JEC World 2016, the full report

CompositesWorld's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

- Wind/Energy

- Sustainability

- Automotive

- Sheet Molding Compound

- Carbon Fibers

- Biomaterials

- Out of Autoclave

- Workforce Development

- Electronics

- Molds/Tools

- Materials

- Glass Fibers

- Fabrics/Preforms

- Pressure Vessels

- Adhesives

- ATL/AFP

- Weaving

- Consumer

- Processes

- Epoxies

- Resins

- Thermoplastics

- Aerospace

- Natural Fibers

- Reinforcements

- Design & Tooling

- Marine

- Autoclave

- Construction

- Compression Molding

- Ketones

- Braiding

- Design/Simulation

- Prepregs

- RTM

- Curing

- Space

- Infusion

- Materials Testing

- Core

CompositesWorld sent two editors (Jeff Sloan and Sara Black) and a contributing writer (Donna Dawson) to JEC World 2016 in Paris in early March. Below is a full review of (almost) all that we found there. This is not an exhaustive report — the show is too large to be adequately covered by three people, but we think we captured the highlights. And whatever we missed, we missed only because we simply ran out of time.

SGL Group and the BMW 7-Series

Among the busiest, most closely studied exhibit at JEC World 2016 was the body-in-white structure for the BMW 7-Series, on display in the SGL Carbon SE (Wiesbaden, Germany) stand. This structure is pointed to as the future of composites use in automotive, where carbon fiber has been selectively applied in a mixed-materials strategy. The steel/aluminum/composite car features a B-pillar made with Hexcel carbon fiber and bonded to the vehicle with adhesive from L&L Products. It also features two carbon fiber roof arches, with foam core, molded with Hexion epoxy resin. If, in fact, automakers are becoming "material agnostic" as some of them claim they are, then selective use of different materials to meet different mechanical and asthetic requirements makes sense. Which means the BMW 7-Series likely is the first of many vehicles designed to use material in the same way.

BMW 7-Series B-pillar.

Stephen Tsai, José Daniel Melo and trace theory

Stanford University’s professor emeritus Stephen Tsai and Stanford’s visiting scholar José Daniel Melo hosted a 2.5-hour conference at the JEC World event, to introduce composite designers to basic “trace” theory and its application to laminate design. The theory, which CW has covered, was developed with Tsai and co-investigators Melo, a consulting professor; Alan Nettles, a NASA (Huntsville, AL, US) composite materials engineer and visiting scholar, both in the Department of Aeronautics & Astronautics at Stanford University (Palo Alto, CA, US); Dr. Waruna P. Seneviratne, technical director/scientist at the National Institute for Aviation Research (NIAR, Wichita, KS, US); Yasushi Miyano, professor of engineering at Kanazawa Institute of Technology in Japan (Ishikawa, Japan); and Jared Nelson, a doctoral research assistant from Montana State University (Bozeman, MT, US). They propose a radically new approach that reduces the physical testing required for composite material evaluation, thereby accelerating the development of design allowables for new composite materials and processing. According to the theory, trace of the stiffness matrix of an orthotropic material is invariant and embodies the entire stiffness relationship of the material. Trace is the material factor derived from the mathematical matrix that is generated for a composite laminate, considering the four stiffness properties of longitudinal and transverse Young’s moduli, plus one Poisson’s ratio and one in-plane shear modulus, transformed to a single, all-inclusive property.

Tsai says that in addition to the JEC conference, Stanford is offering a week-long, online workshop on trace theory in June; click here for workshop information and to register.

All-carbon fiber BMW hood

Solvay Composite Materials (Heanor, UK) debuted a novel all-carbon fiber composite hood that it helped develop for the BMW M4 GTS, in cooperation with fabricator C-CON GmbH (Munich, Germany) and automotive metals specialist Läpple AG (Heilbronn, Germany). Developed and prototyped in just nine months, the hood represents a substantial step-change in automotive parts fabrication and shows how composites fabrication can be adapted to fit within the established automotive manufacturing supply chain.

BMW, which has already made a name for itself with the liberal use of composite materials in the i3 and i8 vehicles, approached C-CON with the idea of converting the M4 GTS hood from aluminum to carbon fiber composites. C-CON, in turn, turned to Cytec (at the time not yet acquired by Solvay) for help developing the materials and processes required. Alex Aucken, global automotive director Industrial Materials at Cytec Solvay, says the short development window put tremendous pressure on all of the companies involved, but in the end, the materials and process developed produced a hood not only 40% lighter than its aluminum predecessor, but one that is also cost-effective and viable in other applications.

The 8-kg hood consists of a 1.2-mm thick Class-A outer panel bonded to a 1.2-mm thick inner structure, with additional carbon fiber composite reinforcements near two corners to support hinge components. The novelty of the hood is in its resin matrix and its layup. The former is an epoxy developed by Cytec for the application, called MTR 760. Layup, atypically, is provided by filament winding.

Aucken and Tim Wybrow, application research and engineering manager at Cytec Solvay, say that the process developed involves in-situ application of MTR 760 resin on a 24k tow carbon fiber just prior to filament winding around a 1m diameter mandrel, in an optimized angle and layer configuration. After winding, this prepregged layup is removed from the mandrel and then slit to create a flat blank, which is then cut to shape, either for the outer or inner panel. One filament-wound layup is large enough to provide material for up to three tailored blanks.

For consolidation and cure, a tailored blank is placed flat between two layers of thermoplastic film, which are clamped in place, under tension, by a metallic frame. Cytec Solvay calls this the double-diaphragm forming process that, says Aucken, obviates the need for preforming and allows the carbon fiber blank to take the shapes required — some very complex — with minimal wrinkling. The entire frame is then placed in a metallic mold in a compression press and cured in less than 5 minutes. Finished parts are cut and trimmed in preparation for assembly and bonding. C-CON does all of the filament winding and blank preparation. Läpple does the compression molding, trimming, cutting, and assembly.

Although technically the compression process is relatively straightforward, it is symbolic of a larger problem that the automotive and composites industries face: How to integrate composites molding processes with the metals-based legacy processes that the automotive industry employs?

In the case of the BMW M4 GTS hood, the task was to develop a composites fabrication process that could be adaptable to Läpple’s metal-forming machinery. This would allow Läpple, which has experience as a BMW supplier, to easily convert to composites fabrication without the capital equipment investment that might otherwise be required. For this reason, the M4 GTS hood is molded on a metal-forming press. “Optimizing the logistics of a metal pressing line was paramount for this project,” says Aucken. “We have to fit into the existing infrastructure,” says Wybrow.

The result is a hood that meets all of BMW’s requirements for cost, strength, stiffness and pedestrian safety. It has, says Wybrow, a void content of 1.2%, and its Class A surface is easily paintable. BMW is making only a low volume of M4 GTS models with the carbon fiber hood, but the aftermarket for the part is considerable given the hood’s compatibility with other M3 and M4 models. Further, the hood proves the viability of using filament winding as a layup process combined with standard compression molding.

Teijin's Sereebo compression molding process

Demonstrator part molded using Teijin's compression-based Sereebo process.

TEIJIN ARAMID BV (Tokyo, Japan) made public for the first time many details about its Sereebo high-volume composites manufacturing process. First announced in December 2011, the process was developed by Teijin in Tokyo and in cooperation with General Motors (GM) at Teijin's technology center in Auburn Hills, MI, US. Sereebo is designed specifically to meet the needs of the automotive industry to fabricate carbon fiber composite parts and structures at high volumes with short cycle times.

Eric Haiss, vice president of Teijin Advanced Composites America Inc. (Auburn Hills), told CW that the Sereebo process combines a nylon 6 resin matrix with a mat of chopped carbon fibers (length ~20 mm), which are preheated and then molded/formed in a standard compression molding machine in cycle times of 60-80 seconds. Haiss says Teijin cannot reveal the form the nylon 6 takes, except that it is integrated in the carbon fiber mat. In addition, the carbon fiber will be sized for the nylon 6 resin.

Parts on display on the Teijin stand at JEC indicate the Sereebo process is capable of producing parts with relatively deep draws and large curvatures, with no wrinkling (see images at left). In addition, changes in mat thickness allow for tailored fiber reinforcement to meet specific mechanical load requirements. Further, says Haiss, by varying the way the fiber is oriented in the mat, isotropic properties can be moderately controlled.

Data displayed on the Teijin stand at JEC indicate that parts made with Sereebo exhibit significant energy-absorbtion properties: 70 J/g, compared to 59 J/g for continuous carbon fiber composites and 20 J/g for aluminum.

