Although expanding investments in South Carolina’s developing aerospace industry by The Boeing Co. (Chicago, IL, US) regularly capture regional and composites industry headlines, one of the state’s major educational institutions is more quietly, yet resolutely, making significant investments in aerocomposites workforce development. Composites technology is central to all four areas of focus listed in the mission statement of the University of South Carolina’s (USC’s) Ronald E. McNair Center for Aerospace Innovation and Research (Columbia, SC, US): aerospace education, research, outreach and economic growth. From course work as diverse as science, technology, engineering and mathematics (STEM) outreach to CATIA certification classes and core research into steered fiber laminate design, the McNair Center has set out to address the needs of the aerospace composites workforce at not only professional and collegiate levels, but also in K-12 educational institutions as well.

Named after South Carolina native and Challenger Space Shuttle astronaut Ronald McNair, the Center was founded in 2011 expressly in response to Boeing’s investment in South Carolina. USC previously had offered only an aerospace minor in its mechanical engineering program. Expansion of aerospace research and studies has occurred through the McNair Center endowment, funded by South Carolina philanthropists Darla Moore, Anita Zucker and Marva Small, all three of whom “are especially interested in workforce development,” notes center director Michel van Tooren. So far, McNair Center efforts have enabled the creation of two master’s degree programs: an MS in aerospace engineering and an ME in aerospace engineering.

A bachelor of science program in aerospace engineering is expected to open in fall 2018, van Tooren reports. It will offer 15 aerospace-intensive courses. Students will choose from three tracks in the program, one of which focuses on aeromechanical systems, where composites technology plays a predominant role. (The other tracks focus on aircraft electrical systems and air-related information technologies.) Next, the Center faculty hopes to modify and amend the existing program, which currently awards a Ph.D in mechanical engineering, to confer in future a Ph.D in mechanical and aerospace engineering.

Practical academics

Van Tooren came to McNair in 2013 after previously held positions in The Netherlands, involving academic research at Delft University of Technology (Delft) and industrial research at Fokker Aerostructures (Papendrecht). He and many of his fellow faculty members continue to conduct research that bridges academia and industry, and this emphasis at the Center has produced an atmosphere of practical, industry-focused exploration.

For example, Subramani “Mani” Sockalingam, a recent addition to the McNair faculty, worked in composite body armor product development before pursuing his Ph.D at the University of Delaware Center for Composite Materials (Newark, DE, US). His current research uses FEM and FEA tools to study the constituents and interfaces within composite materials. But even this fundamental research is conducted with an eye toward application. Sockalingam is lending his micro-scale expertise to a McNair team that is working on induction welding of composites. This interplay between basic and applications research advances both, Sockalingam believes, citing two projects that are studying joint reliability: An induction welding project emphasizes structural performance, while a complementary basic research project is studying joints from a molecular dynamics perspective.

The McNair Center’s 30+ faculty members represent mechanical, chemical, civil and electrical engineering disciplines. This multidisciplinary approach applied to composite aircraft structures means that the Center can cover the full spectrum of research: design, modeling, manufacturing and analysis. Ph.D candidate Jaspreet “Jessie” Pandher has found that multidisciplinary collaboration, plus access to shared equipment and exposure and connections to industry, are assets of Center-based research not often enjoyed by either traditional academic or industry-based research.

Although he initially entered USC to study mechanical engineering, Pandher “fell in love with aerospace” through an internship at the Center. He worked on an industry-sponsored UAV development project before beginning his Ph.D work. “It’s unique that we get to do actual industry projects that are going to be used by the industry sponsor,” he says. Within the Center, he adds, “Everyone is open to help out; you’re not secluded in one group.”

