(Top left, clockwise) Thermoset composites, CEO Kjelt van Rijswijk, thermoplastic composite welding cell and KVE group photo in The Hague. Source | KVE Composites

CW has written quite a lot about KVE Composites (The Hague, Netherlands) and its parent company Daher (Orly, France). I also interviewed Kjelt van Rijswijk — KVE’s new CEO — in his previous position at SAM XL (Delft, Netherlands). This blog, however, reweaves these three threads to discuss KVE and Daher with van Rijswijk as CEO. It is based on my interview with him and Maarten Bach, business manager for thermoplastics at KVE, to better understand the company’s underreported past as a manufacturer of thermoset composite parts and its vision for future thermoplastic composites with Daher.

CW: You were previously CEO of the SAM XL composites automated manufacturing lab. Why become CEO of KVE and how is this a good fit?

Van Rijswijk: My father was a carpenter. So, I grew up with making stuff. And then, also at TU Delft in the aerospace department, I continued my passion for making stuff, but from more advanced materials. I did my internship in South Africa, at Stellenbosch University (Cape Town), working on structural analysis for small SUNSAT satellites made by the South African National Space Agency (SANSA).

I liked South Africa, so I returned there after completing my PhD in Delft, and worked for Aerosud in Pretoria making A400M cargo liners. This being a military aircraft, the cargo liner needed to be resilient and abuse-resistant. So, Aerosud decided to make it out of glass fiber-reinforced thermoplastics. They needed somebody to head up the program, and I stayed for 11 years. I built a team that implemented that in production and then moved to starting production of A350 frame clips. Again, my focus was on developing products and making them, including developing the press forming machines to build those parts.

And even before, throughout my Masters and Doctorate degrees, I’ve always been making the machines used to make composite parts. I don’t have a mechatronics background, but I’ve always needed to develop the manufacturing equipment. So, I learned from a production point of view and was involved from A to Z — procurement through production and final delivery.

As the new CEO of KVE Composite, Kjelt van Rijswijk’s background fits well — spanning composites groups in the Netherlands and South Africa, most recently as CEO of SAM XL, which completed the automated welding of the MFFD lower fuselage shell in the Clean Aviation STUNNING project. Source | SAM XL

After that, I wanted to boost the South African composites industry. So, we started a composites cluster in the Mandela Bay region with focus on supply chain development, collaborative innovation and skills development. I did this for 5 years after which I moved back to the Netherlands. That was when I began working with what became SAM XL — a combination of university lab, industry lab and a hub for developing mechatronics, programming and machines as well as designing and producing composites. TU Delft offered me the challenge to build an organization and establish the facility, so that’s what I did. We built a legal entity and equipped it with a massive gantry robot, which then led the automated welding of the MFFD lower fuselage within the Clean Aviation STUNNING project. The process we developed and demonstrated with the industry partners are really at industrial scale. At that point, I was ready to go back into industry because a big part of SAM XL is still research-oriented. And that’s when the opportunity at KVE arose.

CW: What is your role at KVE?

KVE Composites produces thermoset composite radomes, parts for machines, brackets, components for machine equipment and special products for the defense industry, as well as rotor blades for aircraft — it was a partner in the Smart Rotors project to develop ultra-efficient propeller and rotor blades for hybrid/electric aircraft and drones. Source | KVE Composites

Van Rijswijk: Well, first of all, the company is much more than induction welding, which is the only part most people know about. That is a prominent focus area, but there is much more. KVE produces thermoset composite parts such as radomes and rotor blades. It also has a second location in Maastricht that focuses on composite repair. Both divisions are growing yet are focused on two different markets and two different value propositions. This is why the previous owner and managing director, Harm van Engelen, decided that both facilities needed to be run by a dedicated person. So, he leads the repair operations in Maastricht, and I am leading the KVE team that makes parts in The Hague.

