Articles

C-WEAVE™ High Performance Carbon Fabric from the Chomarat Group

C-WEAVE is a bi-directional (0°/90°) warp and weft woven carbon fabric.

Read MoreImpact Delamination Reduction of Multiaxial Carbon Fiber Composites Using Interleaved “Micromesh™” Polyamide Veils

Learn about how excessive damage due to impact events can severely limit the use of carbon fiber composites in high performance applications.

Read MoreIncreasing Shear and Torsional Properties with Carbon Fiber Double Bias Fabrics

While stitch-bonded carbon fabrics are used successfully as direct replacements for traditional 0°/90° woven versions, this article will concentrate on their use in increasing in-plane off-axis (in this case ±45°) laminate properties.

Read MoreROVICORE™ – the leading Closed Mold Solution

ROVICORE is a reinforcement made with a synthetic non-woven core and chopped glass fibers mechanically stitched together.

Read MoreInfusion success starts with “R2O”

Vectorply’s “Road to Optimization” crucial in Cruisers Yachts 390 Express Coupe infusion

Read MoreVectorFusion™ Reinforcements Utilized with CCP Composites’ OptiPLUS® Resin for Infused Tooling Applications

With recent advances in CCP Composites’ OptiPLUS® infusion grade, low viscosity, shrink-controlled polyester resin, and the proper selection of Vectorply reinforcements, mold building can be greatly reduced from weeks to only a day or two.

Read MoreC-PLY™ – a Design & Manufacturing Game Changer

C-PLY is a leading edge carbon NCF reinforcement with structural design benefits, premium surface quality and overall parts cost savings.

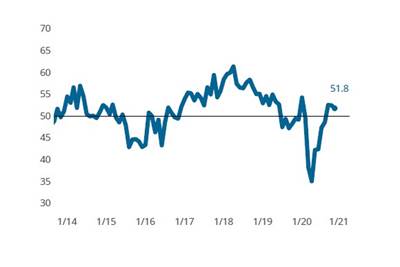

WatchComposites activity expands for third straight month

Production may struggle under slowing new orders and supply chain challenges.

Read MoreWhat is the role of composites in electric vehicles?

Governments and automakers are sending clear signals that electric vehicles are the future. Lightweighting EVs with composites seems obvious, but Dale Brosius says there are more opportunities not to be missed.

Read MoreFlexible carbon fiber plates enable high-performance footwear

Carbitex’s flexible carbon fiber/thermoplastic composite plates use creative engineering to eliminate design compromises in athletic footwear.

WatchBespoke process produces composite brake pedal every minute

Three composite materials are used to create structural composite member that meets demanding mechanical requirements.

Read MoreThermoplastic composite structure replaces metals on safety-critical brake pedals

First all-composite brake pedals developed by Boge Rubber & Plastics Group are lighter, stiffer, stronger and offer improved driving haptics.

Read More