Haiss says the Sereebo process will be used by Teijin to fabricate primary structure automotive parts for an undisclosed automotive program. The model year of the vehicle was not revealed. Teijin also would not identify the OEM involved, but Teijin's history of cooperation with GM makes that carmaker the most likely customer. Fabrication will be done in the United States, but a location has not yet been determined. Haiss did say that fabrication will not be done in Auburn Hills.

Teijin is scheduled to discuss Sereebo at CompositesWorld's Thermoplastic Composites Conference for Automotive (TCCA), June 15-16, in Novi, MI, US: www.tccauto.com.

Demonstrator part made using Teijin's Sereebo process, designed to show the deep-draw

capabilities of the process.

A&P Technology and QISO test data

A&P Technology Inc. (Cincinnati, OH, US) highlighted its trademarked QISO quasi-isotropic (0°, +/-60°) fabric, a slit braid material, which has enabled easy lay-up and provided superior performance for a variety of composite applications, says the company. And, it introduced a new database of QISO test data that allows a more comprehensive explanation of the benefits of quasi-isotropic fabric. A&P Technology teamed with Tencate Advanced Composites (Morgan Hill, CA, US) to compare laminates composed of QISO fabric, which were compared to laminates composed of woven fabric, both prepregged with TenCate’s highly-toughened TC275-1 epoxy resin. Coupon and panel testing proved QISO superior in mechanical properties and impact performance, say the company. Barry Meyers, vice president of technical services at TenCate Advanced Composites, says “Based on early discussions with A&P, we had a hunch that the combination of TC275-1 and QISO would result in improved performance, but we did not expect to see such a dramatic improvement in mechanical properties, compared to typical woven laminates. We have seen particularly high improvements in compressive strength and open hole compression.” QISO’s quasi-isotropic architecture has the same properties in every direction, so orientation of the fabric is not a concern, allowing for simple layup and a reduction in scrap. QISO is offered in a variety of widths and weights.

Hexcel annual press conference

Hexcel (Stamford, UK) held its annual press conference at JEC and reported financial and other news. Nick Stanage, chairman, president and CEO of Hexcel, reported the company had $1.861 billion in 2015 revenue, with 45% of that coming from the US, 39% from Europe and 16% from ROW. Stanage says Hexcel is the largest aerospace weaver in the world and “virtually” the largest honeycomb manufacturer in the world. Hexcel places $5 million worth of material on every A350 XWB that Airbus manufactures. In April Hexcel opened a new R&T Innovation Center in Duxford, UK, for the development of fast deposition, infusion, fast-curing and advanced modeling technologies, plus low-temperature cure systems for thick prepregs. The industrial market is the company’s fastest growing segment, led by Tim Swords, VP and GM industrial. He commented on Hexcel’s recent acquisition of Formax (now branded Hexcel Reinforcements UK), emphasizing the lineup of multiaxials and NCFs that the business brings. Swords also discussed the use of HexPly M77 UD carbon fiber prepreg in the BMW 7-Series B pillar, manufactured in a 90-second-cure process, with automated cutting and in-situ inspection, to produce 500 units/day.

ELG Carbon Fibre and recycling

Frazer Barnes, MD of ELG Carbon Fibre Ltd.(Coseley, UK), emphasized his company’s Carbiso line of material forms derived from the firm's pyrolosis-based composites recycling technology. He pointed out the need for the development of material characteristics for fibers derived from recycling processes. “We need to give engineers the confidence to use the material,” Barnes says. “The best way to do that is to show applications.” ELG produced 1,080 metric tonnes of recycled carbon fiber in 2015, mostly short chopped fibers up to 6 mm long. Applications include injection molding processes for automotive and electrical/electronics. ELG also makes a line of 90-600-gsm mats comprised of carbon fiber or a carbon fiber/polypropylene mix. ELG hopes, in the next five years, to establish a larger production facility in Germany to help it achieve total capacity of 6,500 tonnes/year.

ELG's 90-600-gsm Carbiso mats are derived from recycled carbon fiber.

Arkema demos Elium thermoplastic boat hull

Arkema Inc.(Colombes, France), in addition to news of its collaboration with Polystrand (Englewood, CO, US), had as the centerpiece of its stand a complete carbon fiber sailboat hull made with the company’s trademarked Elium liquid thermoplastic resin. The vessel, dubbed Mini 6.50 Arkema 3 Innovation, served as a prototype or demonstrator, to showcase not only the infused hull but other Arkema products as well. Boatbuilder Lalou Multi, known for its ocean racing endeavors, built the hull using the easily-processed Elium, which is liquid at room temperature and suitable for infusion and resin transfer molding (RTM), but has the strength and stiffness of epoxy with 50% higher toughness, says the company. The fact that Elium is a thermoplastic makes the hull recyclable at end of life, a huge benefit according to Lalou Roucayrol, head of the Lalou Multi organization. Watch a video about the boat hull and Elium here: http://www.sailingscuttlebutt.com/2016/03/09/video-boat-building-recyclable-composite/.

CSP, Mitsubishi Rayon cooperation

Continental Structural Plastics (CSP, Auburn Hills, MI, US) and Mitsubishi Rayon Co. Ltd. (MRC, Tokyo, Japan) announced on the second day of the JEC World show that they have established a memorandum of understanding (MOU) regarding the development and manufacturing of innovative carbon fiber structural components for the automotive industry in North America. Under the MOU, CSP and MRC have agreed to commence detailed studies through which the two companies intend to substantiate the establishment of an equity-based joint venture.

Specifically, the new joint venture will produce compression molded components made from carbon fiber-reinforced plastic materials, which could include carbon fiber sheet molding compound (SMC) and prepreg carbon fiber compression molding (PCM). Components will include Class A body panels, as well as non-class A structural automotive applications including pillars, engine cradles or supports, radiator supports, frames and rails, bumper beams, underbody shields, door inners and intrusion beams, say the two companies.

“This agreement represents a tremendous opportunity for us to work jointly with one of the world’s largest manufacturers of carbon fiber to introduce a new generation of lightweight components for the auto industry,” said Frank Macher, chairman and CEO of CSP. “The expertise that exists between our two companies will enable us to develop and bring to market carbon fiber components that are cost-effective for mass production.”

“By working together with Continental Structural Plastics, we gain access to tremendous expertise in composites, and in developing structural applications for light vehicles,” said Akira Nakagoshi, general manager, Composite Products Division at MRC. “We look forward to the opportunity to further expand MRC’s composite material technologies among automakers in North America, and are hopeful for creating better relationships among people, society, and our planet.”

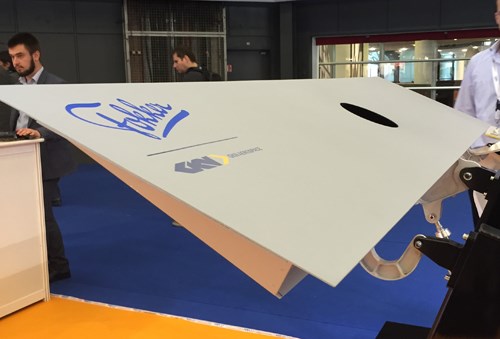

Fokker thermoplastic spoiler demonstrator

Fokker Aerostructures BV (Hoogeveen, The Netherlands), a GKN Aerospace company, demonstrated at its stand a thermoplastic composite aircraft demonstrator spoiler, fully functional and consisting of only three parts: top skin, bottom skin and a single spar. Material is carbon fiber/polyetherketoneketone (PEKK) AS4D/PEKK unidirectional tape, supplied by Solvay Cytec (Woodland Park, NJ, US). Arnt Offringa, director of Fokker Aerostructures research and development, says that skins have additional plies at load introduction areas, and vary in thickness from slightly more than 1 mm to 4 mm (about 10 to 30 plies). Additionally, skins are stiffened with simple hat sections, co-melted with the skin during short-duration autoclave processing, which is used to heat and consolidate the parts to prevent porosity. The flap’s trailing edge has an integral edge stiffener formed by simply folding the top skin over the lower skin.

Fokker-developed end-effector on a thermoplastic tape layer manufactured by Boikon.

Fokker also announced that it has licensed its Fokker-developed end-effector that features 35,000-Hz ultrasonic heating capability to a partner machine builder and automation company, Boikon (Leek, The Netherlands), which displayed automated thermoplastic blank production in the demonstration area of the show. The Falko automated layup head is, according to Boikon, the world’s first layup system based on continuous ultrasonic tacking technology; more information on the automated thermoplastic layup machine is available here: www.fiberplacement.com/#/automated-lay-up/.

Thermoplastic tapes, laid by the Boikon machine.

