Plant tour: Israel Aerospace Industries, Ben Gurion International Airport, Israel

Israel Aerospace Industries (IAI) is developing increasing expertise both in and out of the autoclave as it expands an already broad composites production portfolio.

Israel Aerospace Industries (IAI) was established as Bedek Aviation Co. in 1953, five years after the State of Israel was created. Then situated next to Lod Airport (now known as Ben Gurion International, southeast of Tel Aviv), the company began with 70 employees. As Israel has developed, so has IAI, advancing in technology and operations to its current annual turnover of US$4 billion, an US$11 billion backlog and more than 15,000 employees (6,000 are engineers). It is the largest industrial complex in Israel and a world leader in a range of defense technologies.

Although the company is recognized for its build-to-print (BTP)/build-to-spec (BTS) production capabilities, it is a full defense and aerospace OEM and can design complete aircraft, proceeding through to full flight certification. A case in point, IAI has had full responsibility for the design and analysis, ground and flight testing, manufacturing and assembly of the G150 and G280 business jets for Gulfstream Aerospace Corp. (Savannah, GA, US). IAI achieved joint certification of the G150 business jet with US, European and Israeli aviation authorities.

IAI’s composites operations span parts fabrication and assemblies for business jets and commercial aircraft, unmanned aerial vehicles (UAVs) and military aircraft. Parts produced include vertical and horizontal stabilizers, rudders, wing structures, engine nacelles, floor beams, door surrounds, structural bulkheads, ribs and stiffeners, control surfaces, fairings and radomes. Numbered among its manufacturing capabilities are prepreg hand layup and automated tape layup (ATL), hot drape forming, autoclave and out-of-autoclave cure (OOA) including liquid molding processes, such as resin infusion and resin transfer molding (RTM), plus complex bonding and assembly. The company also designs and builds its own tooling, holds all key aerospace and composites quality certifications and provides quality assurance via comprehensive nondestructive testing and inspection.

IAI promotes itself as a one-stop shop, offering complete design and analysis, engineering, prototyping and production services as well as management of complex supply chains. Its campus spans many acres and numerous buildings, 17 of which house its composites-related manufacture and assembly.

CW’s tour was led by IAI director of marketing and business Eitan Shalit, director of R&D programs Hary Rosenfeld and Dr. Zev Miller, manager of composite materials and processes within IAI’s Engineering & Development Group. The tour was preceded by a company overview in IAI’s new Aero-assemblies Div. composites production building.

Military aircraft and UAV operations

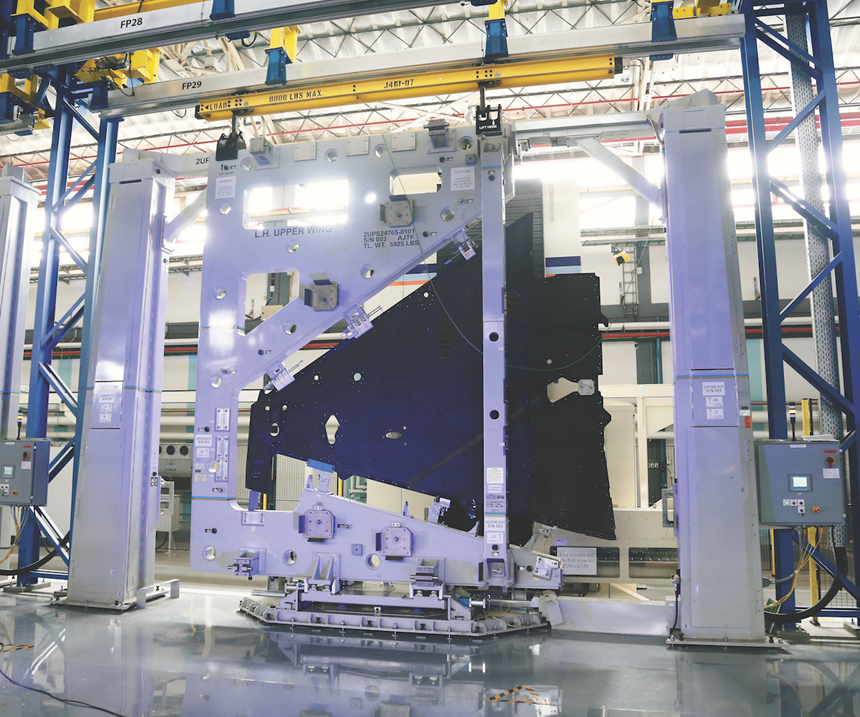

One of IAI’s key composite programs is production of the carbon fiber-reinforced bismaleimide upper and lower skins for the outer wings of the F-35 Lightning II jet. A fully automated assembly line built specifically for this program was inaugurated in 2014 (Fig. 1). IAI celebrated delivery of the 10th shipset of wing structures to Lockheed Martin (Bethesda, MD, US) in July 2016 and is slated to produce more than 800 pairs by 2034.

