Managing weight in emergency medical transport

Repetitive strain risk for first responders sends emergency equipment provider back to the drawing board to develop more ergonomic cot.

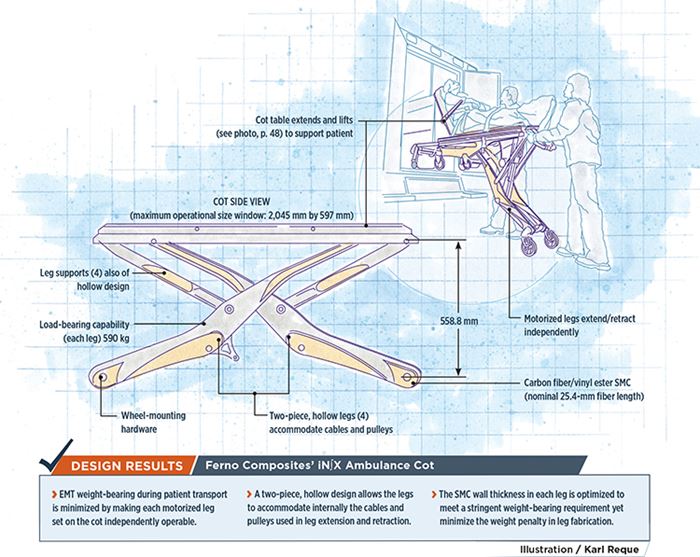

Design Results:

- EMT weight-bearing during patient transport is minimized by making each motorized leg set on the cot independently operable.

- A two-piece, hollow design allows the legs to accommodate internally the cables and pulleys used in leg extension and retraction.

- The SMC wall thickness in each leg is optimized to meet a stringent weight-bearing requirement yet minimize the weight penalty in leg fabrication.

Emergency medical technicians (EMTs) help people who are injured, severely ill or otherwise in need of emergency medical care, but also put themselves at risk via contact with diseased or potentially physically violent patients and exposure to injury associated with fire, explosive devices and traffic around vehicular accidents. Often overlooked, however, is back injury — well known in the profession, but little known outside of it — from repetitive lifting. EMTs bear the weight of both the patient and the stretcher (EMTs call it a cot) as the cot’s legs are retracted and the patient is moved into or out of an ambulance. For years, ambulance cots have featured manually operated, adjustable-height platforms, which enable EMTs to load patients onto cots at or near the elevation of floor, chair, bed or car seat on which they find them. When the patient is securely onboard, the cot is typically raised by the EMTs, manually, to full height and then wheeled to the ambulance. Critically, most of the energy of lifting and lowering is provided by the EMTs, as the cot’s legs are extended or collapsed.

Cot manufacturers eventually developed motorized units that take the manual labor out of leg extension and contraction. One motorized solution came from emergency medical services (EMS) equipment supplier Ferno (Wilmington, OH, US), but the company recognized that the weight management issue was more complex. Most conventional ambulance cots in the US feature aluminum tube construction and rely on two hinged, X-style support legs that are connected to its four wheels via a rectangular frame at the ends of the legs. Because they are interlocked, the four legs and all four wheels move in concert. Getting the patient up stairs, over curbs, across grassy ground, muddy roads or other variable terrain and around highway barriers to the ambulance in relative comfort and safety often requires that EMTs either partially or fully collapse the leg structure (motorized or not) and then bear the full weight of the patient to keep the cot stable. Years of repetitive weight-bearing can lead to chronic and debilitating back injury for an EMT, potentially cutting short his or her career.

Motorized, de-coupled legs

To solve the problem, Ferno began development work on what would become the iN∫X (pronounced “in-ex”), the world’s first EMS cot that features two pairs of motorized, independently operated legs. With the touch of a button, EMTs can raise or lower the front or back legs, as needed, and can keep one leg set deployed, in most cases, to help support patient weight as they negotiate stairs and other challenges.

Tim Wells, global emergency product manager at Ferno, says the company conceived of the iN∫X five years ago and then, through a series of focus groups, fine-tuned the design and confirmed that it was on the right track. Initial reaction to the design, Wells says, was overwhelmingly positive.

“EMTs and fire personnel looked at the iN∫X and could see right away the advantage,” says Wells. “This is a love-affair career, and EMTs have a real passion for what they do. Anything that allows them to do their job longer — as iN∫X does — is welcome.”

