JEC 2017 – Aiming for Industrialization

The exhibit floor in Paris reflected composites’ move toward high-rate and high-volume production.

For me, the major themes at JEC were industrialization, thermoplastics and a dramatic increase in technologies and touted capability for Industry 4.0 production. Though I expect to blog more fully and/or publish print articles about the following companies in the near future, here is my tour of highlights from the 2017 JEC World exhibit floor:

Automated Preforming at 10-15 seconds per layer

I first encountered FILL Machine Engineering (Gurten, Austria) when touring nearby FACC (Ried im Innkreis, see my 2014 article). When I asked who supplied all of the automated NDT systems for composites, my tour guide answered, “You don’t know FILL?” I do now. FILL is a family-owned company with 715 employees, a turnover of app. 145 million € and additional facilities in Shanghai, China and Puebla, Mexico. It designs and supplies automated systems for production in metals, wood and plastics, the latter including industrial-scale production lines for composites, polyurethane and particle foam. In composites, FILL has produced units for handling of reinforcements and preforming, molding, machining and testing including NDT.

Designer of the Fill Multi-Layup System, Norbert Danninger, beside the exhibit booth video of this new preforming line in operation. SOURCE: FILL.

The Multi-Layup System is one of FILL’s latest developments, a patent-pending line for creating near net-shape preforms for high-volume composites parts production. It includes dual integrated material feeders and laying heads operating in parallel. The material feeders each unroll and cut tailored-length pieces — determined from the part’s CAD file analyzed by FILL process software — from multiple different reels of tape or tow.

Instead of a robot, a set of deposit rails receives the fiber tapes. The rails module includes a vacuum gripper with integrated heating strips so that it joins/consolidates the tapes as it collects and combines them into a tailored stack onto a moveable, segmented deposit table to which vacuum is applied. Benefits of the system include:

- High degree of flexibility because the laying heads and deposit rails can be arranged in any desired sequence to produce a complete fiber layer.

- Precise positioning and arrangement of the cut tapes with fiber orientation as directed from optimized digital design files.

- Trim waste is reduced dramatically vs. cutting preform layers from sheets of NCF.

- Very short cycle times of 10-15 seconds per layer due to multiple sets of material rolls being fed and a vacuum gripper that can collect and place all of the tapes per layer simultaneously, instead of one-at-a-time in serial fashion.

FILL is working now to further develop the system for 2.5D and 3D preforms for CFRP parts with minimal to zero forming steps required before molding. This system can be used for a range of materials, including prepregs, thermoplastic tapes or dry fiber tapes. The company is also pursuing how to use recently developed promising materials for aerospace applications and to refine the MultiLayup System for automating dry fiber 2D layups for RTM within the EUREKA project in partnership with IDEC AERO (Miñano, Spain) and its R&D subcontractor TECNALIA (Derio, Bizkaia outside of Bilbao, Spain).

According to the head of FILL’s composites competence center, Wilhelm Rupertsberger, customer-specific production trials of components are currently being completed based on inquiries received from FILL’s exhibition at the K show (Oct 2016, Dusseldorf, Germany). Lessons learned from these trials are being integrated into the final development of the prototype Multi-Layup System with commercial availability slated for end of 2017.

Fill also exhibited its LOWFLIP automated tape laying cell, developed as part of the EU-funded LOWFLIP project. Fill won a JEC award in 2016 for its work in developing this cost-efficient, flexible and automated process for producing composite components.

Fast RTM

Winner of a 2017 JEC Innovation Award in the process category, the Fast RTM platform is an automated production line developed by the Institute de Recherche Technologique Matériaux, Métallurgie et Procédés, better known as IRT-m2p (Porcelette, France), in strong collaboration with Pinette Emidecau Industries (PEI, Chalon sur Saône, France) and the following partners in France:

- Arkema

- Chomarat

- Compose

- Composite Integrity

- Hexion

- Hutchinson

- Renault

- SISE

IRT-m2p is part of the French national R&T institute system located near Metz. About 30% of its work focuses on composites. It has 75 engineers globally, but 10 work at the Porcelette site.