The company’s relationship with Lockheed Martin began with the F-16 military aircraft. IAI manufactured the vertical stabilizer for several F-16 variants. The skins for this fracture-critical part are built to print, using hand-laid, unidirectional carbon fiber prepreg and autoclave cure.

The company also produced the vertical stabilizer and rudder for the McDonnell Douglas F-15 fighter jet, now supported by Boeing, which uses boron/epoxy composites. For the Sikorsky (Stratford, CT, US) UH-60 Black Hawk helicopter horizontal stabilizer, IAI developed a one-shot carbon fiber reinforced polymer (CFRP) prepreg process for the 2m-long integral composite box. This flight-critical structure achieved a 20% savings in weight and cost vs. the previous metal assembly. IAI took the part from design to first delivery within 9 months in 2003 and has produced 1,500 shipsets to date at its RAMTA division in Be’er Sheva to the south.

IAI has extensive experience in the design and production of UAVs, beginning with its Scout remotely piloted aircraft system (RPAS) in 1978. Scout was followed by the Pioneer, Ranger and Hunter aircraft, all with 100% composite structures, made using wet layup carbon fabric/epoxy skins and honeycomb core. This later transitioned to CF prepreg and Rohacell polymethacrylimide (PMI) foam core from Evonik (Essen, Germany).

Current production includes the Searcher Mk III, the Bird Eye family of aircraft, Panther Fixed Wing and Hovermast 100 vertical takeoff and landing (VTOL) aircraft and the Heron family of unmanned aircraft. The most advanced variant, the Heron TP, measures 14m long with a 26m wingspan. It is a medium-altitude, long-endurance (MALE) UAV, able to fly at an altitude of 13,716m for 40 hours. “All of our UAV aerostructures are 100% composite,” notes Miller.

Commercial aircraft composites

IAI is a Tier 1 supplier for commercial aircraft OEMs and a prime contractor for the Gulfstream G280 business jet. It builds the green aircraft and flies them to the Gulfstream completion center in Dallas, TX, US. In 2009, CW wrote about IAI’s development of an RTM rudder for what is now the G280 (see “RTM showcase: One-Piece Rudder”). IAI had, in fact, designed and built the Galaxy/Astra executive jet, which Gulfstream acquired the rights to in 2001, remarking them as the G100 and G200, respectively. The G280, the latest in this line, accommodates two to 10 passengers. Its outer surface is 35% composite compared to 12% for the G100.

The G280 horizontal stabilizer is an autoclave-cured integral structure. It comprises precured stringers cobonded with adhesive to a CF/epoxy prepreg skin. The vertical stabilizer is a hybrid aluminum and prepreg autoclaved structure while the elevator is a sandwich construction, using CF/epoxy prepreg skins and Nomex honeycomb core. The rudder components are now produced at NCC (North Coast Composites, Cleveland, OH, US) and assembled at IAI’s RAMTA division, in Be’er Sheva. G280 wing-to-body fairings use a CF preform made with plain-weave fabric on one side and noncrimp fabric on the other, with the two plies stitched together. This preform and Rohacell foam core are infused with epoxy resin and cured with vacuum bag only (VBO) in an oven at 180°C.

Equipped for increased production

IAI has six cleanrooms. Five of them (total floor area of 3,010m2) belong to its Aero-assemblies Div., which is the main IAI facility for composite parts manufacturing and assemblies. Although each cleanroom is specialized for its customers’ unique production needs, all are equipped with layup advanced technologies: either with a 16-by-3m contour tape layup (CTL) machine from Fives Cincinnati (Hebron, KY, US), a 15-by-3m automatic tape layup (ATL) machine from MTorres (Navarra, Spain) or, for purposes of manual layup, a laser projection system, supplied by Virtek Vision (Waterloo, ON, Canada).