Also, Daher acquired KVE in 2019, which has provided further backing and expertise to make growth possible, especially in thermoplastic composites. So, we are also developing and maturing the processes in thermoplastic composites and doing a lot of testing work together with Daher, and we are learning from each other.

Today, a substantial part of revenue already comes from parts manufacturing — we’ve got all the equipment and know-how to produce parts as well as tooling at KVE in The Hague — and revenue from welding thermoplastic composites generated together with Daher will steadily grow going forward. That’s our vision.

CW: And how will that work with Daher?

Van Rijswijk: At JEC 2024 we exhibited together with Daher and highlighted a welded thermoplastic composite torsion box for a horizontal tail plane (HTP) based on their TBM aircraft. KVE had previously welded a subscale torsion box, but this one was full-scale.

KVE Composites robotic welding cell with thermoplastic composite torsion box. Source | KVE Composites

Elementary parts are manufactured by Daher in Nantes and the assembly process is executed by KVE in The Hague. Besides performing the welding, KVE also offers tooling and equipment for other companies, enabling our customers to assemble parts in their facilities.

Bach: Although induction welded parts have been flying for years, we continue to mature the technology more and more. And it means that widespread commercial implementation is closer and closer. But as you approach this point, your responsibility as a company increases as well. Together with Daher, we are a much stronger unit to share this responsibility and give confidence to OEMs and Tier suppliers so they can also be developing programs using this technology. And they would do this because welding reduces weight and minimizes the need for drilling and mechanical fastening, which greatly reduces production time and cost. But this also requires that you make parts designed for welding and that’s also technology we have been developing together with Daher.

Van Rijswijk: Daher is focusing on the thermoplastic part forming. For these large assemblies, you need significant floor space and diverse capabilities in terms of press forming, etc. You need all of this to support the next generation single-aisle aircraft programs, while we supply the welding technology and develop the applications with them.

CW: How much is KVE involved in certification?

Van Rijswijk: Obviously, Daher already has a long history in certification, both as a parts manufacturer and as an aircraft OEM. From our side, we make components, and they are all certified, but either as non-primary structures or by the customers as part of their assemblies. For these welded structures, it’s a bit different. That’s where our work together with Daher is helping with the development of welding for certification, but also as we advance technologies for rotor blades, because they are a critical structure for unmanned and advanced mobility aircraft, which are huge markets that are a good fit for us.

KVE Composites and Daher demonstrated a welded subscale in 2023 (top) and exhibited a full-scale welded thermoplastic composite torsion box at JEC Word 2024 (bottom). Source | “Thermoplastic composite welding advances” and CW, JEC 2024.

Bach: I would add one more thing for the welding. The full-scale HTP torsion box is completely designed according to the certification approach developed by Daher. It is a TRL 5/6 demonstrator to prove all the steps of the certification and this will allow us to produce a part in the same way. And that’s the philosophy we have together with Daher.

Van Rijswijk: Daher makes the TBM aircraft, and therefore has design authority for its certification. This full-scale torsion box is a thermoplastic composite representation of their HTP torsion box for the TBM. So, you have all the real requirements included. Many demonstrators that you see at exhibitions are not designed to fly or operate in service. But the part we have produced with Daher includes the real engineering loads, manufacturing and service considerations.

CW: So this full-scale TPC torsion box is a flying part?

Van Rijswijk: The next step is to have a flying part. Daher is talking about this with EASA, and the rest of the industry are also having those discussions with the FAA and EASA, as well as with Boeing and Airbus.

CW: Let’s go back to rotor blades. How do you see that market and where would KVE be able to play?

Van Rijswijk: A rotor blade is a flight-critical part. And that means you need access to unique expertise. As a small company in the Netherlands, we cannot have all of this expertise in-house, full-time. Therefore, we access expertise from Daher. We see the drive toward sustainable aviation and electric-powered flight, where you typically need multiple sets of rotor blades. And even though there is redundancy in the rotors, you still have to prove everything according to aerospace industry standards and regulations.