The Fast RTM system combines Pinette's new ECS-PRESS (Eco, Compact, Sustainable) short-stroke press with two 6-axis robots for material handling and compression resin transfer molding (C-RTM), a version of high-pressure RTM (HP-RTM) which uses gap molding to achieve shorter injection time for a 2-minute cycle — 40 s for press movement, 80 s for resin injection and cure. Its target is high-volume automotive production, with a 3 m2 (2m x 1.5m) part size.

|

|

The Fast RTM automated work cell, capable of 500,000 parts/yr and the glass fiber composite demonstration part shown at JEC. SOURCE: Pinette and CW.

As explained by Pinette president and CEO Jerome Hubert and IRT-m2p project manager Maxime Kowalski, the 2-min cycle time can deliver 500,000 parts/yr on a single work cell. Parts may be thermoset or thermoplastic, as demonstrated using Hexion’s (Columbus, OH, US) EPIKOTE epoxy and Arkema’s (Colombes, France) Elium modified acrylic thermoplastic. Kowalski explained that the part shown at JEC is not functional, but was defined by OEM partner Renault (Boulogne-Billancourt, France) to prove feasibility, a sort of sampler for geometrical complexity including change in thickness, double-curvature and stiffeners. Hubert stresses that both Renault and Tier 1 supplier Faurecia (Nanterre, France), made this program possible. Glass fiber noncrimp fabric (NCF) used in the part is from Chomarat (Le Cheylard, France). The Fast RTM process also uses Hennecke (Sankt Augustin, Germany) injection equipment and tooling from Compose (Bellignat, France), and was developed with expertise from Hutchinson (Paris, France), NDT specialists Composite Integrity (Porcelette, France) and thermalregulator, processing and big data systems knowledge from SISE (Oyonnax, France).

Hubert notes that Fast RTM is Big Data-compatible. “We have received requests from the market to provide this capability,” he explains, “which enables traceability of parameters including pressure, platen temperature, speed of mold closure, mold cycle time, etc.” He says this data is easily exported for analysis, quality assurance logs and building of each part’s digital thread. Kowalski adds, “We monitor the tooling temp and electrical energy consumption to predict cost of production. We can define the cost of each part.”

A key part of this cost and energy consumption awareness is the ECS-PRESS. Hubert explains that extra roof height is typically needed to accommodate HP-RTM presses (rule of thumb is 6m under crane). But customers want to use presses without special construction. Pinette responded with this short-stroke hydraulic press that uses many smaller cylinders under the platen vs. one large single up-acting or down-acting cylinder. The bolster moves down efficiently using servo-motors to lower the upper mold while the cylinders raise the lower mold. ECS-PRESS uses 50% less energy and 70% less hydraulic fluid for a 1500-tonne press at only 4.7m height vs. legacy presses at 7-8 m (2500-tonne press is also available). Placing the hydraulic cylinders underneath the platen also eliminates risk of leaks contaminating the mold and part surfaces vs. overhead cylinders. This press is also less noisy and compatible with RTM, HP-RTM, SMC, C-SMC and stamping/thermo-compression processes.

Fast FORM

Now the Fast RTM partners are working on a new project, Fast FORM, to develop an automated process for structural part preforms which achieves a 2-minute cycle time as well as 100% material usage/0% scrap. Pinette is developing specific equipment for this. There are also four new partners: Owens Corning (Toledo, OH, US), Coriolis (Queven, France), Peugeot PSA (Paris, France) and the ESI Group (Chartres-de-Bretagne, France).

Started in March 2016, FastFORM will last 60 months with a budget of 8.5 million €. It will use only dry textiles — e.g., NCF, woven, knitted fabrics — and UD material for selective reinforcement.

Magna Develops CFRP Subframe with Ford

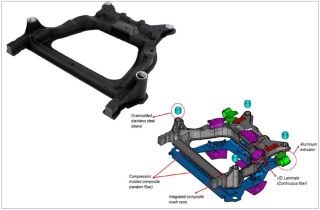

Magna (Troy, MI, US) promoted a carbon fiber composite subframe, developed in a collaborative program with Ford Motor Company (Dearborn, MI, US), which replaces 45 steel parts with two molded components and four steel inserts. The molded parts are bonded together using structural adhesive from Ashland Performance Materials (Columbus, OH, US) and structural rivets. A key part of vehicle structure to which the engine and wheels attach, a subframe contributes rigidity and has key crash management requirements. Prototype subframes made in-house by Magna are now undergoing component and vehicle-level testing at Ford. In a press event at the show, Magna Exteriors president Grahame Burrow explained that this subframe will be vehicle tested on a segment lead vehicle, but has not yet been attached to a specific model.

|

|

Magna/Ford front perimeter subframe for unibody vehicles made using EpicBlend CFS-Z SMC co-molded with EpicBlend CFS-Z w/0°-90° NCF. SOURCE: Magna and CW.

