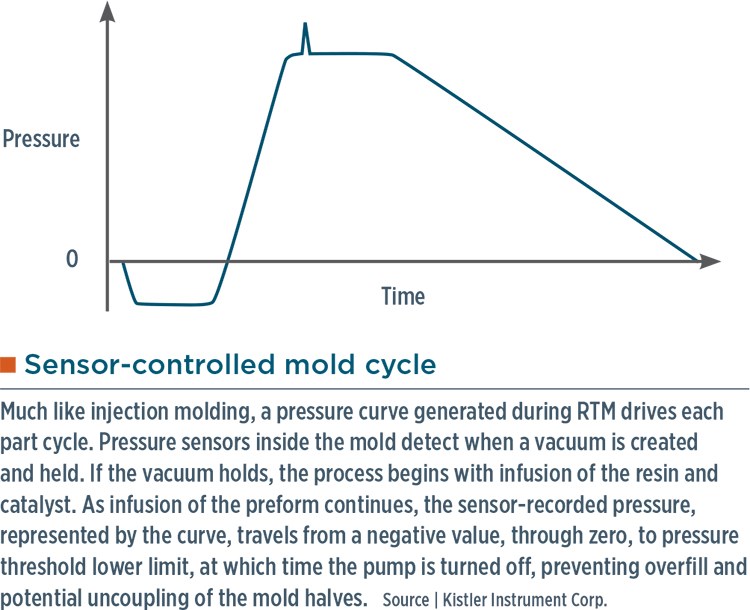

Also, much like injection molding, the pressure curve generated during RTM drives each part cycle and is a key tool that helps the fabricator establish process optimization (see the “Sensor-controlled mold cycle” graph, at top right). During the RTM cycle, pressure sensors inside the mold will detect if a vacuum is created and held. Assuming the vacuum is held, the process begins with infusion of the resin and catalyst. As infusion of the preform continues, the curve travels from a negative value, through zero, to the pressure threshold lower limit, at which time the pump is turned off, preventing overfill and potential uncoupling of the mold halves.

The use of a vacuum to infuse the part is, of course, one of the chief differences between injection molding and a process such as RTM, and this poses a challenge to sensor design. “Traditionally, our sensors have not been exposed to a vacuum,” says Lagonegro, noting that the negative — as opposed to positive —

pressure affects operating conditions and, therefore, posed a different set of sensor design considerations. The 6161 AA, therefore, is designed with an O-ring, which prevents low-viscosity resin from entering the gap in the mounting flange while the cavity is under vacuum. The sensors are calibrated by Kistler before they are shipped to the customer. The calibration data, and a NIST-traceable Calibration Certificate, which is delivered with the sensor, confirms that the sensor performs with a linear output throughout the manufacturing pressure profile and, as a result, those output values will be absolutely reliable as a measure of pressure during the manufacturing process.

Filling the void

As a manufacturer of highly technical, structural composite parts for the automotive racing and aerospace industries, Callaway Carbon (Santa Ana, CA, US) decided to take the matter of process control in composites manufacturing, or lack thereof, into its own hands. Reeves Callaway, founder and owner, says the combination of downward cost pressure and higher quality standards throughout the industry had been pushing the company in the direction of RTM and increasing amounts of automation for a number of years. Having reached the limit of what the company could do without process control technology, it opted to develop its own solution, in house.

Sensors, it turns out, are merely part, albeit a key part, of a holistic process control system developed by the company, one that encompasses hardware and software to close the loop on RTM manufacturing.

“In order to really automate RTM, or any closed molding process, we had to take it one step further than merely installing sensors in molds,” Callaway says. Sensors, he reports, have to work hand-in-hand with software that will replicate all the sequences of part infusion, and monitor and control those sequences throughout each part cycle. “We created software, resulting in a recipe for a part that can control an automated injection system.” In-mold sensors deliver continuous pressure readings to the process control software, which, in turn, monitors and controls resin metering, delivery, infusion and heating/cooling of the mold in a closed-loop configuration for each part cycle, a process the company refers to as the “recipe.” Once the recipe is understood, Callaway notes, it’s simply a matter of replication.

The company has been using sensor-based, automated RTM manufacturing for about five years. Callaway says the sophistication of sensor technology was crucial to successful development of its in-house automation technology: “Fortunately, sensor technology is really good right now at the commercial level.” Just as significant, RTM could be the composites manufacturing method that best lends itself to automation, because it is largely a sequential process. Callaway says the development of process control for it can be broken down into a series of programming problems — for example, how to ensure that step B does not happen until step A has been completed.

Growth of process control systems in composites will require, of course, the participation of those who manufacture molds, and Kistler’s Lagonegro says the company’s early marketing efforts will include toolmakers and fabricators.

Callaway Carbon cuts its own tools so, in addition to owning the process control system, it also controls process setup. Callaway says the number, type and location of the sensors in the mold is part dependent. Almost all the company’s tools are CNC-machined from aluminum. Many, Callaway reports, use two or more piezoresistive pressure sensors, located at the “top” of the tool. He calls the process of determining where to locate the sensors “part science, part art and part luck,” based on years of experience. Prior to production, each tool is run through an auto-calibrate sequence. Process control monitoring will not initiate until sensors are set within predefined limits (the recipe) to permit cycle start. Callaway’s software also allows production to be run in manual mode until the recipe is refined and mature.

One of the more exciting developments in composites is the prospect of system use in the mainstream automotive market, a scenario that is already beginning to play out. Molders with process control technology are likely to have a step up on others in their efforts to meet the auto industry’s stringent, Six Sigma-based quality standards. Lagonegro says that while the composites industry hasn’t been clamoring for process control, “from our perspective, it’s the next big thing.”

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More