Measuring and improving fire resistance in composites

Sidebar to CW’s Feb 2019 feature article, this quick review of fire tests for composites also provides more details about intriguing new material developments.

FR composites primer

Composites have been used in fire resistant applications for decades. Generally, inorganic fibers (e.g., glass, carbon, basalt, ceramic) and inorganic matrix materials (e.g., ceramic/carbon, metals, polysialate/geopolymers) do not burn and most can withstand high temperatures. However, when most organic fibers and polymer matrices are exposed to high temperatures and fire, they will decompose into:

- non-flammable volatiles (e.g., CO2, water)

- flammable volatiles (e.g., CO, methane), which react with oxygen to feed the fire

- solid carbonaceous char

- smoke that can include toxic fumes.

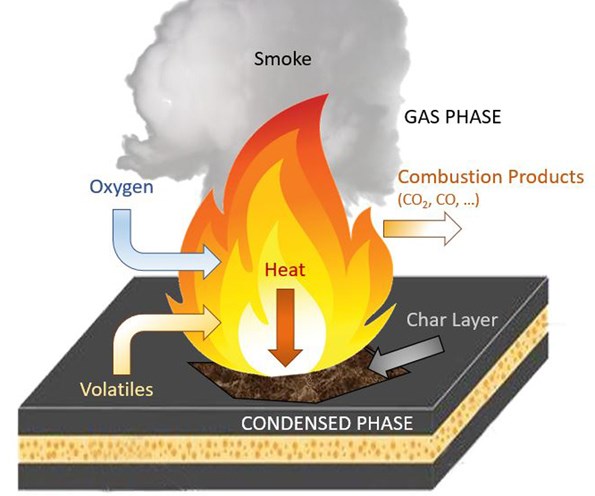

Fig. 1 Fire retardants and their mechanisms in composites

During a fire, polymer composite materials decompose, releasing volatiles (GAS PHASE) which can react with oxygen to feed the fire and creating a char layer (CONDENSED PHASE) as well as smoke. SOURCE | CW

A composite’s fire performance is measured by a variety of characteristics, including:

- Ignition

- Ability to self-extinguish

- Flame spread

- Burn through

- Heat release

- Smoke generation

- Smoke toxicity.

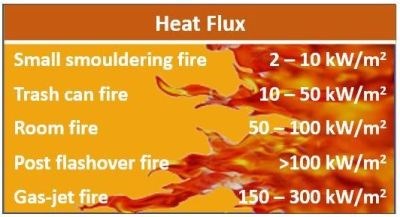

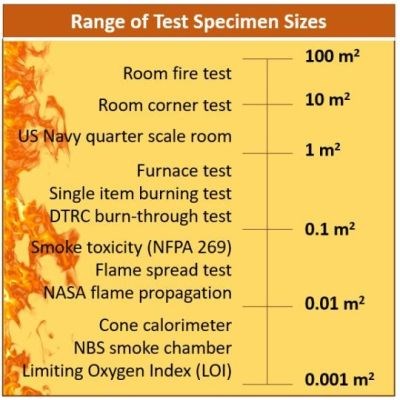

Limiting oxygen index (LOI) is also frequently cited. It measures the minimum oxygen concentration (in vol%) necessary for combustion; thus, higher LOI means higher flame resistance. The standard tests for these performance measurements vary by industry and range in test sample size from small coupons to full-scale constructions representative of in-service use. The flame heat flux used in these tests also varies.

Fire Test Measurements

(HRR) Heat Release Rate (kW/m2) ― the amount of thermal energy per surface area. Heat released during combustion provides thermal energy which develops and spreads the fire.

(pkHRR) Peak Heat Release Rate (kW/m2) ― highest point on heat release curve (plot of HRR vs. elapsed time).

(LOI) Limiting oxygen index ― minimum oxygen concentration (in vol%) necessary for combustion. Higher LOI means higher flammability resistance. Standard test methods include ISO 4589 and ASTM D 2863.

(TTI) Time To Ignition (s) ― onset of combustion, first event observed in cone calorimeter test.

(FPI) Fire Performance Index (sm2/kW) ― TTI/pkHRR. Higher values indicate better FR performance.