The subframe is made from EpicBlend sheet molding compound (SMC) which is compounded by Magna using chopped 50K carbon fiber tow from Zoltek (Bridgeton, MO, US) and vinylester resin modified in-house. Burrow says the vinylester gives good adhesion to the carbon fiber and also wets out the fiber well. The short-fiber SMC allows molding complex geometry, for example SMC overmolded steel inserts for body mounts and front points. Areas of high loading are reinforced locally with patches made from continuous fiber SMC, co-molded to the chopped fiber compound. The continuous fiber SMC is made using 6 plies of 0-90 noncrimp fabric and oriented as determined by CAD analysis using Fibersim from Siemens PLC (Waltham, MA, US). The oriented SMC is used only at high load points, for example, where the engine is attached and side areas where compressive and shear loads are at a maximum. The combination of the two SMC materials cuts 9.3 kg, a 34% reduction in mass, vs. a stamped steel subframe.

Though the prototype parts are layed up manually, in production all transfers would be automated as would placement of the oriented charge atop the chopped fiber SMC. “We started working with Ford on this program 8-9 months ago,” says Burrow, “and jointly developed the concept and tooling. We brought the tooling into our facility four weeks ago and started trialing demonstration parts. We are close to fully validating the target three-minute cycle time, aiming for 200,000 parts/year, but the process is easily scalable.” Burrow adds, “We’ve worked with Ford for decades. This is only one part of Ford’s lightweighting strategy.”

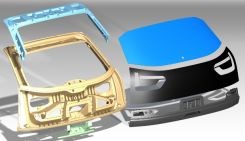

Organosheet is used to create a thin U-section on the beam of the Audi A8 front end made by Magna's Decoma Exterior Systems in Obertshausen, Germany. This multi-material front end cuts weight 20% vs. aluminum equivalent. SOURCE: Lanxess |

The inner shell of the BMW i3 lift gate module is made of long glass fiber reinforced PP. Magna delivers the module with all systems installed to the i3 assembly line from its factory in Liberec, Czech Republic. SOURCE: BMW |

When asked about recyclability of this part, Burrow notes that Magna is using recycled carbon fiber (RCF) in a different program. “It has gotten to be cost-effective,” he says, explaining the company’s partnership with Borealis targeting vertical body panels using thermoplastic olefin (TPO) reinforced with RCF, “so the parts are light and can be painted.”

Johannes Götzelmann, director of product & process development for Magna Exteriors Europe, explained that all divisions of Magna Exteriors work with composites, mostly glass fiber (GF)/polypropylene and GF/polyamide (PA) in structural and semi-structural parts, for example front end modules, carriers for grills, reinforcements for bumpers and lift gate modules. “We do a lot of hybrids,” he says, “combining injection molding with metal.” He points out two serial production parts running on the BMW i3, “And we have a front-end carrier that is injection molded GF/PA/metal/organosheet (woven) introduced five years ago,” Götzelmann says. “This is our first higher-volume thermoplastic composite structural part for the Audi A8.”

Mitsubishi Rayon Advances SMC and Prepreg Compression Molding for Auto Parts

Mitsubishi Rayon Co., Ltd. (MRC, Tokyo, Japan) highlighted its development of a new product combining short (2.54-cm long) carbon fiber sheet molding compound (CF-SMC) with noncrimp fabric (NCF). The CF-SMC is made by MRC and the NCF is made by Mitsubishi-owned fabric developer and producer TK Industries (Selbitz, Germany).

Mitsubishi Rayon Co., Ltd.'s global presence and supply chain.

SOURCE: MRC exhibit booth.

According to Akira Nakagoshi, general manager of the Composite Products Division for MRC, the NCF is also turned into a molding compound and the products can be run on the same line. The continuous fiber NCF provides high mechanical properties while the short-fiber compound is easily molded into complex shapes.

|

|

|

Demonstration part showing complex geometry of chopped-fiber SMC on back (left) with continuous-fiber molded using PCM on front (right). SOURCE: MRC and CW.