MTorres and hybrid automated tape laying

Visitors were plentiful at automated equipment manufacturer MTorres (Torres de Elorz, Spain) busy stand. The company recently announced a new generation of hybrid automated tape laying (ATL)/automated fiber placement (AFP) solutions, specifically for wing skin fabrication, which has reportedly tripled productivity, and reduced scrap significantly. The new concept means that the 24-course ATL head can be interchanged with the AFP head, in under 2 minutes. According to the company, fiber placement of the wing skins is faster and more efficient than tape laying, since tows are cut on the fly without stopping with MTorres’ patented rotary cutting system. And, the machine gantry has been redesigned for the extreme accelerations possible with AFP. The ATL heads can be utilized for additional tasks, such as laying fiberglass or copper mesh plies, in the same manufacturing cell, improving productivity and logistics, says the company. MTorres is also a key equipment supplier to the Fundacion para la Investigacion, Desarrollo y Aplicaciones de Materiales Compuestos (FIDAMC) located near Getafe, Spain, a collaborative research and development center for aerospace composites supported by Airbus and local Spanish government agencies. CW will be following an ongoing FIDAMC project investigating the feasibility of an all-thermoplastic wing with integral welded stiffeners. MTorres will supply the automated fiber placement (AFP) head with laser heating for the demonstrator project.

Huntsman and fast-cure epoxies

Huntsman Advanced Materials (The Woodlands, TX, US) announced at JEC World 2016 that it has developed a new epoxy resin system and a novel, cost-efficient compression molding process, to facilitate the simple production of structural composite parts, and enable cycle times as low as one minute without any further post-curing for high-volume applications such as automotive.

Currently, a trademarked ARALDITE is used to manufacture the BMW i-Series of cars. With a cure time of two minutes at 130°C, this system gives a total cycle time of around two minutes 30 seconds. However, the latest rapid-cure ARALDITE epoxy system provides a cure time of just 30 seconds and displays a higher Tg, thus enabling robust processing up to 150°C and press cycle time of only one minute, without any further post-curing of the part. Following curing, the epoxy system displays a tensile elongation in excess of 5% with a Tg of 120°C.

To complement this new epoxy system, an innovative and simple Dynamic Fluid Compression Molding (DFCM) process has also been developed by Huntsman, which eliminates high-pressure injection and in many cases, even the need for a preform. Resin impregnation occurs through-thickness, greatly reducing the potential for fiber displacement, a common problem with resin transfer molding (RTM). Company tests show reduced void content of laminates in comparison to conventional wet-compression molding (WCM) processing, and porosity of less than 1%, making it comparable to high-pressure RTM (HP-RTM) or autoclave, even in deep draw parts. Fiber volume content of 66% can be easily achieved with no special processing conditions. The new DFCM process means lower mold pressures and a lighter press, plus no need for a high-pressure injection machine. Plus, DFCM eliminates resin waste since no surplus of resin or fiber is required to remove air from the part. The new process allows fast processing of thermoset parts, without the expenses of prepreg and higher-priced thermoplastic materials.

Henkel automotive and aerospace advances

The BENTELER-SGL-made composite leaf spring (pale green) is visible in the Volvo XC90 mock-up in the Henkel stand. The leaf spring is glass fiber infused with Henkel's Loctite MAX 2 polyurethane resin.

Henkel AG & Co. KGaA (Düsseldorf, Germany) emphasized automotive and aerospace material technologies on its JEC stand. On the automotive side the company featured a glass fiber-reinforced composite leaf spring based on Henkel’s polyurethane matrix resin Loctite MAX 2, used in the chassis of the new Volvo XC90, a premium crossover SUV; the platform of this vehicle is expected to be applied to other Volvo cars in the coming years. Frank Kerstan, global program manager automotive composites, says BENTELER-SGL is making the leaf springs via resin transfer molding (RTM) in 30-second cycle times. With eight to 10 leaf springs produced in each mold, BENTELER-SGL plans to manufacture up to 500,000 leaf springs per year by 2018. On the developmental side, Kerstan says Henkel is working on several intriguing technologies, including a urethane-based adhesive for multi-material automotive bonding applications that have a CTE mismatch. Also in the works is an RTM-based molding system using urethane resin that allows for the fast production of Class A surface body panels. This is done, says Kerstan, by use of a double-injection process in which the second injection creates the high-quality part surface that Class A requires.

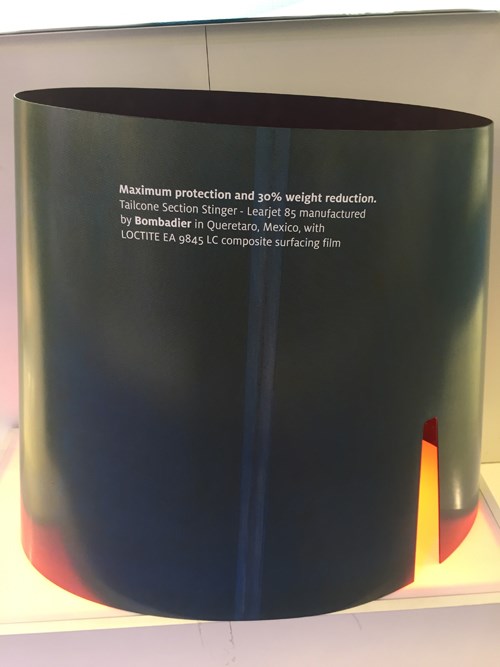

This tailcone section stinger is from the Bombardier Learjet 85 and uses Henkel's Loctite EA 9845 LC surfacing film.

For aerospace, Bjorn Balien, EMEA business development manager aerospace, reported that Henkel’s Loctite EA 9845 is being validated as a surfacing film to provide lightning strike protection and improved surface finish. The film features embedded metallic mesh, obviates the need for sanding, is UV tolerant, resists discoloration, is ready for painting and resists paint strippers used in repainting operations. Compared to alternative materials, Henkel says Loctite EA9845 offers up to 30% weight savings.

Danobat and automated fabric placement

Danobat S. Coop. (Elgoibar, Spain), a division of machine tool manufacturer DanobatGroup, featured its ADMP (Automated Dry Material Placement) machine and head. Originally developed several years ago for a wind blade manufacturer to lay down fabrics at speeds up to 110m per minute, the ADMP can lay woven and multiaxial fabrics or dry tape with no distortion or sleaze, thanks to its proprietary pick and place capability. The company says 5- or 6-axis configurations are available, to handle fabric widths up to 2m or more, as well as to cut ply patterns; cutting is performed simultaneously with head motion, says the company, that is, the head doesn’t stop. The machine head automatically aligns, deposits and cuts fabric, can apply tacky spray if required on curved molds, and is configured for inline inspection and wrinkle detection as well as completely automated roll changeover and resupply. Web tension is programmable to ensure that each material form is placed under optimum conditions.

Magna Steyr, Katcon partnership

Günter Wolfsberger, product manager composite fiber technology at Magna Steyr (Graz, Austria), and Carlos Garza, operations manager at automotive parts manufacturer Katcon Advanced Materials (Santa Catarina, Mexico), announced plans to work together to develop a manufacturing line to fabricate automotive body panels using glass fiber/polyurethane skins around a paper honeycomb crushed core. The system conceived would use Hennecke (Sankt Augustin, Germany) sprayup technology and could produce up to 100,000 units per year. Wolfsberger and Steyr discussed a specific demonstration to make a 14-kg BMW M3 car hood on a fully automated line that could produce one paint-ready, Class A hood every 280 seconds. Such a hood would be 66% lighter and 9% less expensive than its steel predecessor. This system is notional at this point, but Wolfsberger and Katcon say they have attracted the interest of several automotive OEMs.

FMG and aerocomposites outlook

Adrian Williams, co-founder and MD, Future Materials Group (FMG, Cambridge, UK), talked to CW at JEC about research FMG has been doing on the potential for increased composites use in aerospace and automotive applications. Williams talked specifically about composites use in the fuselage of a redesigned Airbus A320 or Boeing 737 single-aisle aircraft. The argument has been that throughput requirements and skin thickness limits in a single-aisle aircraft might make aluminum the better choice. Williams, however, suggests that airlines (customers) might favor a composites fuselage given that material’s better performance in maintenance and repair. In short, he says, airlines are learning with the 787 and the A350 XWB that composites simply a better, more durable, easier to maintain material. In automotive, Williams notes that carbon fiber currently represents <0.1% of the automotive materials market, which means that even a modest increase in carbon fiber use in this market could dramatically increase demand for the material. For instance, Williams says that if 1 kg of carbon fiber were included per mass market car, the carbon fiber market would increase from US$250 million today to US$6.5 billion. To satisfy this level of demand, the carbon fiber industry would need to build a new carbon fiber manufacturing line every two months.