(FIGRA) Fire Growth Rate (kW/s) ― HRR/TTI

Bio-based phenolic/furan

CW’s Feb 2019 feature article discusses recent developments in prepregs using polyfurfuryl alcohol (PFA), which is made from from agro-waste biomass (e.g., corn cobs, sugar cane bagasse). This product has a long history, with TransFuran Chemicals (TFC, Geel, Belgium) claiming more than 40 years of production and annual capacity of 40,000 metric tonnes (MT). The company’s BioRez and Furolite resins are VOC-free liquid thermosets with a PFA backbone and Tg>180°C, available in a range of viscosities and formulated for different processes including resin infusion, prepregs and snap-cure compression molding. Cure temperatures range from < 95°C for infusion resins to >120°C for prepregs. These resins have been tested in composites that meet aircraft, rail and marine fire performance requirements. For more details, see TFC’s presentation from the June 2018 meeting of E-LASS (European network for lightweight applications at sea).

Bio-based phthalonitrile to replace PMR-15

The US Navy is also pursuing bio-based FR composites. It is funding a Strategic Environmental Research and Development Program (SERDP) to replace the 600°F capable polyimide resin PMR-15 with a sustainable resveratrol-based phthalonitrile (PN) resin. The goal, according to Navy research chemist Dr. Matthew Laskoski, is a high-performance thermoset that does not rely on toxic methylene dianiline and can be processed below 200°C yet performs well when fire tested per ASTM E 1354-1. First generation PN composites actually achieved this but were derived from petroleum-based bisphenols and were also hard to process. Alternatively, resveratrol is already being produced commercially via fermentation of sugars with engineered yeast. Testing of second generation PN composites, fabricated by hot-pressing E-glass-reinforced prepreg, showed better ignitability, heat release and mass loss rate performance vs. state-of-the-art glass fiber/polymer composites. The resveratrol-based PN composite retained 95% of its weight at 700°C and offers an easily processed resin system with exceptional fire-resistant performance at high heat fluxes. The team has also completed award-winning development on bio-based cyanate esters.

Self-extinguishing, inorganic polymer composite foams

Another green development, this one in India, concentrates on fire-retardant, self-extinguishing inorganic polymer composite foams. As explained by Dr. Guruswamy Kumaraswamy, at the Academy of Scientific and Innovative Research, (AcSIR, New Delhi), “we have demonstrated a polymer foams with a very high inorganic content that do not use FR additives yet exhibit exceptional fire retardance in burn tests. They are self-extinguishing, do not drip or collapse when exposed to flame and show a 75% lower peak heat release rate than commercially available fire-retardant polyurethanes.” These hybrid foams are prepared using ice-templating with a green solvent, water, as a porogen (pore-inducing material). They also show excellent mechanical properties. “We can use ice-templating to produce hybrid foam from cheap commercial materials and our approach appears to be chemistry-independent within a wide range of materials,” says Kumaraswamy. “We’ve also shown that we can play with the crosslinking density to increase modulus by more than 100-fold, and there is no loss of elasticity with increase in modulus.” Though he has not tried harder foams, he believes it should be possible. His team’s interest has been to produce high-performing FR foam for automotive seats, but the overall approach may hold promise yet for various composite insulation foams, especially as the process has already been scaled without loss of mechanical performance or fire-retardant properties.

The MAI Sandwich research project has demonstrated an automated process for molding PES foam and thermoplastic CFRP laminates into lightweight shaped parts with overmolded features and high fire performance. SOURCE | lightweight.design magazine

PES sandwich laminate for FR aircraft interiors

Interestingly, polyethersulfone (PES) is one of the chemistries demonstrated by Dr. Kumaraswamy’s team in their development of hybrid polymer/inorganic foams. It is also the polymer used in the “MAI Sandwich” research project demonstrating an equally fire-retardant alternative to phenolic-based aircraft interiors. A sandwich comprising foam core and CFRP laminates, all made using Ultrason E PES from BASF (Ludwigshafen, Germany), was processed into 1-3 m2 panels in less than 5 minutes. The automated process combined themoforming the foam and composite faceskins followed by immediate overmolding with 30% carbon fiber-reinforced Ultrason E compound to integrate additional functional elements (e.g., ribs, fastener attachments) into the final shaped part. With a high LOI of 38, Ultrason E meets all FST requirements for commercial aircraft without adding flame retardants, making this process well-suited for interior side walls, luggage bins, doors, cabin partitions and galley components. The project won the 2018 JEC Innovation Award in the Aerospace Process category. For more information, read the online article by CW media partner lightweight.design magazine:

https://link.springer.com/article/10.1007%2Fs41777-018-0019-7

See the February 2019 feature “Withstanding fire without the weight” for more on fire-resistant composite materials.

Related Content

JEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreComposites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More