Industrial collaboration and equipment

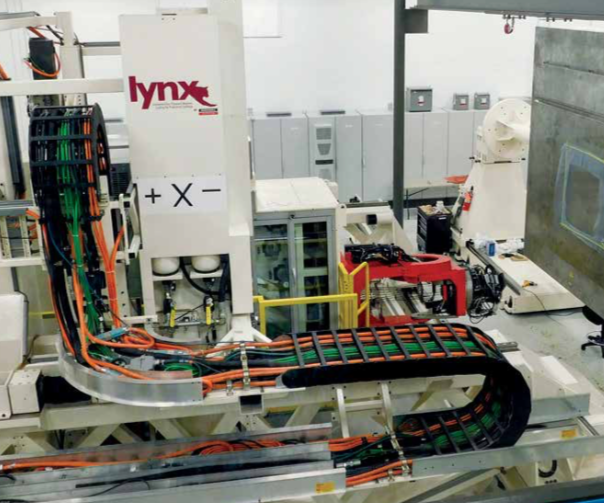

A tour of the McNair Center evidences the industrial, hands-on orientation of the work there. One centerpiece is the Lynx Fiber Placement Machine from Ingersoll Machine Tools Inc. (Rockford, IL, US), reportedly the largest AFP machine in a US research university (Fig. 1). Able to lay down 16 0.25-inch/6.45-mm tows per pass, this production-level machine is producing test articles for the center’s exploration of an unconventional steered-fiber laminate design, as well as dry fiber placement using HiTape unidirectional reinforcements from Hexcel Corp. (Stamford, CT, US). As test articles are fabricated on the AFP machine, a head-mounted Ingersoll profilometer collects inspection data and the system analyzes actual fiber placement. Any flaws (e.g., twisted or missing tows, foreign objects or debris) are highlighted by a LASERGUIDE laser projection system (Aligned Vision, Chelmsford, MA, US), enabling immediate error correction. (Learn more about the center’s AFP capabilities in the CW news post “McNair Center installs Ingersoll Lynx AFP machine”.)

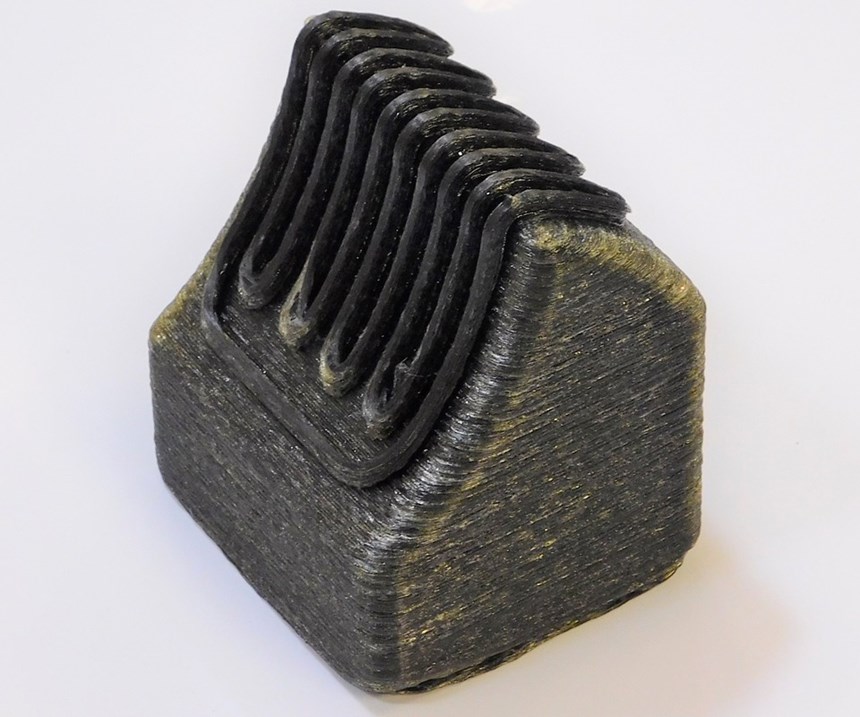

Fiber steering is a focal point of McNair Center research, and equipment like the Lynx system enables a design-for-manufacture orientation, points out Darun Barazanchy, a post-doctoral researcher. Barazanchy is performing interlaminar shear research to develop optimized paths for fiber steering. He says that his research benefits from the fact that the Center is fully equipped for fabrication (Fig. 2): “We can actually build it. We can do our predictions, optimize the design, manufacture and actually test it.”

