Micro transportation: BMW personal mover concept

Recycled composites, additive manufacturing and 3D printing enhance form, function of fun-to-drive personal transport.

Share

BMW Group (Munich, Germany) is once again redefining transportation, this time with its Personal Mover Concept, an electrically powered mobile platform designed to carry a person and light cargo over short distances within operating sites as diverse as manufacturing facilities, airports or even theme parks. The unit, which is versatile, maneuverable, tilt-proof and clean-powered, can be used inside or outside of buildings and, most importantly, has been designed to be fun yet safe to drive.

The genesis of this project was the realization that many of the automaker’s plants and logistics centers are sprawling campuses where employees can walk up to 12 km/day while carrying small parts and other work materials as part of their jobs. To make it easier and more efficient for employees to move around, BMW experts drawn from the Research & Technology House in Garching, Germany, and the central aftersales logistics network at Dingolfing, Germany, took up the challenge to create a mobility solution for their colleagues at other BMW facilities.

“Makerthon”

The team began the project by randomly surveying employees at multiple sites and recording their needs. In parallel, other team members conducted environmental analyses, reviewed site safety guidelines and considered legal issues. When combined, results from these studies presented the team with a list of demanding requirements that the new transport device would need to meet, including:

- safety and stability with no chance of overturning,

- ease of operation for most users,

- low cost to produce,

- light weight,

- space to include lights, horn and bell, plus two independent brakes,

- and a fun riding experience.

An evaluation of existing options did not provide satisfactory solutions that met the requirements. The team concluded that only a custom design developed in-house would work.

To encourage the team to quickly develop creative and unconventional ideas, a BMW design-thinking format called “Think Make Start” was employed. This involved use of agile methods to develop and evaluate ideas and prototypes in a sort of “makerthon,” a process originally developed by UnternehmerTUM.com and the Technical University of Munich (both Munich, Germany) for developing new products in only one or two week-long sessions. It was from this process that preliminary concepts for the Personal Mover emerged. Initial ideas did meet all of the preliminary project requirements but, according to the company, were deemed “to need too much technical and financial effort for simple and straightforward implementation.”

“Based loosely on the motto, ‘fail fast,’ we put our heads together after the makerthon and radically overhauled the concept,” recalls Stephan Augustin, BMW special projects team leader for research, new technologies and innovations.

“Using the ‘MakerSpace’ — a high-tech workshop for inventors and researchers that is open to the public on site at UnternehmerTUM — we created as simple a prototype as possible with the help of dedicated BMW apprentices,” adds Rainer Daude, BMW project director formobility concepts.

“That prototype met all the project’s main requirements and, unlike our initial concepts, it can be implemented much more quickly, easily and inexpensively with the expertise we already have in-house,” adds Augustin.

From concept to reality

As conceived via the design process, the Personal Mover’s body features a platform on which a person can stand comfortably and still transport some light objects. Two skateboard wheels are fixed under the rear corners and two more wheels, each capable of rotating 360 degrees, are positioned under the front corners for stability. This 360-degree wheel geometry helps keep the device highly maneuverable while also ensuring that — even when making tight corners — the unit doesn’t tip over. A fifth, larger drive wheel is positioned at the front under the handlebars and steering rod. The drive wheel, which provides acceleration, braking and steering, penetrates through the platform and is covered by a protective cone. Use of a larger wheel here provides better grip and performance. The handlebar itself houses the unit’s entire electrical system and battery and is directly connected to the drive wheel, which enables the driver to pivot the handlebars 90 degrees to left or right, permitting the unit to turn on a tight 1.2-meter radius.

All operator interfaces are mounted to the handlebar grips. Buttons on the display unit turn the vehicle on or off, select the driving mode, turn the lights on or off, and provide a check-battery indicator. On the right side, a thumb throttle regulates speed, while on the left side are a brake and a “dead-man’s” control button, which must be pressed for acceleration and will quickly stop the unit should the operator’s hand leave the handlebar for whatever reason. Because of the Personal Mover's quiet electric drivetrain, a bell is mounted to the handlebars so the operator can warn those walking in the vehicle’s path.

