Plant tour: FBM Composite Materials, Kiryat Gat, Israel

Tier 2 composites manufacturer FBM Composite Materials developed the right pill for a Boeing headache and became the sole supplier of 787-9 Dreamliner door surrounds.

Share

If FBM Composite Materials Ltd. (Kiryat Gat, Israel) is any indication, Israeli companies love a challenge. Despite no composites experience between them, three firms agreed in 2006 to form a new subcontracting entity that would produce composite parts for Israeli Aerospace Industries (IAI, Lod, Israel). What they lacked in experience they made up for in entrepreneurial spirit, as aircraft parts and equipment provider Fedco Israel Ltd. (Emek Hefer, Israel), sheet metal-forming specialist Baz Airborne Components & Assemblies (Bar-Lev Industrial Park, Misgav, Israel) and a third company, MLR Technology Ltd. (Rishon LeZion, Israel), came together to create FBM.

“IAI was looking for an ‘extended arm’ partner to make small and medium structural parts for The Boeing Co.’s [Chicago, IL, US] 787 aircraft, so the three companies merged,” says FBM’s VP of marketing and business development and deputy CEO Nissim Poliker. “I am proud to be the first employee, badge No. 1.” Twelve years later, FBM is a fully certified and qualified Tier 2 subcontractor, with 140 employees, situated in a large business park anchored by technology giant Intel, southeast of Tel Aviv. FBM is currently the sole supplier of the 787-9’s carbon fiber composite door surrounds, and much more

Agility, from the ground up

Poliker and Beni Manes, formerly with IAI, who joined FBM as CEO last year, provide CW a company history in an upstairs conference room at FBM’s main office, located in the larger of FBM’s two buildings. “The first tools built for the 787 were built by FBM!” Poliker brashly begins. “We built 805 tools for the door surround parts in six months, both in-house and with a subcontractor, for the aircraft.” He explains that he and a handful of employees did much of the early work, making test parts and establishing the composite part production process.

In 2007, FBM took steps to become more independent from IAI, by contracting with other OEMs, but 787 contract orders decreased as the effects of the US Great Recession spread worldwide, and by 2009, only 12 employees remained. But, with time, the Boeing work restarted, and on July 31, 2011, Boeing representatives came to FBM to qualify the company. Only four months later, FBM passed the last of Boeing’s stringent requirements and, on April 29, 2012, was officially listed as a Boeing Qualified Supplier.

More recently, FBM’s client list has expanded, which Manes and Poliker attribute to its good quality system, fast development cycle and agility, which extends to its ability to produce tools quickly. The focus is on complex, high-quality, composite parts: “We want to be in the niche of high-quality composite parts that are challenging or complicated, which suit our capabilities.”

That effort has been successful: FBM is now a qualified supplier to a notable list of aerospace entities that includes Spirit AeroSystems (Wichita, KS, US), Triumph (Hinkley, UK), TASL (a division of Tata, Hyderabad, India), Gulfstream (Savannah, GA, US), RUAG (Bern, Switzerland) and Leonardo (Rome Italy). Poliker adds that FBM’s strength is handling others’ headaches. FBM doesn’t create them, it cures them. “It’s all about people, giving them service, keeping in touch,” he adds, emphasizing, “The airplane needs to be delivered on time.”

Manes cites, for example, the case of Eviation Aircraft (Kadima-Tzoran, Israel), a fast-growing startup focused on development of an electric business-jet concept. Eviation came to FBM in January 2017 with a smaller drone concept, the Orca, and a general design. FBM was able to build tools, design the fuselage and wing, come up with the rest of the Orca’s shapes and fabricate all its parts in carbon/epoxy prepreg to realize the aircraft in time for the Paris Air Show, six months later.

Says Poliker, “For that project, we wanted to think outside of the box. They needed high performance because of the electric drive, so we wanted to really come up with a new way to develop a robust manufacturing process.” Since then, Eviation’s electric Alice business jet has generated considerable media buzz, and FBM may be involved with its future builds.

