Meter/mix/dispense machines: The suppliers and systems

HPC’s meter/mix/dispense (MMD) roundup includes this collection of the principle suppliers of MMD equipment and equipment characterizations.

HPC’s meter/mix/dispense (MMD) roundup includes this collection of the principle suppiers of MMD equipment, presented ere in alphabetical order:

2KM North America (2KMNA, Williamsville, N.Y.) Derived from 2 Komponenten Maschinenbau (2 Component Machine Engineering), this Germany-based, family-owned company has supplied more than 5,000 machines since 1976. It has a large facility in Germany and in the U.K., as well as operations in Canada, the U.S. and Asia. Its PolyMix and PolyTool systems are used for application of adhesives and tooling pastes. Its ResinMix equipment is used for resin infusion, offering variable mix ratios and flow rates from 1 to 60 liters/min (0.3 to 16 gal/min) with inline vacuum degassing and heating options, which reduce component preparation time and wastage.

2KM’s ProcessGearMix RTM was introduced at the JEC Europe 2013 show, developed specifically for injecting resin into a closed, pressurized mold. Although the system can be upfitted with all of the material conditioning (heat and degas) and advanced control options (flowmeters), it is described by 2KMNA managing director Gary Bauer as “A simple, easy-to-use machine that enables control of the RTM or infusion process yet is cost-effective.” He adds that 2KM tries to strike a balance between having standardized products to keep costs down and maintain reliability, “but then there are new developments and specialty niches which require unique setups, plus 2KM’s main strength is developing innovative solutions for challenging processing needs.”

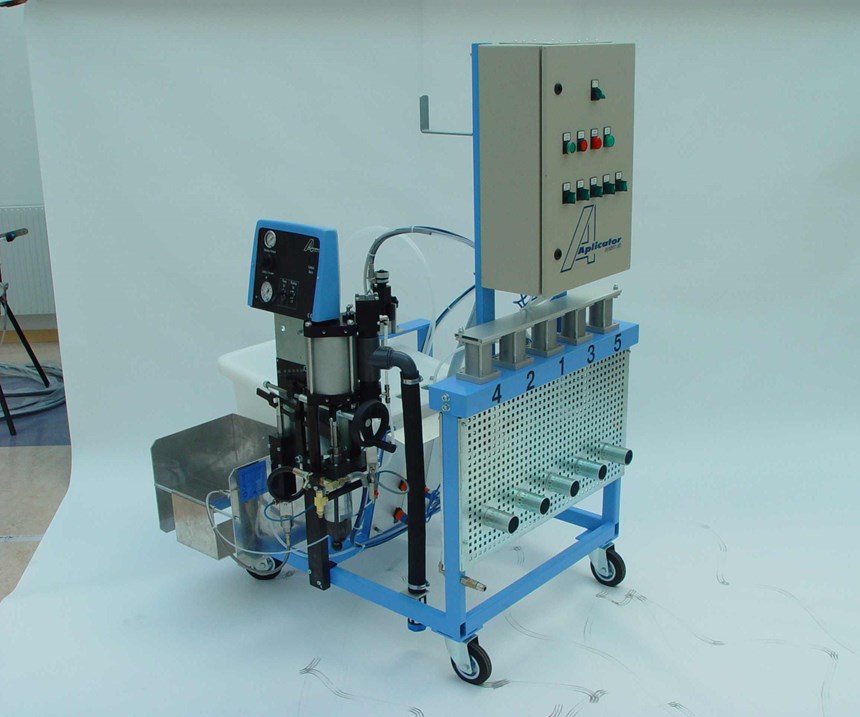

Aplicator Systems AB (Mölnlycke, Sweden) has supplied a variety of MMD equipment to the composites industry for more than 30 years. Its current systems include the Ri2 for RTM and the IPP-8000/T200 for application of mostly polyester and vinyl ester adhesives in wind blades. Its VIM5 systems, used for vacuum infusion, include up to five outlets for attaching resin feed lines into the mold, which can be automatically opened and closed sequentially. These are mainly used for making wind blades and marine hulls and decks using polyester, vinyl ester or epoxy resins.