Much like the company’s i3 battery-electric vehicle (BEV), the Personal Mover is designed to use regenerative braking, which feeds kinetic energy back into the battery for recharging during braking. The electric drive accelerates to a maximum speed of 25 km/hr, although the units will not be permitted to exceed 12 km/hr at any BMW facility. Under normal use, the battery cells have a guaranteed range of 20-30 kilometers without a recharge. Recharging takes two to three hours and can be done via a household electrical outlet thanks to a power adapter. Occupational safety guidelines stipulate that permanent daytime running lights operate when the vehicle is in use, so it’s outfitted with a front light-emitting diode (LED) mounted on the handlebars and two rear LEDs, which are integrated with bumpers on the rear of the platform to ensure good visibility.

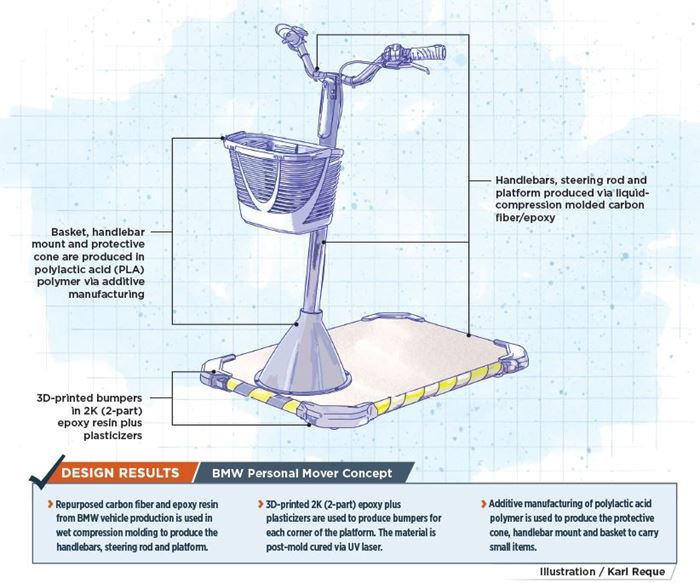

The steering rod, handlebars and body platform are made of repurposed carbon fiber-reinforced plastic (CFRP) scrap reclaimed from i3, i8 and M-Series models produced at BMW’s Lightweight & Engineering Center in Landshut, Germany. New parts are produced via dry preforms that are infused with epoxy resin during wet compression molding. Bumpers mounted at each corner of the body platform are produced using 2K (2-part) epoxy resin plus plasticizers via the Polyjet process on a printer produced by Stratasys Ltd. (Eden Prairie, Minn., U.S.) and then post-cured with a UV laser. This 3D printing process makes it possible to simultaneously build up both a hard, structural part as well as a soft outer skin to reduce damage during low-speed impacts. A small handlebar-mounted basket, the handlebar mount and the protective cone that covers the lower portion of the handlebar and drive wheel where both penetrate through the platform body are all produced via additive manufacturing processes — using polylactic acid (PLA) polymer either via fused-deposition modeling (FDM) or fused-filament fabrication (FFF) on printers from Ultimaker B.V. (Geldermalsen, Netherlands).

In its current form, the Personal Mover Concept is 60 centimeters wide, 80 centimeters long, 110 centimeters high (at the top of the handlebars) and weighs 20 kilograms.

Future steps

Initially, five prototype Personal Mover Concept units were produced and presented at a global BMW aftersale logistics meeting. Not surprisingly, it was well received.

The device — which is undergoing final design reviews and changes — will first be deployed at FIZ Future, BMW’s Research & Innovation Centre (FIZ) in Northern Munich, which at 1-million square meters, is already BMW’s largest facility and is undergoing another expansion. Beyond that, plans are to roll out the Personal Mover to other BMW sites worldwide. There is even discussion about the possibility of extending use outside BMW locations to airports, exhibition centers, major shopping centers and more.

Related Content

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MorePlant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

Read MoreJEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)