Hexion and high-volume autocomposites

Each BMW-7-Series car uses two roof arches, made via HP-RTM with Hexion's Epikote Resin TRAC 06000 epoxy. Build rate is 80,000 units/year.

Dr. Francis Defoor, global market segment leader transportation at Hexion (Columbus, OH, US), discussed the featured part on the Hexion stand, the carbon fiber roof arch for the BMW 7-Series, made via HP-RTM with Epikote Resin TRAC 06000 epoxy. It uses a proprietary core technology and offers a cure time of about 60 seconds, Defoor says. The build rate right now is 80,000 units/year, with a target of 100,000-200,000 units per year, he says. Hexion, like many other material suppliers, is also establishing a research technical center, in Germany, to develop HP-RTM, liquid compression and compression molding. Thinking more broadly, Defoor argues that composites fabricators for automotive are still grappling with efficiency and cost requirements imposed by OEMs, but he believes that composites cycle time challenges have largely been solved. What remains, he says, is to solve material handling challenges, which will require more intense application of automation and robotics.

TeXtreme and spread tows for sporting goods

Spread tow reinforcements specialist Oxeon AB (Boras, Sweden) featured its line of TeXtreme fiber products. The company’s spread tow reinforcements have been applied to products and structures in the aerospace, car racing, marine, industrial and, particularly, sporting goods markets. Oxeon says the material is often credited with helping fabricators achieve an additional 20 to 30 percent weight savings over traditional carbon fiber reinforcements. In one example, protective headwear manufacturer Giro Sport Design recently announced the Avance MIPS, an innovative ski racing helmet made with TeXtreme. “In development of the Avance MIPS ski helmet, TeXtreme has enabled us to create an ultralight shell that’s tougher, stiffer and stronger than anything Giro has previously offered. Most importantly, TeXtreme provides impressive high-energy impact management,” says Mattia Berardi, Giro Ski’s product manager. According to Berardi, “The Avance MIPS outer shell is constructed from TeXtreme carbon fiber fabrics. TeXtreme’s wide, flat tapes fit tighter together and remain straighter than the round tows found in conventional carbon fiber materials, and thus require less resin needed to bind the fibers together.”

Bell Helmets' Pro Star model uses TeXtreme spread tow carbon fibers.

Also on display at the booth was a new Pro Star motorcycle helmet from Bell Helmets. Chris Sackett, vice president of Bell Powersports, says: “For the new Pro Star we wanted to take shell technology to the next level and by using the ultra-thin TeXtreme carbon fiber material we managed to engineer our best shell ever. The unique characteristics of the TeXtreme material enabled us to take out 20% of the weight and still have the same high level of performance.”

In addition to helmets, TeXtreme is currently used in Formula 1, NASCAR and America’s Cup racing, as well as in the manufacture of bicycles, golf shafts, tennis racquets, surf boards, rowing shells, skis and snowboards – along with various industrial and advanced aerospace applications.

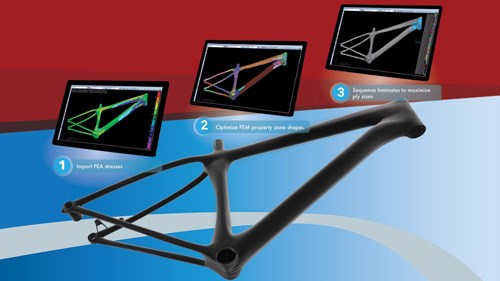

Streamlined optimization software from Collier

HyperSizer Express software from Collier Research simplifies composites design.

Collier Research Corp. (Newport News, VA, US) showcased its newest version of its HyperSizer optimization software, called HyperSizer Express, which delivers key capabilities of the full professional version of HyperSizer in a user-friendly package aimed at the composite engineer. As explained by Collier’s Bertram Stier, a research engineer focused on advanced composites, a customer’s finite element analysis (FEA) is first imported (Express is FEA-agnostic and most products are compatible). A streamlined, menu-driven “wizard” interface then guides the user through the analysis process, which produces optimum composite laminates that satisfy all analyses to all load cases, fulfilling strength and stiffness requirements, in as little as 30 minutes. Stier says the automatically updated model will arrive at the minimum weight with global plies and stacking sequences identified, layer by layer, with fully-manufacturable laminate designs: “HyperSizer Express finds the best location for monolithic laminates versus cored laminates, for example, plus optimal fiber direction and ply thickness.” The software can also handle designs with prepreg ply patches. HyperSizer Express is explained further here: http://hypersizer.com/download.php?type=pdf&file=HyperSizer_Express_Brochure.pdf.

CeraCarbon ceramic-coated laminate tubes

Roeland Coumans of CeraCarbon (Stein, The Netherlands) described a new material, called CeraCarbon, consisting of carbon fiber laminate tubes coated with a ceramic material. Since a patent is pending, specific details were few, but Coumans related that his product has already been adopted by Moto GP motorcycle racing teams, for suspension elements that typically see wear and abrasion. CeraCarbon suspension elements are 75% lighter, saving 1.5 kg in unsprung weight, a huge advantage. He related that aircraft landing gear elements and helicopter blades would be promising applications.

Acell construction panels

Acell Industries Ltd. (Dublin, Ireland), developer of a cost-effective architectural panel technology covered previously in CW (www.compositesworld.com/news/acell-architectural-project-completed), has announced an innovative building fire suppression system it calls Smart Panel, as well as a new North American partnership that will bring its roofing panel concept to market. Smart Panel is a cored architectural panel that contains a proprietary fire suppressant paste. The paste material is connected via electrical wires to a conventional smoke alarm, and the panel can be situated in walls or the ceiling of an interior space. When triggered by the smoke alarm, the paste undergoes an exothermic reaction and effectively blasts the resulting powder material onto the fire through a Venturi effect, extinguishing it within seconds. The safe, instantly deployable, rapid-response fire suppression system tackles virtually all types of fire, leaving zero residue and zero property damage in domestic applications, says the company. The chemical mixture does not require oxygen, which means that even after the powder has deployed people can still safely exit the room. The company is bringing Smart Panel to market in part because, as of April of this year, all homes in the United Kingdom will be required to have fire suppressant systems, either water sprinklers or a powder-based system like Acell’s. A video of the panel in action during a fire test can be seen here: https://vimeo.com/96663280.

Acell also revealed that it has signed a joint venture with a North American residential roofing manufacturer to market its composite roofing panels, designed to replicate the look of slate or tile, at a fraction of the cost and weight. Four production plants for Acell roofing will be built in North America, and the product will be part of the unnamed partner’s product portfolio. The company recently unveiled its new Web site, at acelltec.com.

Coriolis and automated fiber placement, engine mounts

Coriolis featured engine mounts soon to be in series production.

Robotic system and software supplier Coriolis Composites Technologies SAS (Quéven, France) featured at its stand several automotive projects, in which company chief technical officer Alexandre Hamlyn says the company has been involved for three years. On display was a net shape flat preform for the Audi A8 B-pillar, produced with unidirectional dry carbon fiber tape (with a binder) using a 16-tow Coriolis head, and made via high-pressure resin transfer molding (HPRTM) with virtually no scrap. Hamlyn says part development included linking Coriolis’ robotic layup software with mold forming simulation programs including AniForm (Enschede, The Netherlands) to achieve the best fiber orientation in the flat preform to create the final part shape and performance. The part, currently undergoing qualification, can reportedly be made in approximately 2 minutes, and formed in 20 seconds.

Also on display were engine mounts produced by Coriolis as part of a cooperative project, called DYNAFIB, for automotive tier supplier Cooper Standard (Novi, MI, US), which has a facility near Coriolis. Here’s a link to a recent CW article about DYNAFIB and activities of the numerous project partners: http://www.compositesworld.com/articles/dry-fiber-placement-surpassing-limits. The composite engine mounts, 50% lighter than benchmark steel parts, are made by laying glass/polyamide prepreg (pigmented black) joined to form a loop, as shown in the photo, which is then assembled over attachment points and subsequently overmolded (the orange-pigmented plastic) to form the final mount part. Hamlyn says the parts will be in series production soon: “We’re transferring our composites know-how from aerospace, where we started, into the automotive sector.”