One trend noted by Aplicator’s marketing VP Clas-Åke Johansson is the recent growth in automation of glass fiber preforming. “We introduced our P4 machine for use in automotive with epoxy and polyurethane years ago, but only now are getting a lot of requests.” This robotic system quickly builds up the preform using standard spray roving, which is a cheaper raw material. Johannson admits the increased speed and automation requires a greater investment than more traditional equipment, but that is seen as necessary for high series production.

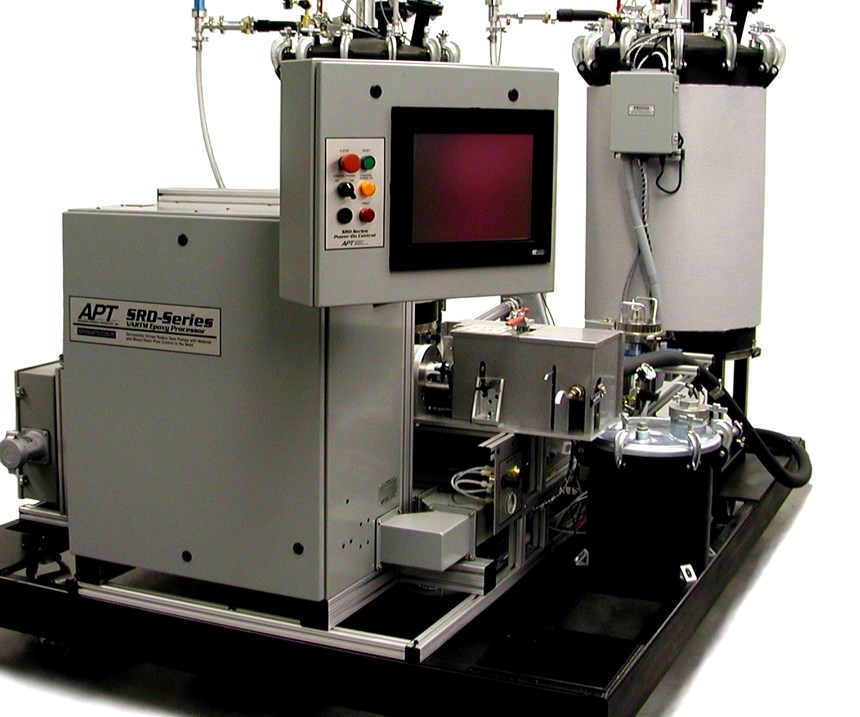

Advanced Process Technology (APT, Middlesex, N.J.) has supplied MMD equipment since 1969. Its SRD Series, used for closed molding, reportedly blurs the line between continuous flow and metered shots. “You can run the machine continuously to make a shot size of 100 or 1,000 lb [45 kg or 454 kg] of material while maintaining the ratio between two to five component materials being supplied,” explains Hap Phillips. “We also have machines that will dispense shots as small as 7 grams [0.25 oz].”

Phillips says that one SRD machine could be used for both RTM and VARTM, but because the pressures are so different — hundreds of psi for RTM vs. less than atmospheric pressure for VARTM — adaptations would need to be made, such as switching out pressure sensors. Though the SRD series uses rotary gear pumps, they reportedly can handle fillers but only up to a certain mesh size and volume. Above those levels, Phillips recommends the ECS Series, which uses servomotor-driven push-pull piston pumps and flowmeters.

Ashby Cross (Newburyport, Mass.), founded in 1976, supplies MMD equipment to industries such as electronics, electrical, white goods, defense, marine, recreational, solar and others. In addition to composites applications, Ashby Cross supplies equipment for potting and encapsulating, molding, cable sealing, casting, two-part coatings spray and areas where two-part adhesives are used.

Two basic designs are used in these applications, piston metering and gear metering. Gear metering makes use of two high precision gear pumps that accurately meter specific amounts of material to achieve the designed mix ratio. Said to be very accurate and simple in design, the advantage of a gear pump is the ability to adjust flow and ratio on demand. However, Ashby Cross does not use the gear pumps in composites molding due to the slip inherent in their design. Also, in potting and encapsulating electronics, the potting material often contains abrasive or a high content of fire retardants, which can create problems in the gear pumps that can include high wear. Instead, piston-type metering systems are used in applications with changing back pressure or with heavily filled materials. These are designed for highly abrasive service and can handle almost any viscosity or filler loading. There are two types of piston metering systems, single-acting and double-acting. The single acting system fills then dispenses, with no output when it is filling (recharging), hence the "single acting."