Lose weight, please

To make the iN∫X vision come to life, however, was another matter. Ferno project engineer Nick Valentino says Ferno’s experience was primarily with aluminum, but its engineers soon learned they’d have to change their thinking about not only leg design but materials as well. For the latter, Ferno turned to one of its suppliers, Citadel Plastics (now LyondellBassell). Called in early, during product development, Citadel representatives thought that the application was better suited for composites. Ferno’s experience with composites, however, was limited. “It was a new material for us, so we really had to put it through its paces,” Valentino says. “But we’re really just trying to keep weight down and this [composites] allowed a form and look that we wanted, and it created a part that got rid of a lot of other parts.” Citadel was retained to help guide design and engineering decisions.

The resulting leg design clearly offers aesthetic appeal (see photos at left), but Valentino says that once the decision to use composites had been made, function took precedence. The challenge, he says, is that all EMS cots must conform to some basic size and shape standards for ambulance compatibility. In addition, a cot must fit into standard-sized elevators and pass through standard-sized doorways. That meant Ferno was confined, with the iN∫X, to a fixed shape envelope of 597 mm wide and 2,045 mm long. Therefore, the independently operated legs, when both are closed, must fit within the shape envelope without interfering with each other, and allow sufficient room for mounting actuator motors between each set of legs without interfering with other cot functions.

“Leg geometry is more function than form,” Valentino notes. “They [the legs] must fit into an envelope that is typical of current designs. The legs must pass through each other, past actuator mounts and clear all bumpers.”

Roy Bendickson, product development engineer at Citadel, worked closely with Valentino and Ferno on leg design and helped guide material decisions to enhance composites manufacturability. He says Ferno’s first requirement was that each leg support up to 318 kg (the iN∫X is rated at 318 kg total). Second, each pair of legs must accommodate, through their length, the pulleys and wires required to raise and lower the legs.

The pulleys and wires are necessitated by another important function factor of iN∫X, as Valentino notes: “Wheel set distance is constant, regardless of cot height, so the legs must adjust their position under the cot to maintain wheel distance.” This gives the cot, and EMTs, a fixed and unchanging wheel position, which optimizes wheel function and maneuverability. To accomplish this, the tops of each set of legs must slide along the underside of the cot as the wheels are raised and lowered. (Leg operation is illustrated in a video available at the Ferno Web site: www.fernoems.com/inx.)

To meet all of these design and function requirements, Bendickson and Citadel recommended a two-piece hollow design for each leg. This would allow Ferno to place pulley hardware inside the legs during assembly and allow Citadel’s fabricators the ability to adjust wall thickness and other design elements more easily to meet load and weight requirements. That was a fortuitous decision. Late in the development process, Ferno decided that the weight limit on each leg should be almost doubled, to 590 kg, because designers wanted to ensure that any one leg, if absolutely necessary, would support more weight than the entire cot would ever bear. “We wanted to make sure the legs weren’t the weak link,” Valentino reports. This required, says Bendickson, some changes in sheet molding compound (SMC) charge placement, as well as part wall thickness increases, but was relatively easily done, given the two-piece leg concept.

Ultimately, the hollow design evolved to include, at the narrow end of the legs, an I-beam structure, which terminates at attachment points under the cot. The design also features four support arms for the legs, also made by Citadel and also of two-piece, hollow design.

Material, manufacturing options

Although the decision to go with a composite had been made early, the time had come to make specific material choices. Carbon fiber mat and unidirectional carbon fiber were evaluated, but Bendickson says carbon fiber SMC was selected because the legs “needed fiber that offered a variety of orientations for strength.” Supplied by Citadel’s Quantum Composites facility (Bay City, MI, US), the SMC, branded AMC 8590, features 12K tow (nominal 25.4 mm fiber length) in a vinyl ester resin matrix.

Citadel molds the leg halves in a compression-based process. It then machines holes into each half to accommodate support arm attachment points, wheel hardware, fasteners and thread-cutting screws and through-bolts, which are used to attach the leg halves together. Notably, leg halves are not adhesively bonded. Bendickson notes that hole-drilling is, therefore, particularly critical: “Close hole tolerance is needed for good holding power and service on the cot,” he says.

Already introduced into the EMS market via trade show demonstrations in 2014, the iN∫X, according to Wells, has been well received. Although the iN∫X sports a bigger price tag than the conventional cots on the market, customers reportedly see its value and understand the weight-management advantages the cot provides to EMTs. “We see it as a way to not only help EMTs do their job, but as a way to extend their careers as first responders,” says Wells. Ferno started shipping the first iN∫X units in January 2015.

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MorePultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More