MRC’s SMC has been adopted for Toyota’s new Prius PHV (plug-in hybrid vehicle) because its advantages have earned high recognition from the automaker. Nakagoshi explains that these advantages include high-performance components with substantial weight reduction and excellent formability that enables complex-shaped components to be produced with the efficiency required for mass-produced vehicles. He add that with this adoption as an impetus, MRC will actively and extensively promote the use of its carbon fiber materials for automotive components.

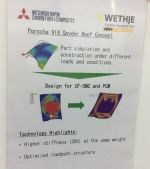

CF-SMC is also suitable for roof inner parts. Wetjhe Carbon Composites (Hengersberg and Vilshofen-Pleinting, Germany), which MRC acquired in 2014, has demonstrated the combination of CF-SMC and MRC’s prepreg compression molding (PCM) technology approach which cures in less than 10 minutes. “Normal prepregs cannot make such complex shapes,” says Nakagoshi, holding up a demonstration part featuring a complex-shaped back (CF-SMC) and smooth front easily identifiable as using PCM (see images below). “So we are combining PCM and prepreg technology,” he adds. Nakagoshi says production capacity for SMC is 3,000 metric tonnes/year in Japan and 6,000 tonnes/year in Germany once at full rate. Right now, the line in Germany is just beginning to ramp.

|

|

|

General manager Akira Nakagoshi holds up demonstration part for new CF-SMC and prepreg compression molding (PCM) technology (left). Adaptation of this technology for Porsche 918 Spyder roof concept increases stiffness by 30% at same weight vs. previous composite roof. SOURCE: CW.

MRC also announced it has acquired all the shares of Gemini Composites LLC (Seattle, WA, US) and made the firm a subsidiary effective March 1, 2017. Gemini Composites was established in 2012 by Dr. Paolo Feraboli who is known for his work in developing the Forged Composite technology.

“Dr. Feraboli’s work in qualifying short-fiber composite materials for structural parts at Boeing fits our direction for carbon fiber composites to expand,” Nakagoshi explains. “We started communications with Gemini in 2012, and Dr. Feraboli has now used our materials,” he adds, noting that both the Forged product name and Gemini Composites’ company name will be retained.

Voith Composites Automated Roving Applicator

Voith Composites (Garching bei München, Germany), formed in 2010, showcased its JEC 2017 Innovation Award-winning automated direct fiber placement machine, developed with Audi AG (Ingolstadt, Germany). The patented Voith Roving Applicator (VRA) feeds in dry carbon fiber tow, spreads into a 50-mm wide tape and applies powder, after which the tape is quality checked and cut. A pick-and-place robot with grippers builds up cut tapes into a net-shape preform with fiber orientation tailored to meet final part geometry and load requirements. The final carbon fiber reinforced plastic (CFRP) part is molded into 3D shape using HP-RTM.

Voith describes the VRA as scalable, with throughput on a single line doubled by adding a second pick-and-place robot. Multiple VRA units can also be placed in parallel. Voith Composites announced in 2015 that it had secured a contract to make a carbon fiber reinforced plastic (CFRP) part for Audi. That production is in the process of ramping, and though the company is dedicated to being a composites parts manufacturer, it is open to supplying preforms.

Voith has also worked with BMW AG (Munich, Germany) as part of the MAI AutoPreg project, a 1.5 million € program with additional partner C-CON GmbH (Munich, Germany) that ran from Jan 2015 until Sep 2016 as part of the Carbon Composites e.V. (CCeV) network/ MAI Carbon Leading-Edge Cluster. Its goal was to truly industrialize the 20-year old process dubbed carbon preimpregnated pressforming (CPP) which feeds in rovings, impregnates them with resin and then uses a winding process to develop plates which are then molded and cured into 3D parts via a thermoforming press. Development focused on an impregnator adapted to winding, new matrix materials, adapted automation technology and an appropriate handling system.

|

|

|

MAI AutoPreg project (top) and SMiLE demonstration part, a multimaterial load floor for automotive (bottom). SOURCE: carbon-composites.eu and CW.

Voith Composites also exhibited an automotive floor developed as part of the SMiLE project. The part features a VAR-developed sub-preform, thick foam core for seat attachment and thin core (termed “microsandwich”) for the footwell. Partners include Audi AG, FRIMO, BASF and Fraunhofer ICT.

Related Content

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More