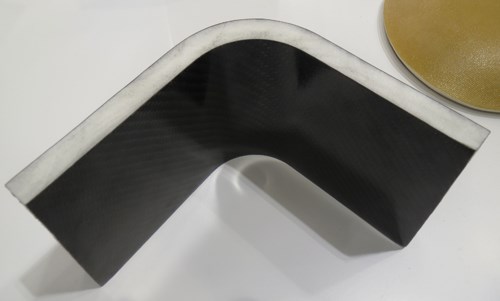

Munich Composites braids for field hockey sticks

Munich Composites used braided preforms to solve fiber wrinkling in the elbow of field hockey sticks.

Martin Stoppel, commercial director at Munich Composites (Munich, Germany), featured his company’s expertise in preform braiding with the exhibit of a new field hockey stick that Munich Composites developed for the Ritual brand. The braiding, says Stoppel, minimizes wrinkling at the stick’s elbow and thus boosts strength properties. The stick will be manufactured by Munich Composites in a highly automated process, making the stick cost-competitive with field hockey sticks manufactured by hand on low-labor-cost countries.

Mitsubishi Rayon pitch-based carbon fiber

Automotive driveshafts fabricated with Mitsubishi Rayon's DIALEAD pitch-based carbon fiber.

Mitsubishi Chemical Carbon Fiber & Composites Inc. (Tokyo, Japan) pitch-based carbon fiber, trademarked DIALEAD, is being employed in several recent automotive driveshaft application projects, on display at the company’s stand at JEC World. Shown were three all-carbon composite driveshafts, including one for the Chevrolet Corvette, the BMW M3/M4 and a Nissan Motorsports race car. Pitch-based carbon, rather than PAN-based, was essential to the projects, says the company, because of its higher stiffness. “These are highly engineered tubular structures, with high longitudinal stiffness,” says Mike Rainaldi, DIALEAD’s sales director. “They utilize multiple raw materials and innovative laminate constructions to achieve desired performance. Designing with DIALEAD pitch fibers requires not only understanding fiber performance but understanding how various materials interact and how best to sequence materials to achieve such performance.”

NetComposites and rapid, automated thermoplastic tape layup

The Stellar Project, a consortium led by UK’s NetComposites Ltd. (Chesterfield, UK) that includes Fraunhofer IPT (Aachen, Germany), HBW-Gubesch Thermoforming GmbH (Wilhelmsdorf, Germany), and others, is aimed at developing rapid, automated thermoplastic tape layup, in selective areas for more cost-effective parts, says NetComposites managing director Joe Carruthers. NetComposites showed the fruits of the project group’s progress with samples of the thermoplastic tape material, prototype parts and a demonstration of the selective tape laying concept. Carruthers says any polymer is possible, and that NetComposites is producing the tapes in widths from 6 to 25 mm. The group has developed a tape laying head and roller, equipped with a laser for in situ consolidation, with partner firms AFPT GmbH (Dörth, Germany) and CGTech Ltd. (London, UK), and a major goal is to develop a work space with two robots working in tandem, producing parts with virtually zero material waste. Three demonstration projects are in the works: a wing profile, an automotive part (with partner firm Toyota) and a sport skateboard.

Carruthers also pointed out a second NetComposites consortium project: Ecogel Cronos, comprising 13 partner firms, aims to develop a powdered gel coat for high-rate processing. The project is developing new techniques for placing an eco-friendly coating for composites, one without styrene, in heated molds, which still delivers good cosmetics at a lower cost compared to traditional gel coats. The powdered gel coat concept has the potential to reduce production costs by 25%, he says, with a 30% reduction in raw material consumption and a much longer shelf life. Plus, use of a powder can reportedly reduce gel coat thickness by 70%. For more information about the Ecogel Cronos project, visit the Web site: www.ecogelcronos.eu.

Pinette Emidecau Industries' turnkey compression system

The fully-automated Camso plant in Vietnam

Pinette Emidecau Industries (PEI, Chalon Sur Saone, France) director general Jérôme Hubert announced on the first day of the show that the company has successfully completed a turnkey plant in Vietnam, near Ho Chi Minh City, for a Canadian customer, Camso (Magog, Quebec, Canada). Camso produces rubber and polymer composite solid wheels and tracks for recreational vehicles and larger industrial vehicles. Under a tight deadline, Pinette was charged with designing and equipping the entire fully automated Camso production facility with nearly 100 machines in total, for all processing steps, says Hubert.

The €15 million ($16.7 million USD) project was designed, constructed and commissioned in 24 months, and involved more than 400 people. It included the rough delivery of 350T and 600T hot forming presses with temperature control, automated tool loading and unloading, as well as automated loading and unloading manipulators and metal grinding machines. PEI also delivered full automation and control systems. In the role of general contractor, Pinette PEI was responsible for the overall project management including engineering and design, supply chain management, construction and commissioning.

Hubert explains that the project represented a challenge due to the large scope of knowledge required, the distance involved and its multi-cultural facet. Despite these risks, “Our single-source approach, methods and processes enabled us to deliver the complete turnkey plant on time while meeting the highest standards in safety and quality.”

Pinette will offer on-site support and training of local engineers to Camso as production ramps up. The plant’s grand opening occurred on schedule on March 7 in Vietnam, which Hubert attended, the day before the opening of the JEC World event. According to Hubert, more turnkey plants are in the pipeline.

Polystrand, Arkema and thermoplastic prepreg tape

PolyOne Advanced Composites (Englewood, CO, US), a subsidiary of Gordon Holdings (Montrose, CO, US), announced that advanced materials company Arkema (Colombes, France) will begin selling Polystrand’s trademarked range of glass fiber-reinforced thermoplastic prepreg tape products in Europe. These high-performance materials are used in thermo-compression, thermo-stamping and lamination processes, enabling lightweight, recyclable and structural composites for the automotive, transportation, energy, consumer and construction markets. Polystrand’s tapes join Arkema’s trademarked Elium reactive thermoplastic resin for resin transfer molding (RTM) and infusion, AEC Polymers structural adhesives for composite to composite and metal to composite bonding and assembly.

Polystrand tapes are continuous glass fibers impregnated by polymers including polypropylene, polyamides and fluoropolymers. Tapes have outstanding properties in terms of stiffness, strength and impact resistance. Polystrand’s X-ply prepreg multi-ply tapes present the advantage of higher mechanical performances due to the absence of crimp, and are already used in many applications in North America, for example in the automotive industry to reinforce front ends. Over-molding with short-fiber compound is possible to integrate functions in the composite part or to locally reinforce short-fiber composites. These continuous fiber materials bring endless opportunities to manufacture structural thermoplastic composite parts, say the two companies.

Chomarat products for cured-in-place pipe and sport

Chomarat (Le Cheylard, France) offered two new products at its stand. ROVICUT is a stretchable woven reinforcement intended for cured-in-place piping (CIPP) applications, developed in collaboration with Reline Europe (Rohrbach, Germany), a well-known CIPP supplier and sleeve producer. According to Chomarat, the ROVICUT is unique, in that because it conforms much more easily to the shape of the worn metal pipes, CIPP sleeves can be made with less material, saving weight and making installation easier, plus ultraviolet cure can occur faster. Chomarat worked with Reline to optimize the material for Reline’s Alphaliner 1800 machine line for large-diameter pipes, where sleeves must be as thin as possible to avoid adding too much weight to the aged structure.

Also on display was the company’s well-known, patented C-PLY non-crimp multiaxial carbon fiber reinforcements made with spread tows that reduce areal weight. Chomarat announced that ski manufacturer Dynastar has lowered the weight of its Mythic 87 skis by 26%, with the same mechanical performance, thanks to the C-PLY material. According to Dynastar, the Mythic 87 ski is the company’s lightest.

A. Schulman on Citadel acquisition

Bernard Rzepka, president and CEO of A. Schulman Inc. (now LyondellBasell) discussed his company’s recent acquisition of Citadel Plastics, noting that A. Schulman had found that the polyolefins market, where it is well established, was crowded and offered little opportunity for organic growth. In search of diversity, it started looking generally at the composites market, and more specifically at Citadel. The company likely will make other acquisitions in the next couple of years, Rzepka says. In the meantime, A. Schulman is opening a new innovation center in Ohio to help customers with applications engineering and development. That effort will be led primarily by Wisdom Dzotsi, VP and GM, USCAN engineered composites.

RocTool high-volume manufacturing demonstration

RocTool CEO Mathieu Boulanger explains how his company's induction heating process is used to mold a carbon fiber/thermoplastic epoxy panel.