We are also very good at short cycle prototyping, which is key, as most of these eVTOL (electric vertical takeoff and landing) aircraft are still very much prototypes themselves. And you need to be able to prototype but still be cognizant of all the aerospace requirements. And that is something that we are good at. That’s how we can support as a partner, because these eVTOL projects need to develop and be certified and then scale up at the right time.

KVE Composites is working with multiple unmanned and advanced mobility aircraft platforms. High Eye is a Netherlands company that has developed the Airbox remotely piloted aircraft platform. Source | High Eye YouTube video

CW: Are you talking to the advanced air mobility community, and can you name any platforms you’re supporting?

Van Rijswijk: We are already producing rotor blades that are flying for multiple platforms. We had two on display at JEC World 2024. We have to be careful what we disclose, but these are all thermoset composite parts made with a one-shot RTM (resin transfer molding) process using woven and UD (unidirectional) reinforcements and a foam core inside. The customer designs the aerodynamics, but we do the structural engineering and combine that with the manufacturing engineering.

An induction-welded thermoplastic composite spar to skin (top) and standardized L-coupon for generating certification test data (bottom). Source | KVE Composites

But that also shows the unique DNA of KVE Composites — that we are helping to develop this industry. For example, all these eVTOL platforms have special requirements regarding payload, speed and range which then brings them to select a specific engine and battery package. And for that you need a specific rotor design. And you need somebody that can quickly design, prototype and test the rotor blades as well as help in certification and then also be capable to ramp up production. KVE offers a unique package of those capabilities, including design and knowledge of thermoset and thermoplastic composite materials as well as production methods. That is what we do.

CW: Could you make these rotor blades from thermoplastic composites?

Van Rijswijk: In the future, yes. However, with this size, we still believe that one-shot RTM is the best fit. If the blades get bigger, you will need to build ribs and spars. And then we can see thermoplastic composites would work well for stamping the parts and then using our welding process for assembly. So that’s something for the future. But with the current size and rates, we know and use a certain system where we can produce at the cost and volumes required. We also include quite a bit of automation in the process, which is highly scalable.

CW: So, then Kjelt, your background really fits perfectly with where KVE Composites is headed.

Van Rijswijk: Absolutely. We’re looking at these different parts and market opportunities and how to build the necessary processes and machines. And that is what I’ve always done.

Bach: But KVE Composites is also still a key partner in R&D projects. For example, the Netherlands growth fund launched a multi-million dollar, 8-year program last December called “Aerospace in Transition” to support Dutch industry in sustainable aviation. This is being led by Arnt Offringa at Fokker Technologies and also includes, among others, DTC (owned by Collins Aerospace), Toray Advanced Composites, Airborne, the TPRC and KVE Composites. The program will make larger, more complex thermoplastic composite structures. So, we are on the assembly side of that development.

The program is split into two parts: the first 4 years and the second 4 years. There will probably be some demonstrators, but also just some market vectors to allow companies to mature their technologies. For example, some companies want to mature materials while others are looking at equipment and processes and others provide sensors and process control technology. There are multiple work packages for all of the partners to participate and mature their offerings to achieve sustainable aviation.

Van Rijswijk: I’ve now been in KVE Composites for a year. And we’re setting up the company for expanding serial production of parts, not just one prototype here and there. We don’t make thousands of parts per month, nor do we only do prototypes, but we are ramping up. And we have a unique combination with Daher, which is a family-owned company with strategic thinking. We have an amazing team and I’m excited to be a part of what we’re achieving.

Related Content

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

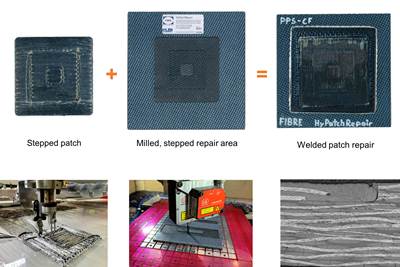

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreWelding thermoplastic composites

Multiple methods advance toward faster robotic welds using new technology for increased volumes and larger aerostructures.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More