The 2500 Double Acting Dispense System has been developed for RTM and other composites molding operations. Double acting refers to its dispensing at one end of the machine while filling in behind so that output is continuous compared to a single acting system. A fixed mix ratio is obtained via the volume of the cylinders used for part A vs. part B and metered by pneumatically driven piston pumps. when linear encoders are used, both dispensed volume and mix ratio can be controlled to a reported accuracy of ±1 percent. All of the process parameters are managed within the machine’s programmable logic controller (PLC). The 2500 can be used with epoxies and urethanes, and can maintain up to 1,000 psi in the mold, but sales and marketing director Don Leone says most RTM processes operate fara below that level.

The 1125 Variable Ratio IDS is a benchtop version of the company’s piston metering systems, said to be ideal for R&D or low volume closed molding. The single-acting system features two cylinders, which fill and dispense on ratio. The shot size is determined by an encoder mounted on the metering cylinders. When the shot size is set on the PLC, the system dispenses exactly the amount needed. The PLC continuously calculates the amount remaining in the cylinders and alerts the operator if the volume remaining is not sufficient. The machine then automatically recharges (refills)

Graco (Canton, Ohio) is a global supplier of fluid handling equipment for chemical processing, molding, assembly and finishing applications in a wide variety of industries. The company’s AFD division designs and supports resin proportioners and dosing equipment for inline prepreg meter/mix, RTM, pultrusion, filament winding, Infusion and PUR spray systems. The Hydraulic Fixed Ratio Metering System, or HFR, is a versatile proportioning platform that can be configured for any of the above applications. This reportedly makes it ideal for companies that are proving out different composite manufacturing processes and then want to scale up for high-volume production without changing equipment technology. The HFR can be programmed for constant flow rate or constant pressure. Mac Larsen, director of application development, explains, “With RTM or Infusion applications you want controlled flow but also want to limit injection pressure at the end of filling cycle. This will prevent separation or deformation of the RTM tool.” The HFR can maintain mix ratios from 1:1 to 30:1 and flow rates from 3 to 4 cc/s (0.1 gal/min) to more than 300 cc/s (5 gal/min). Larsen describes this as a “mid-size machine.”

Graco’s VRM is a high flow system delivering up to 66 lb/min (30 kg/min) designed for use in infusing wind blades and large boat hulls. The mix ratio can be programmed from 1:1 up to 5:1. The VPM machine is similar, dispensing up to 55 lb/25 kg per minute for application of adhesives and tooling pastes. Graco’s PR70 system is a low-flow benchtop design available in either fixed or variable ratio configurations. It can be set up to preheat and vacuum degas small quantities of resin and hardener and it also can be adapted with large-volume reservoirs for production. Because less material is required to fill up the machine, it allows parts trials with only a few gallons of resin. All of these machines process epoxies and polyurethanes, while styrenated resins (i.e., polyesters and vinyl esters) are handled by Graco’s FRP line of products. The Graco/Glascraft proportioners, when coupled with the company’s new RS gel coat or chopper guns, are reportedly proven FRP manufacturing tools for high-volume FRP shops.

GS Manufacturing (Costa Mesa, Calif.) is a family-owned business that has made MMD machines since 1971 for spray up/chopper gun, RTM and infusion, and adhesive/putty application. “We designed a polyester putty dispensing system for Sea Ray 20 years ago and were the first to design a system to dispense Plexus MMA adhesives,” says vice president Gary Smith, Jr. The company also supplies machines into the wind energy industry. “A Brazilian wind blade manufacturer has 80 of our systems, including 60 for epoxy infusion,” notes Smith. He explains that his company stresses keeping things simple and tries to moderate system cost rather than pushing all the “bells and whistles.”

“The epoxy infusion systems could be fairly simple because the resin viscosity is so low,” he adds, “but the flowmeters are usually stainless steel, due to the resin chemistry.” He sees an increase in requests for electronic controls, but points out these are expensive. So GS specializes in how to customize at a lower cost. For example, for highly filled materials, the company will use a shovel pump that is similar to a piston pump but does not use a ball and a seat. Smith notes, “It is good for very viscous materials, say 1 million cps, so we buy this and modify it in our own machine shop.” He cedes that GS is a smaller company, but maintains that this fact makes this type of in-house modification easy and helps the company to build customized systems quickly.