RocTool's (Le Bourget du Lac, France) demonstration was a very fast induction heating of a carbon fiber/thermoplastic epoxy part, up to 190°C/374°F, with a cycle time of 2-3 minutes. The part heated up for about 1.5 minutes and then cooled for about 30 seconds. It was cool enough to remove and handle without gloves. It also applied pressure up to 10 bar on the part demonstrated, and RocTool claims pressure up to 20 bar is possible. The matrix demonstrated was an epoxy slightly modified with a thermoplastic. The process will work with standard epoxy or other thermosets in less time, RocTool says, perhaps as quickly as 1.5 minutes.

The bottom tooling mold is rigid and can be made from nickel, steel or Invar, while the top mold is a flexible bladder. When the flexible top mold is closed over the rigid bottom, the top forms itself to the rigid mold and applies pressure. The mold is heated by an automated system. When the mold is opened, the part lifts with the top mold and is removed from it, rather than from the bottom tool.

With current technology this system can achieve parts up to 6m2; for a larger part the company would have to advance or adapt the technology. RocTool sees this as ideal for a startup company that wants to get into composites and doesn’t want to invest in ovens, autoclaves or other heated tooling options.

Autodesk and data-driven design

Autodesk's (San Rafael, CA, US) Massimiliano Moruzzi updated CW on his company's efforts to help optimize design software to meet the unique needs of the composites industry. First up is a "smart material" that consists of a layer of conductive nanomaterial on a laminate that sends signals to Autodesk software via Bluetooth or wi-fi. The technology could conceivably detect pressure change or delamination and then generate an alert for the user/operator.

From the design concept side, Moruzzi says Autodesk has begun research on what it calls a goal-driven optimizer. Through this software, the designer would establish product performance and mechanical goals and establish design problems, but do so without use of a preconceived shape or material. The software would then create the shape that meets the design criteria. This system, says Moruzzi, could work with a variety of material types, including composites and metals. "The DNA of the material dictates the design," says Moruzzi. "The design does not dictate the material." This software is an Autodesk internal product right now, but the company is looking for industrial partners to help bring it to maturity and commercialization.

AGY glass fiber advancements

AGY is enthusiastic about its L-glass yarn products, which it states are bringing significant advances in high-speed printed circuit board (PCB) applications. L-Glass offers lower dielectric properties, allowing higher speed data compared to E-glass PCBs, says Victor Gu, sales & marketing director for Asia Pacific. Gu says he foresaw the need for faster data transfer when he considered the vast range of information that will be stored in the “cloud” as new technologies bring larger amounts of data to everyday life, along with new technologies in sensors for automotive, and growth in handheld consumer electronics.

AGY L-glass has been on the market for three years and is now adding capacity to meet the increasing demand. Different types of fabrics are being made to satisfy the needs of base stations for mobile communications as well as high speed servers used in companies such as Amazon, Google and others that are processing huge amounts of data or using large volumes of cloud storage. Various resin companies supplying these markets are now fine-turning matrices for best performance and AGY is looking at the second generation of L-Glass type products.

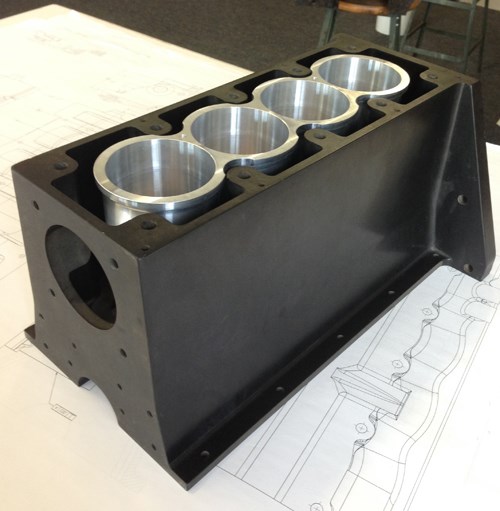

Composites Castings' all-composite Polimotor 2 engine block uses AGY S-2 glass.

In another development, AGY’s its S-glass has been selected by Composite Castings (Palm Beach, Florida) for its all-composite Polimotor 2 automotive engine. The block of the engine was on display at AGY’s booth. It will use AGY S-2 glass fibers to increase mechanical performance with a 90-lb/41-kg reduction in weight compared to a similar metallic engine block. The prototype engine will be installed in a racecar over the summer that will compete at the Petit Le Mans, Road Atlanta course later this year. Early blocks were built using carbon fiber, but currently and for the next generation glass fiber will be used. AGY and other developmental partners are working with Composite Castings to develop the Polimotor for an unidentified auto manufacturer that is considering this composite engine technology for a commercial application.

Airtech vacuum bagging products

Airtech featured its extensive vacuum bagging and composite tooling materials for prepreg/autoclave, resin infusion and wet layup processes (up to 426°C). Airtech covers markets from automotive and aerospace to marine, wind, printed circuit boards and solar energy. Airtech’s booth featured its latest Airdraw 2, said to be the widest compaction film, up to 3,98m wide, with an embossed pattern that provides a network of air passageways and eliminates the need for a separate layer of breather. Also, the company introduced its new Stretchflow 2000 high stretchable nylon breather. Its knitted construction is said to accommodate a wide variety of size applications and complex shapes, while eliminating wrinkles.

Aliancys (formerly DSM) comes out

Formerly DSM Composite Resins, now a spin-off from DSM, Aliancys is a leading provider in quality resins for composite applications; especially polyesters, vinyl esters, and urethane hybrid chemistries. Primary innovations mentioned were resins for use with carbon fiber (pultrusion, SMC, RTM), styrene-free or reduced-styrene resins and resins designed for improved wind fatigue performance in carbon composite wind blades.

Other areas of focus include vinyl ester for composite food containers, and piping for drinking water. For making these resins, Aliancys applies good manufacturing practices (GMP) to ensure the right measures are taken to avoid contamination of food/water products through resin ingredients. The company has been reformulating some resins to meet eligibility requirements for the European Commission Positive List of products for healthier, safer citizens of Europe.

Aliancys is also focused on resins for pultrusion, and is working with several companies on resins for pultruding carbon and fiberglass rods and cables for the offshore oil/gas industry. Another area of increasing interest is in low profile additives for reduced shrinkage of composite shapes.

Siemens F1 presence

Siemens PLM has made exhibition of a Formula 1 racer an annual tradition at the JEC show, and 2016 was no exception. The Renault team relies heavily on Siemens' Fibersim software to help it optimize vehicle design. Design and manufacturing cycles for F1 are notoriously short and intense, but the resulting vehicle must be precisely engineered and, above all, safe.

Berry Plastics and specialty veils

Berry Plastics (Evansville, IN, US) produces specialty material for composites products. Focusing on the science behind composites, its main products include its MATLINE cores, flexible bulky nonwovens that reduce mass and resin content; REEMAY polyethylene terephthalate (PET) surface veils for improving surface characteristics of thermoset composite products; thermoplastic veils for improving surface quality in thermoplastic composite products; and REEMAY PET adhesive carriers, which offer thermally stable isotropic properties for application of high performance adhesives.

L&L Products and breakthrough film adhesive for BMW

Activity was high at the stand of L&L Products (Romeo, MI, US), thanks to the huge interest generated by the BMW 7-series body-in-white on display at the SGL stand nearby. L&L supplies the toughened epoxy adhesive used to bond a carbon fiber/epoxy structural element to the 7-Series’ B-pillar. The innovative product, developed exclusively for BMW, consists of an epoxy film with an embedded glass fiber veil that is preformed with the carbon composite plies; the veil not only provides galvanic isolation between the carbon part and the B-pillar’s metal substrate, but also prevents squeeze-out of the adhesive during part forming, thus protecting the forming tool. The adhesive had to pass numerous stringent tests to qualify for the automotive program, says Didier Trau, project manager of advanced development at the company’s Molsheim, France facility, including curing within the 2-minute part cycle (the product can be adapted to 1-minutes cycles) as well as standing up to the e-coat temperature and final assembly.

Crea Fibres for technical applications

Créa Fibres (Tourcoing, France), while not an exhibitor, demonstrated to CW its range of technical slivers, felts, yarns, tapes, braids and fabrics that have application in the composites industry. The company’s stretch-broken, 12-micron stainless steel fibers are twisted and spun to form yarns, which technical sales engineer Régis Boulanger explained are used by customers to impart electrical conductivity to hybrid textiles for antistatic and electromagnetic shielding applications. With excellent high-temperature resistance, the steel yarns are used alone or blended with other thermostable fibers for demanding applications, including satellite structure. Aramid, polyester and polypropylene fibers are also available.