Elsewhere in the facility:

- IAI has prepreg freezer storage capabilities of 193m2. The company also has invested in Plataine’s (Waltham, MA, US) Total Production Optimization (TPO) software to optimize not only the cutting and nesting of prepreg, but also material usage, reducing waste prepreg and raw material consumption by 5%. In addition, the software has automated production, reducing manual tasks and the associated risk for errors.

- IAI’s production capacity is significant, with 10 autoclaves, seven of which belong to the Aero-assemblies Div. and range in size from 4.5m long and 2m diameter, to the largest at 14m long and 4.7m diameter.

- Prepreg layups are debulked prior to cure using a hot drape forming machine (6.9 by 2.7 by 3.1m) from Electrotherm Industry (Migdal HaEmek, Israel).

- For nondestructive inspection of composite parts, the division has different machines and techniques: four machines with water tank immersion phased-array ultrasonic testing (UT), two through transmission ultrasound (TTU) gantry machines and two 3D robotic systems offering the choice of wide-area phased array TTU with water squirters, phased array pulse echo with skin bubblers (low water flow for coupling to part surface) or air-coupled phased array UT.

The Aero-assemblies Div. also has three CNC machines, ranging to 7 by 3.5m, for composite parts trim and drill and shared CMM equipment for dimensional inspection. The division’s three paint shops and five assembly halls cover a total area of 2,350m2.

Automating RTM

Directly across from the Aero-assemblies Div. composites production facility is the building that houses IAI’s R&D lab for RTM, including an automated preforming cell (see Learn More). “This was originally developed for Bell 525 helicopter seats,” says Rosenfeld, “but we could adapt for other similar platforms.” IAI developed the preforming technology with Techni-Modul Engineering (Coudes, France) to replace hand layup of prepreg. The seat design, developed to meet helicopter crash requirements, uses a combination of reinforcements. Rosenfeld explains, “The seat deforms with the floor during impact and then must withstand maximum acceleration loads.” Glass fiber contributes the necessary flexibility and impact resistance, while carbon fiber provides the strength.

“This helicopter seat was aimed at providing parity with the prepreg baseline, but we can optimize it further for performance and light weight,” says Miller. The cell is set up with an automated material-feed station that supplies reinforcements to an automated cutting machine. A pick-and-place robot from ABB (Zurich, Switzerland) then moves the dry fabric plies onto a preforming tool. Special grippers were developed, which include a sensor to check if the ply is attached. The robot arm also has sensors to check the position of each ply as it is placed using laser projection. A camera validates the orientation and position of the ply vs. standard images recorded in a reference database.

A cast silicone bag provides a reusable vacuum membrane during debulking, which is performed six times. Next, the compacted preform is transferred to a tool where ultrasonic trimming is performed. There is no trimming after the part is molded. Finally, the trimmed preform is placed into a set of matched steel RTM molds.

The resin used is the one-component Prism EP-2400 toughened epoxy from Solvay (Brussels, Belgium). It is degassed first and then injected using a unit supplied by Isojet Equipments (Corbas, France). “Usually you spend a lot of time cleaning the lines and molds, but we have kept the injection setup very simple so that we have a minimal amount to clean,” says Rosenfeld. The resin is heated to 80°C to reduce viscosity for enhanced flow and fiber wetout during injection. “This is fully automated and synchronized with the press,” Rosenfeld notes. The mold, preheated to 120°C, is then closed, vacuum is applied and the resin is injected. Only vacuum is used to flow the resin through the preform. Both temperature and pressure are increased in the mold, reaching 180°C and a pressure of 6 bar during a 2-hour molding cycle.” The mold is cooled to 50°C, opened and the finished part is removed.

Advancing future composites

An adjoining room in the RTM lab houses testing equipment, including two-component injection machines to test new RTM resins: R&D is a significant focus for IAI. It has experience in more than 86 EU-funded multi-partner collaborations, including the following:

- The TANGO project, which demonstrated composite fuselage, wing and center wing box structures. As part of TANGO, IAI designed and manufactured three large CFRP wing ribs, up to 1.7m in length, featuring integral sine-wave stiffener and flanges molded in one shot, using noncrimp fabric and RTM.

- CONDICOMP, organized to develop material state management during composite curing processes.

- ALCAS, which aimed to reduce composite aircraft component manufacturing costs.