JHM Technologies (Fenton, Mich.) says its passion is for the whole infusion/injection composites molding process, not just the MMD componentry. President John Moore explains, “You have to understand the complete molding process and aim to improve your customer’s control of that process.” Moore aims to reduce the operator skill and intervention requirement through cost-effective automation, allowing for optimal process control and lower end-product cost. Its entire Infuser series of equipment features a design built on what JHM terms a solid foundation, because its designer had had actual production molding experience, a scenario that Moore claims no other equipment manufacturer currently offers. This reportedly enables unmatched process control performance. The Infuser PRG system is used for polyester and vinyl ester. JHM’s Infuser SVO EPX, on the other hand, is better for single- and plural-component epoxies and polyurethane applications that require absolute precision control with thin laminates and CFRP.

Kirkco (Monroe, N.C.) provides custom (design to build) application specific systems and distributes equipment made by Hilger u Kern (HUK)/Dosiertechnik und Pneumatik (DOPAG Group, in Cham, Switzerland) and Wagner (Markdorf, Germany). “We use our application expertise and know-how to select from a wide variety of valves, mixers and pumps, and combine them to meet our customers’ specific processing needs,” says vice president Scott Kirkpatrick. Its ELDO-MIX is a high-volume system used for delivering continuous pressure and flow for low- to medium-viscosity, unfilled two-component resins.

Special versions are available for high-viscosity filled materials. Mix ratio is variable, set by adjusting the electric motor speed for the gear pump, and can be maintained to ±1 percent accuracy by the process computer. Material can be dispensed in metered shots or a continuous flow. Primary composite applications are resin infusion, RTM, pultrusion and gel coating. Systems are also suitable for potting, casting, and coating processes. A variety of different machine platforms provide a range of output volumes and degrees of computer-controlled automatic operation, monitoring and documentation options.

Its COMPOMIX product family is specialized for high-volume vacuum infusion and application of thick adhesives in wind blade production and shipbuilding applications.

Kirkco’s VISCO-MIX system uses two reciprocating hydraulic piston pumps for filled/abrasive resins, providing what is described as infinitely variable proportioning by adjusting a mechanical lever to the desired mix ratio. VOLU-MIX uses precision gear pumps and flowmeters to provide high-accuracy, mixed two-component adhesives or sealants for cartridge filling or on-demand process applications.

Magnum Venus Plastech (MVP, Clearwater, Fla.) has mainly supplied systems for polyester resins and gel coats into marine, tub/shower and other composite markets, but also makes equipment for adhesives, epoxies and polyurethanes. “We are doing more of these specialty materials than ever before, due to the growth in closed molding, and we have expanded our product line since the mid-2000s,” says VP of sales and distribution, Jeff Austad.

MVP’s PATRIOT pump systems are used for non-atomized spraying of resins and gel coat as well as closed molding processes. These machines use two-ball, double-acting piston pumps built in-house with specific improvements. “There is a brief moment at the top and bottom of a piston stroke where the percentage of resin and catalyst can be off,” Austad notes, pointing out, “Our design enables a very smooth, quick switchover so that metering is accurate throughout the pumping cycle.” He says the new, simplified design has fewer parts, for example, as well as fewer packings and seals that wear, resulting in reduced maintenance. PATRIOT also uses a one-piece fluid section that is reportedly more efficient, for lower cost. Low-, medium- and high-volume pumps are available with a variety of guns, including external or internal mix and manual or automatic operation.

MVP’s INNOVATOR Closed Mold Injecting System, which incporporates the PATRIOT pumping system, is used for RTM Light, closed-cavity bag molding (CCBM), RTM and infusion. It is entirely pneumatic with a control box, stroke counter and mold pressure guard to prevent overpressuring the mold. Austad explains, “You have an injection pressure, and then the pressure at the resin flow front. At about 75 percent of the way to filling the mold, these two pressures are very different. A pneumatic sensor in the mold senses pressure and communicates back to the machine control to slow the pump, and can shut the flow valve and stop the pump if required.” MVP also offers PLC and radio-frequency identification (RFID) controlled systems for more advanced applications.