“You can see how hard it is to move from paper or software to an actual panel,” he continues. “In the simulation world, you may see that something is optimum, but is it optimum in manufacturing?” As part of his research, Barazanchy is identifying the ways in which certain manufacturing parameters affect performance. These include not only more obvious factors, such as tow width, but also the less obvious, such as the fabrication starting point — whether the AFP starts at one side or the other, or in the center of the tool.

Also central to research at McNair, a fusion bonding laboratory supports the induction welding project, as well as VARTM, friction-stir welding, and other fusion-based assembly technologies. Other McNair facilities support advanced composite material systems, using plasma treatments and grafting; nano-particle-based interlaminar interface improvements; and 3D printing of continuous fiber-reinforced parts (Fig. 3).

The McNair Center currently partners with nearly 40 industry, educational and government organizations. The Center’s work with composites industry companies has proven mutually beneficial. The latter provide equipment and personnel who help McNair students use it to develop practical knowledge and skills, and aid the Center as it advances innovative technological developments to the brink of commercial applicability — at which point those innovations may be handed off to the industry partner. Industry-based researchers may also enlist the McNair Center for laboratory services in support of their work, including product development and prototyping as well as testing and evaluation.

Workforce development

Students who have earned master’s degrees through McNair are already enriching the composites industry in South Carolina and beyond. Graduates have entered the employ of Boeing and other aerospace companies, and have come aboard at US composites companies, such as Carbon Conversions (Lake City, SC, US) and Crawford Composites (Denver, NC, US), as well as equipment supplier Ingersoll Machine Tools.

Outside of the master’s programs, several efforts at McNair promise to grow the composites workforce well into the future. In the K-12 arena, for example, the center partners with organizations that promote curricula, camps and other activities tied to STEM-centered education programs.

To spark interest among undergraduates in composites technology, McNair has been offering courses, such as Basic Mechanics of Materials, to USC juniors and seniors as part of the mechanical engineering aerospace minor. It also awards a McNair Junior Fellowship to USC undergraduate students as early as their freshman year.

McNair Junior Fellows are assigned to work with McNair graduate students and faculty, and enjoy access to McNair’s technologies and facilities. “We try to help these students discover what they like,” van Tooren says. “They can figure out if they are ‘made’ for experimental work.” After three semesters, Junior Fellows are invited to apply for research assistant positions at the Center.

The Center’s professional outreach program, McNair Advance, offers certification in CATIA as well as other training courses to support professionals who work in the more than 500 aerospace companies with facilities in South Carolina. Course subjects include An Introduction to Composites Design and Manufacture, Vacuum Infusion, Introduction to Robotics, and Airframe Structural Design. Through McNair Advance, USC is one of only two US universities recognized as a Dassault Systèmes (Vélizy-Villacoublay, France) Certified Education Partner.

Offering courses for professionals was new ground for those at McNair. It involved both faculty and non-faculty staff, and getting the program up and running at the Center involved some trial and error. “At first, we thought we could just advertise short courses and people would sign up,” van Tooren recalls. “They don’t! So, it must be very targeted. Now our courses are offered ‘on demand.’” Siemens (Munich, Germany) is a large sponsor of McNair, having provided all its software; a recent pilot course was focused on Fibersim. McNair also put on a vacuum infusion course sponsored by DIAB International AB (Laholm, Switzerland), and a course on dry fiber technology.

A growing footprint

Given the above, it’s no surprise that the McNair Center is expanding its facility’s initial 1,395m2 workspace to 2,648m2 in 2018. The number of faculty, students and industry partners is expected to mirror this growth. More significantly, the McNair Center intends to continue to grow its impact on composites innovation, application and workforce in the coming decades.

Related Content

Zeiss, Imperial College London summer school enhances materials, sustainability learning

Twenty-four next-generation students attended the Imperial College London this August to advance their scientific knowledge, with workshops, lectures, activities and a composites competition.

Read MoreWomen in the Composites Industry brings together women for networking, educational opportunities

Aiming to support the growth of women in this industry, the WCI industry group and its partners recently held its first live training event hosted by Owens Corning.

Read MoreReducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read MoreAMRC Training Centre introduces composites apprenticeship opportunity

With partners McLaren and Teledyne CML Composites, the Training Center will train new composites technicians in South Yorkshire to build up the future industry workforce.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More