- IFATS, established to increase aircraft autonomy.

Three other programs deserve special notice. Within the 8-year MAAXIMUS project, led by Airbus to improve composite airframes, IAI was tasked with studying structural details — including ply drops and stringer runouts (terminations typical at production breaks, such as the main fuselage circumferential joints) — and investigating options to improve strength and weight. For each detail, IAI performed strength predictions, using computer-aided design and engineering (CAD/CAE) and FEM analysis, designed and manufactured relevant test specimens and then compared test results to analyses. Final results were used in the overall program to aid recommendations for future aircraft design and production.

In LOCOMACHS, IAI was one of 31 companies focused on significantly reducing or eliminating the most time-consuming and, thus, expensive but non-value-added operations in composite airframe assembly, such as temporary assembly to check gaps, shimming, dismantling and tool handling. IAI worked with project coordinator SAAB Aeronautics (Linköping, Sweden) and partners GKN Aerospace (Redditch, UK), Turkish Aerospace Industries (Ankara) and the Netherlands Aerospace Centre (NLR, Amsterdam) to build the Lean Assembled Wing Box (LAWiB) (see Learn More) and More Integrated Wing Box (MIWiB) demonstrators. It produced CF/epoxy stringers using noncrimp fabric (NCF) supplied by SAERTEX (Saerbeck, Germany). These stringers were co-bonded to the NCF skin. The resulting parts eliminated shimming on the upper skin-spar interface and reduced fastener count for a 30% cut in assembly labor cost. Miller sees potential use for these concepts on other structures, including smaller wings and tails.

Currently, IAI is taking the lead in two composites-intensive Clean Sky 2 projects: OPTICOMS (Optimized Composite Structures for Small Aircraft) and ECOTECH eco-friendly innovative airframe. As coordinator, IAI is working with the OPTICOMS team, which includes Piaggio Aircraft (Genoa, Italy), Coriolis Composites (Quéven, France), DANOBAT (Elgoibar, Spain) and TechniModul Engineering — to demonstrate automation in low-volume composite structures to reduce cost. The 7m long Piaggio Aircraft wing demonstrator features an integral spar/skin construction produced in one shot. Various technologies are being assessed to determine the most cost-effective manufacturing process. One novel method is Final Pressure Transfer Molding (FPTM). Developed by TechniModul Engineering, IAI’s partner for its automated RTM cell, the FPTM process injects air or gas into a closed cavity to apply up to 10 bar of pressure while curing thermoset prepreg in heated matched molds. The resulting OOA parts are reportedly on par with autoclave-cured prepreg but without requiring the injection of additional resin, as in the Same Qualified Resin Transfer Molding (SQRTM) process (see “SQRTM enables net-shape parts”).

For ECOTECH, IAI together with Invent (Braunshweig, Germany) leads a 12-member consortium tasked with developing new materials, processes and recycling technologies to reduce aircraft production’s environmental footprint. As part of the previous Eco-Design project, IAI helped to select and develop technologies for reducing weight, cost, energy consumption, emissions, hazardous materials and waste, which were validated on three demonstrators in 2017, achieving a 10-20% weight reduction and potential reduction in global warming by more than 50% compared to current practice. In the final stage of ECOTECH, further development in novel materials and process technologies will be validated in the manufacture of four demonstrators — thermoplastics, thermoset, metallic and biomaterial. These demonstrators, plus those from OPTICOMS, will be integrated in the Clean Sky 2 Airframe Integrated Technology Demonstrator (ITD), led by Dassault Aviation (Biarritz, France), Airbus DS (Madrid, Spain) and SAAB (see “Thermoplastic composite demonstrators — EU roadmap for future airframes”).

The company is also exploring additive manufacturing, structural health monitoring and morphing wings, as well as establishing its position in electric propulsion — what it sees as the next era of aviation.

All of this bodes well for IAI’s future. “We have a unique combination of decades-long production experience, capability to develop and implement advanced composites technology and a longtime relationship with both the US and European aerospace industries,” says Shalit. “The commercial and military aerospace markets are increasingly competitive, and composites are a key competence. IAI will continue to provide solutions and help meet our partners’ needs for future growth.”

Related Content

Hexcel introduces mid-temp Flex-Core HRH-302 honeycomb core

Bismaleimide (BMI) option to serve complex curvatures and thermal management needs of military, commercial and UAM aircraft.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More