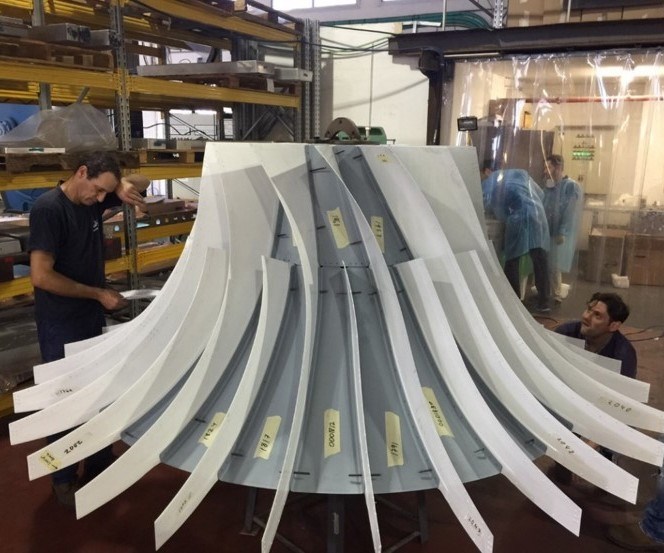

Another interesting project was the fabrication of high-speed impeller rotor blades for IDE Technologies (Kadima, Hasharon Industrial Park, Israel), a global company involved in desalination and water treatment and other types of water projects. FBM handled both its design and manufacture. “Few others could have made this part, and several other companies tried,” says Poliker. “We don’t use a normal process to lay these up and create the internal structure, but they are autoclaved.” And he adds, “The design was difficult.” The impeller has a diameter of 2.5m, turns at 3,600 rpm, with a Mach1 tip velocity. The blades are complexly shaped with tapered thickness, made with hybrid materials (carbon and glass with epoxy) and an internal stiffening rib; 70 blades make up the impeller, with the blades mounted on a titanium hub.

After a closer look at the water impeller blades, Poliker concludes, “Look, the project demands are clear, the specs are clear, but there are many ways to process these materials to reach the goal, within our culture of quality.

Organic growth

Poliker begins the FBM tour in the building FBM calls the “blanks manufacturing site,” across the street from the main office. CW is led first to a cleanroom, where workers lay up a variety of parts. This day, at a number of stations, each equipped with a computerized layup-assist computer screen, the focus is parts for the Boeing 787. Easy-to-understand touch screens clearly show the layup angles for each ply, and how they’re to be positioned on each tool. A “guillotine” machine from Century Design (San Diego, CA, US), with a 2m-diameter rotary table and knife blade in the center, enables fast cutting of angled plies from the carbon/epoxy prepreg. Tools for the 787 door surrounds are shaped steel mandrels, typically longer than wide, from a few centimeters long up to ~2m in length, used to produce hundreds of frames, brackets, and clips. An automated flatbed cutting table from Assyst-Bullmer Inc. (Wakefield, UK) is used by the layup technicians to cut up to 50 stacked plies in one operation.

The cleanroom is dominated by a hot drape former (HDF). Made by ElectroTherm Industry (Migdal HaEmek, Israel), the static machine (the company also makes moveable versions on carts) is a custom-made, vacuum-forming system, equipped with infrared heating elements and a silicone rubber membrane to heat and compress the composite layups on the tools, prior to cure. The HDF can shape as many as 50 stacked plies, says Poliker, with no intermediate debulking steps: “We were looking to eliminate process complexity, so we form the layups in one shot.” After the prepreg is heated and consolidated in the HDF, a caul is placed over the entire layup, prior to bagging. Made with a carbon fiber composite, the caul exhibits a rough surface finish. Poliker won’t reveal details of the proprietary material, but does say it can take the 177°C autoclave cure temperatures: “It simulates a matched-die tool.” He adds that the mandrel tools are reconditioned in-house, as needed. Bagging and consumables are supplied by Airtech International (Huntington Beach, CA, US).

Given a 787 production rate that varies from 12 to 14 shipsets per month, FBM looks for any time savings to improve efficiency. When asked if the company employs digital production methods, Poliker says, “We’re not paperless, but we operate with less paper,” pointing to the computer screens at the layup stations as one example. He adds that Plataine’s (Tel Aviv, Israel and Waltham, MA, US) material tracking system is on FBM’s technology-acquisition agenda , and that FBM will function as a demonstrator of the technology for other Israeli firms.

When parts are ready for cure, they are loaded into one of three autoclaves in the building. Two were supplied by Scholz Autoclaves (Coesfeld, Germany), having dimensions of 2.6m by 7m. The smallest vessel, supplied by Terruzzi Fercalx Group (Spirano, Italy), is located within the original building’s footprint; Poliker explains that FBM has, since incorporation in 2006, expanded that first building significantly, in three phases: “The secondary building, devoted to composites, was 250m2 when we started, and today the building is 2,500m2. We always had an expansion plan.” What was the original, small cleanroom and layup area is now the materials testing lab.

Poliker leads the way back across the quiet business park street to the main building and into the part-trimming and machining area on its ground floor. Two CNC machining centers, one from Haas (Oxnard, CA, US) and the other, a 4m, 5-axis machine from Breton SpA (Castello di Godego, Italy), perform trimming and drilling of the various parts. Among them are 787 door surround components. Part inspection and scanning occur in an adjacent room. Poliker says the C-scan procedure that is used there is FBM’s own technology: “We are very careful about the inspection,” he emphasizes, “We don’t want to hear about bad parts.”

A total of 180 parts make up one ship set for the 787 door surrounds, with 160 unique parts. Each of these get edge-sealed for durability after machining. Holding one of the finished door surround parts in his hand, Poliker points out that the edge-sealing process also gives the part a smooth finish. “Composite parts should be nice, should have a good appearance,” he maintains. “Our name is on these, so we make them beautiful.”

FBM certainly embodies the Israeli spirit of overcoming challenges and solving problems, and Poliker adds, “We always wanted to be an aviation supplier, and we have accomplished that goal in a short 12 years.” Bent on putting its name proudly on many more composite parts, this headache-curing company is definitely on a growth trajectory.

Related Content

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More