Chem-Trend and water-based mold release

Chem-Trend (Howell, MI, US) is focusing on further developments in its water-based mold release technology for environmental protection. While release agents are responsible for minor emissions generated in composites molding, European regulations are becoming increasingly strict and, of equal importance, parts are getting bigger: for example, in wind energy conversion composite blades and for airframe wing sections and other aircraft parts. The combination of stricter regulations and larger parts makes any reduction in emissions an important factor in composite production.

Solvay foam core cooperation with 3A Composites

This sample part, in the Cytec Solvay stand, features Solvay's new TegraCore PPSU foam core with carbon fiber/PPSU prepreg. Developed in collaboration with 3A Composites (Sins, Switzerland). The core has been qualified by Airbus and is flying on the A350 XWB, although Solvay would not name the application. Armin Klesing, head of aerospace materials business, says it's suitable for interior or exterior use, meet FAR requirements, resists liquids, and resists damage more effectively than Nomex honeycomb. This particular part was vacuum bagged and thermoformed to shape, testifying to what Solvay says is the material's ease of handling and processing.

Covestro polyurethanes

Covestro (Leverkusen, Germany) featured developments in polyurethanes and polycarbonates, presenting “materials and processing solutions that support function integration and offer potential for cutting costs.” Power generation from renewable sources is a key focus of Covestro. For example, the company has developed an innovative technology for manufacturing wind turbine rotor blades by vacuum infusion using its polyurethane resin with fiberglass fabric from Saertex (Saerbeck, Germany). Renewable energy was also the motivation behind its partnership with Solar Impulse and Covestro’s design and construction of a special rigid polyurethane foam for the cockpit of the Solar Impulse 2 (Si2), currently attempting the first round-the-world flight of a solar-powered aircraft. The company has also developed a new polyurethane matrix from its Baydur line; its role in a carbon fiber composite is to promote high-level automotive occupant safety.

Carbon fiber wheels

Kingfa Advanced Composites, based in Guangzhou, China, displayed its Stren carbon fiber wheels, available with aluminum spokes.

Electroimpact equipment in 777X wing manufacture

Electroimpact (Mukliteo, WA, US) announced it has received a new contract from Boeing for Automated Fiber Placement (AFP) systems to layup the wing spars and wing skins for Boeing’s next generation 777, the 777X, touted by Boeing as the “largest and most efficient twin-engine jet in the world, with 12% lower fuel consumption and 10% lower operating costs than the competition.” Michael Assadi, engineering manager for Electroimpact says these are the newest general, high-performance AFP machines on the market, with a laydown rate for carbon/epoxy tape of 200 lb/hour. The 6-axis machines are now being installed at Boeing’s Everett facility and production is scheduled to start in July 2016.

Fives Group ATL and AFP

Fives Group (Capdenac Gare, France; Hebron, KY, US) designs and manufactures machines, process equipment and production lines for key industries and has acquired and incorporated several machinery manufacturers into its line of metal cutting and composites manufacturing. One of the machine systems featured in its booth was Forest-Line’s two-stage tape laying system, ACCESS/ATLAS, according to Robert Harper, director, technical sales, proposals and application engineering. First designed and built by the former Goldsworthy Engineering in the 1980s, updated versions have continued to be built by Fives for major airframe OEMs and used in construction of composite primary structure on new aircraft.

Patrick Rousseau, key account manager for Fives, was on hand at JEC to share this history. Rousseau was also on hand at Goldsworthy Engineering, as a representative of Forest Line, in the days the prototype ACCESS ATLAS system was being built, as was this writer, giving us a chance to reminisce.

Car hood concept — one of many

This demonstrator hood, on display in the Auto Planet pavilion, was developed by Delta Motorsport, Jaguar Land Rover, KS Composites and SHD Composite Materials. It combines carbon fiber and flax with epoxy. The inner and outer sections are fabricated separately (in autoclave) and then bonded together.

General Plastics polyurethane-based foam

General Plastics (Tacoma, WA, US) featured its polyurethane-based Last-a-Foam FR-3800 FST foam — qualified for aerospace fire/smoke/toxicity and heat release requirements. On the market for six months, the foam is said to be a cost-effective replacement for honeycomb in aircraft panels or dividers that offers comparative strength values. The company says it is unique in that there are a limited number of materials that pass heat release and FST requirements for aerospace. “This is the first cost effective material that meets FST/OSU 65/65 (Ohio State University heat release standards),” they say. Available at three to 40 pound/ft3 (48 to 640 kg/m3) density, and sheet thickness up to 24 inches, it can be laminated with fiberglass.

The company also showcased a fiberglass/phenolic aircraft application with closed cell honeycomb. At 3 lb/ft3 vs honeycomb at 1.5 lb/ft3, the material has a weight penalty but the company believes this is well offset by the cost savings of the manufacturing process.

Radius Engineering and A320 wing flap

Radius Engineering (Salt Lake City, UT, US) featured its Airbus A320 wing flap, produced at its plant in Salt Lake, Utah, and by its partner Coexpair in Namur, Belgium, manufactured by RTM and SQRTM. The SQ is for Same Qualified, which means it is an out of autoclave process that produces the same quality as an autoclaved part. (See Radius’s SQRTM helicopter roof development covered by CW in August 2010). Finite element analysis was by Samcef from Siemens (Munich, Germany) and Nastran from MSC (Newport Beach, Calif.). Designers use Catia V5 modeling software from Dassault Systemes (Cedex, France) for composite part and tool design.

Award-winning thermoplastic truck firewall

This structural thermoplastic truck firewall was on exhibition at JEC 2015 on the Solvay stand, and returned this year as a JEC Innovation Award-winner. It uses compression-molded organosheet (PA6/glass fiber, 50% loading) combined with a rib structure that uses PA6/glass fiber at 30% loading. Weight savings was 25% compared to the metallic predecessor. Component reduction was 50%.

Reichhold gelcoat for transportation

Reichhold (Sandefjord, Norway; Research Triangle Park, NC, US) featured its new fire retardant gelcoat for transportation applications, especially for rail cars. An intumescent system, Norpol SVX gelcoat expands and protects when the part starts to burn. Used with Reichhold’s Dion 7721 fire resistant unsaturated and halogen-free polyester resin, reinforced with fiberglass chopped strand mat, it meets strict fire/smoke/toxicity regulations such as EN 45545-2:2013, which is now being implemented for all new rail contracts.

Reichhold also introduced Advalite, a monomer-free, flexible vinyl hybrid resin specifically designed to produce low tack, zero VOC hot melt prepregs. Advalite does not require refrigerated storage and is said to achieve high performance with compatible carbon fiber. Advalite vinyl hybrid liquid resins are low viscosity resins designed for high end structural and impact resistant composite applications formulated for use in pultrusion, filament winding, wet molding and infusion composite manufacturing processes. Available in no- or low-monomer content. Is said to produce very low emissions and maintain mechanical properties at elevated operating temperatures.

Riba Composites and the carbon fiber wheel

Despite the application of carbon fiber in more production vehicles over the last few years, carbon fiber wheels have remained few and far between, and those that have been developed are options on high-end sports cars only. The most notable carbon fiber wheel on the market is the one-piece CR-9, a nine-spoke wheel fabricated and sold (for about $3,000/wheel) by Carbon Revolution (Warun Ponds, Australia). The wheels were developed for the new Ford GT350R, but are also available aftermarket.

Andrea Bedeschi, general manager at Riba Composites (Faenza, Italy), told CW that his company has begun a serious and collaborative effort to develop its own line of carbon fiber wheels, targeting volumes of 20,000-40,000 year at a price point of about $1,200/wheel (if not lower). To do this, Riba is working with Fraunhofer ICT (preforming R&D), ALPEX Technologies (tooling), Bologna Univeristy (materials), Cannon (HP-RTM equipment) and TüV Rhineland Group (testing). Bedeschi says Riba's early work focused on development of a five-spoke wheel using carbon fiber prepreg, but production volume requirements forced a shift to HP-RTM using matched metal tools. The company is also being challenged by the five-spoke design in general, which, traditionally, has struggled to pass impact tests. Riba's design, says Bedeschi, is still in flux.

Riba hopes to have a prototype wheel on display at JEC World 2017, followed by commercialization in 2018.

Textechno and fiber testing technologies

One of the JEC Innovation Award winners was textile testing specialist Toho Tenax America Inc. (Mönchengladbach, Germany), which featured a wide array of highly specialized, highly automated, highly precise fiber testing systems. Dr. Ulrich Mörschel, managing director, highlighted systems for measuring fiber diameter and length, drapability and tensile strength. The company won the award, however, for its Fimabond product, which assesses the quality of adhesion between a resin and a fiber. The system uses an automated process to embed a fiber into any kind of resin matrix. It then does a pull-out test to characterize interfacial shear strength and modulus. The system also determines fiber circumference and other fiber properties.