MVP’s HYPAJECT offers increased control for small batch production, R&D and aerospace type component fabrication with resins that need to be vacuum degassed and heated in-line vs. traditional batch processing. A 6-liter capacity is standard but special order sizes are available from 0.3 to 30 liters. It uses the pressure-pot principle to draw in premixed resins under vacuum, actively degas and heat (optional), and then dispense under pressure into the mold. Developed for single-part epoxies, such as Hexcel’s (Stamford, Conn.) RTM6 and Cycom 890 RTM from Cytec (Woodland Park, N.J.), it also can handle some polyesters, vinyl esters, methyl methacrylate (MMA), phenolic, and multicomponent epoxy resins.

Unlike most other MMD companies, Mahr Metering Systems (Charlotte, N.C.) manufactures its own gear pumps. Mahr began building them for the synthetic fiber industry, where the pump operates 24/7 under extreme temperatures and pressures. Most of Mahr’s MMD equipment is custom-made to meet specific customer requirements and can be modified easily meet future needs. “That standard equipment can be bought off-the-shelf is a big misconception in the industry,” says Mahr’s president Mark Cauthen. He cites Marmax as the most standard product line Mahr offers, simple versions of which can be built quickly. But he notes, “More complex multi-component machines do take at least 12 weeks to manufacture.”

Cauthen describes high-viscosity equipment as a specialty item because some resins are “rock hard” and need to be heated. He adds, “This type of equipment is an investment, but because it actually meters directly from the drum/barrel, other downstream equipment is eliminated, and using a gear pump eliminates any transfer equipment.” Cauthen says increased use of PLC controls delivers a lot of flexibility in operation and points out that the microelectronics are now much more affordable.

Mahr has supplied a lot of RTM machines to dispense high- and low-viscosity materials into pressurized molds for aerospace manufacturers. These are typically configured to provide constant flow until the mold reaches the desired operating pressure, and then regulate other parameters to hold that pressure until the resin is cured. The company also provides equipment for adhesive application and melt-mixing inline, as well as in-line heating and degassing.

Nordson/Sealant Equipment & Engineering’s (Westlake, Ohio) two main composites markets are marine and aircraft, the latter a key segment for decades. Marketing manager Dave Mandeville says, “Here, we supply equipment for a wide variety of applications, including application of adhesives, sealants and potting compounds. All of the composite sandwich structures that have attachments have to have hard points where that local area is milled out and filled back in with a structural adhesive for inserting the fastener or attachment mechanism.”

Although the company does not supply equipment for infusion, the following models all can be used for RTM and application of adhesives, handling epoxies, PUR and 1:1 polyesters, but not wide mix-ratio polyesters. MMA is accommodated by using stainless steel for the parts that contact resin, and alternative surface treatments enable sufficient wear resistance for materials with very high filler contents. Its See-Flo 7 double-acting, two-ball pump system with pneumatic driven meter system, supplies continuous flow on demand. The pneumatic drive enables a lower cost. The Servo-Flo 704 also is a continuous-flow system that uses a servomotor-driven gear meter system for precise flow rate and volume control. The Servo-Flo 105 is a variable mix ratio system that allows resetting from 1:1 to 2:1, for example, without hardware changes for adjusting durometer (hardness/softness) and other material properties during different processing runs. This system enables pre-pressurization so that mix ratio is exactly as expected, for example, when there is zero tolerance for being off ratio at the beginning of a pour. This is important in small mold applications where even a very small percentage of off-ratio material at the beginning is too much of the total and would affect properties. Part A and part B can be adjusted individually. The Servo-Flo 505 is a fixed ratio system for protection of the ratio. In other words, it always runs at 1:1 or 10:1. Changing the mix ratio requires additional parts and a mechanical hardware change. The See-Flo 690 is a fixed ratio system used for small molding processes with air over oil pneumatic drive for consistent flow rate control and manually adjusted flow rate.

Windsys Solutions (Acworth, Ga.) is a distributor for DEKUMED (Bernau, Germany), which has been manufacturing MMD equipment for 30 years and has a lot of experience with two-component materials, especially in high flow-rate applications. All of the machines are based on standard modules, selected to handle different chemistries, filler contents and viscosities, and then combined to meet the custom needs of each specific customer and application. DEKUMED typically uses rotating gear or screw pumps with separate pump drives, reportedly enabling a very accurate mix ratio that can be adjusted on the fly. Monitoring and control of the mix ratio varies according what the customer requires, but most machines use flowmeters.

Related Content

NCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreJEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreCollins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More