Articles

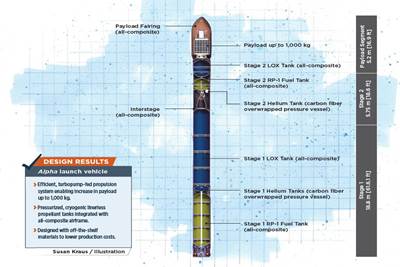

The Alpha launch vehicle: Designing performance in, cost out

Firefly Aerospace’s Alpha 2.0 launch vehicle, designed to deliver satellites into low Earth orbit, gets a composites makeover in pursuit of larger payload capacity and more cost-effective performance.

Read MoreBridging the gap between CFRP and CMC

Novel composites offer performance up to 1000°C with faster processing.

Read MoreAutomated aerocomposites production: Liquid molding or welded thermoplastic?

Two materials and process approaches are demonstrated for CFRP bulkhead production.

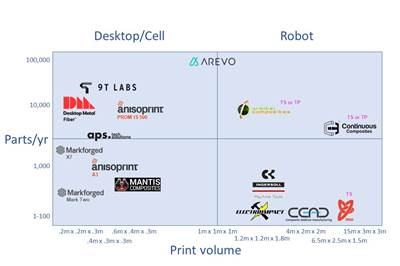

Read More3D printing with continuous fiber: A landscape

Growth continues in suppliers, part size, production volume and markets.

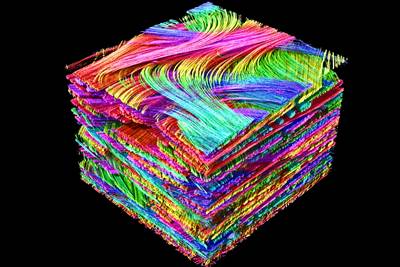

Read MoreApplying CT scan data analysis and visualization to composites

Imaging and analysis via computed tomography (CT) has potential for certifiable safety and business sustainability and could be key for interior inspections of composite parts. Part 1 of a two-part series.

Read MoreTU Munich gears up for full-scale Hyperloop demonstrator

As a new, university-directed research program, the Technical University of Munich Hyperloop team works to scale up its SpaceX competition-winning pod design.

Read MoreComposite aerostructures in the emerging urban air mobility market

In the not too distant future, point-to-point, limited-distance, piloted and autonomous air travel for people and cargo will be the norm. Composites will make it possible.

Read MoreIntroducing GreenPoxy bio-based epoxy resin systems

Sicomin Epoxy Systems offers an introduction to GreenPoxy - the company’s line of bio-based epoxies and gelcoats, available in industrial quantities for a wide range of manufacturing processes and market applications.

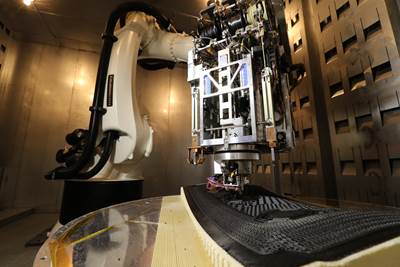

WatchCombining AFP with 3D printing for flexible parts production

Electroimpact creates a multifunctional manufacturing cell for complex, aero-quality continuous fiber composite parts.

WatchMold cleaners, primers, sealers and internal/external releases

AXEL Plastics reviews its line of mold cleaners, primers, sealers and internal and external mold releases designed for closed mold and pultrusion manufacturing processes.

WatchHow Digital Cutting Technology Reduces Costs and Improves Flexibility

Automated cutting of composites reinforcement and other technical textiles is faster, more accurate and can result in dramatic reductions in material waste and labor. Having the right software is the key to getting the best results.

WatchGraphene 101: Forms, properties and applications

Graphene-enhanced composites find new applications across end markets as the supply chain continues to mature.

Read More