McClean Anderson and new winding software

McClean Anderson LLC (Schofield, WI, US) announced at the show that is has released version 2.0 of its SimWind software produc. The updated pattern development software, now available for download, features an enhanced graphical interface, pattern simulation improvements, robust motion editing, increased stability and performance, and multi-platform support. SimWind 2.0 supports a wide range of data formats to export and import mandrel and motion data, giving the ability to create programs for complicated axis-symmetric structures. Extensive technical support is available from the company.

Owens Corning and new products for piping

Owens Corning Composite Solutions Business (Toledo, OH, US) introduced two new glass products for the piping market, Pipestrand M6000 and Pipestrand S2300/2500. According to Bryan Minges, global product manager for OC’s composite solutions business, the company worked for a year with customers, benchmarking fiberglass products for piping, and testing the products both in-house and in outside laboratories. Testing included a full suite of mechanical properties including burst strength and axial tensile performance, says Minges: “Piping, along with wind and long fiber reinforced thermoplastic (LFRT), is a new focus area for us, and we have consolidated all of the many products we offered previously, to make it simpler for our customers.” Pipestrand M6000 is a multi-end roving Advantex glass fiber with a sizing system designed for polyester and vinyl ester resins, for filament-wound, low-pressure water pipes and tanks (a single-end roving version is also available). Pipestrand S2300/2500 are single-end rovings with a sizing designed for epoxies (both amine and anhydride curing systems), for high-pressure pipe applications in long-service-life situations in the oil and gas industry or industrial plants. Minges says that the company researched new silane-based sizing/coupling agents, which give better interfacial bonding and strength: “These products deliver measurably higher mechanical properties, which means the pipes can be used in more demanding applications, or they can deliver the same performance, but with less material, for lighter weight.” Another big advantage is lower fuzz issues, due to the new sizings as well as improvements to the glass itself, which results in lower resin consumption and higher productivity, says Minges.

Sicomin success with bioresins

Sicomin Epoxy Systems (Châteauneuf les Martigues, France) reported that it continues to expand production of its Greenpoxy 56 bio-based epoxy resin, with over 50% bio content, and will now be stocking product in the US state of New Jersey for North American customers, CW learned from Marc Denjean, the company’s export manager. Greenpoxy is available in a range of bio content, and can be used in a range of processes from hand layup to high-pressure resin transfer molding. According to Denjean, Greenpoxy now comprises the major part of Sicomin’s production, due to strong customer demand: “Greenpoxy has the highest bio-based content in the industry, and it delivers high optical clarity and the same mechanical performance as a traditional petrochemical-based epoxy, at virtually the same price.” Also featured were Sicomin’s fire retardant epoxies, including a new system, SR 1125, which is an advanced self-extinguishing epoxy with a viscosity compatible with infusion processing. It is targeted to large parts in architectural, civil engineering, rail applications, in load-bearing structure where fire resistance is key.

SCIGRIP debuts MMA white paper

SCIGRIP Smarter Adhesive Solutions (Durham, NC, US) highlighted its SG600 adhesive designed for bonding of plastics, specifically low surface energy (LSE) materials such as dicyclopentadiene (DCPD), ABS and PVC. Such materials tend to oxidize after production, and typical bonding requires extensive sanding and surface preparation to remove the oxidation; two-component, 10:1 mix ratio SG600 needs minimal surface preparation to bond well, and controls read-through, for fast automotive assembly. The company also debuted a new white paper entitled “An Introduction to MMA Structural Adhesives.” The white paper is available on the CW Web site: http://www.compositesworld.com/cdn/cms/cw_whitepaper_scigrip_mma_intro.pdf.

Santex Rimar Group announces thermoplastic prepregging

Prepregging system manufacturer CAVITEC, a brand within the Santex AG (Trissino, Italy), is a well-known supplier of thermoset prepreg manufacturing equipment. At the show, Rolf Troendle, director of the technical textiles division of Santex Rimar, told CW that the company is moving into thermoplastic prepregging as well. A pilot line is already operational in Switzerland producing polyamide tapes, and equipment for higher-temperature PEEK and PPS tapes is under development; exact processing methods for making the tapes are proprietary. The thermoplastic lines have to be capable of processing a range of resins, and both unidirectional and fabric styles, says Troendle. “We had many customer requests for thermoplastic processing equipment, which is being driven by the challenges in automotive part processing.” He notes that CAVITEC is also involved in several European composites projects, including one involving recycled fibers. With regard to its thermoset prepreg systems, Troendle adds that improvements are being made in the areas of handling systems, including full automation, more ergonomic designs, and even non-stop, 24/7 systems.

Scott Bader and new adhesives

Scott Bader Company Ltd. (Northamptonshire, UK) promoted several products, including Crestabond PP-04, a new 1:1 adhesive with a working time of four minutes, developed for bonding polypropylene (PP), polyethylene (PE) and other low surface energy thermoplastics; plus an even faster, sub- three minute curing, new version of structural adhesive Crestabond, M1-02, which requires no primer for high volume assembly of metal, plastic and composite components. Crestabond M1-02 is now the fastest curing 10:1 ratio grade option available, developed for higher volume assembly of smaller parts that must be ready to handle in under three minutes for cost effective productivity. The company displayed a prototype for a new British sports car, a two-seater convertible with a very rigid, lightweight carbon fiber (CFRP) composite passenger cell frame fabricated by Axon Automotive (a subsidiary of Far-UK Ltd), using its internationally patented AxontexTM structural beam technology,

which specifies Scott Bader’s Crestapol1250LV infusion resin. According to Axon Automotive the passenger cell prototype frame design is 43% stiffer and is 15% lighter (by mass) than an equivalent lightweight steel frame.

Coats and new composite material

Coats (Uxbridge, Middlesex, UK), the world’s largest manufacturer of sewing thread and other products, used the show to introduce Synergex, its commingled carbon/thermoplastic fiber material. The hybrid fiber, developed at the company’s site in Sevier, NC, US, is spread and commingled with a number of thermoplastic resins, with or without twist, for manufacture of various composite parts. On display was a flat, embroidered carbon/nylon commingled preform, made using tailored fiber placement (TFP) with Synergex fiber stitched onto a carrier film. The preform is molded by a partner firm, car maker Elemental Group Ltd. (Hambledon, Hampshire, UK), to produce a complex wheel arch fender part demonstrator in a sub-1-minute process. University of Stuttgart is a partner in the preforming process.

3B Binani product for automotive molding

3B – the fibreglass company (Battice, Belgium) offered a new glass product, DS 1125-10N, made with E-CR corrosion-resistant glass and composed of individual glass filaments of low micron diameter, explained 3B’s automotive market manager Eric Debondue. The new glass, which comes in a granulated shape, is designed to fit a broad range of polyamides including PA6, PA6.6, PA6.10, as well as copolymers PA6/66 and semi-aromatic polyamides, and exhibits superior dispersion for good part cosmetics.1125-10N is designed for smooth compounding with excellent feeding properties and it generates extremely low fuzz-and-fly, hence reducing cleaning and maintenance downtime. As a consequence of its tailored strand’s integrity, it can be used in high-throughput compounding lines fed by pneumatic conveying. DS 1125-10N is also neutral in color, meaning it can be used in any natural grade compounds without impacting final part color, and is also compatible with flame retardants and impact modifier additives. It also show a very good resistance to a wide spectrum of mold-release agents including calcium stearate. The product sizing does not interfere adversely with polymer viscosity, which makes it ideal for polyamide compounds of high fluidity, enhancing productivity in injection molding, adds Debondue: “The combination of this well-balanced fiber repartition with an efficient adhesion of sizing to polyamides, translates into excellent dry-as-molded mechanical properties of the final parts in both static and impact properties.”

Related Content

NREL develops biomass-derived resin PECAN for wind blades

Demonstration and findings validate PECAN as a method for developing long blades that perform well with composites, outperform some resins and enable chemical recycling.

Read MoreEuropean boatbuilders lead quest to build recyclable composite boats

Marine industry constituents are looking to take composite use one step further with the production of tough and recyclable recreational boats. Some are using new infusible thermoplastic resins.

Read MoreBiomaterials make strides toward composites sustainability

A compilation of trends in development or application of natural fibers, bio-based resins and more showcases industry players, educational institutes and global projects.

Read MoreDuplicor biocomposite cladding aids redevelopment of ABN AMRO office building in Amsterdam

Chosen for low CO2 footprint, RC value >9, fire resistance, light weight and high strength, Duplicor façade structures are key to two-story extension.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More