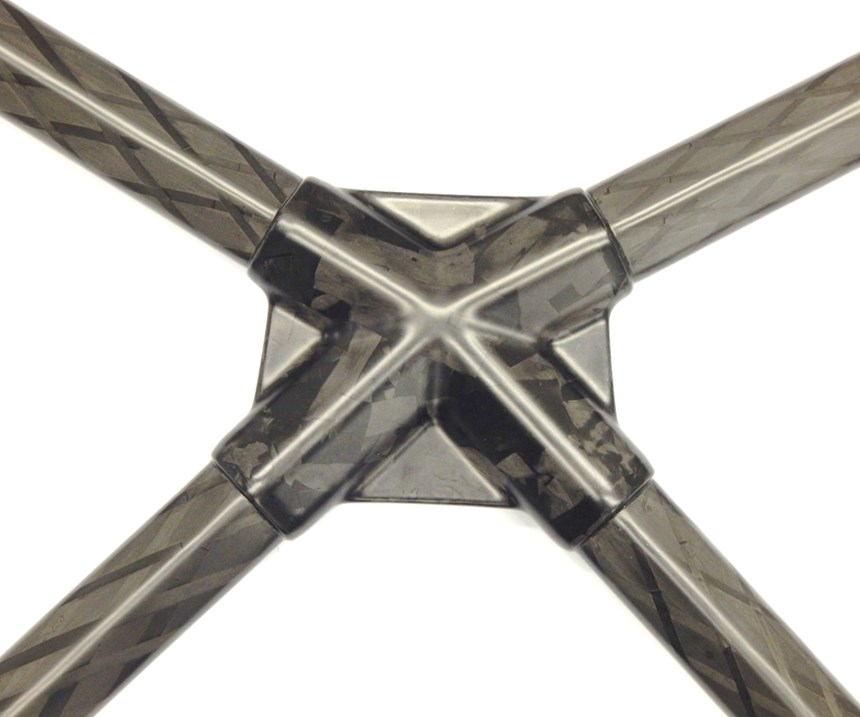

Multimaterial carbon fiber composite engine brace

The project’s aim was to produce a lighter, composite version of an aluminum Audi engine brace, with a more aesthetic molded shape.

HexMC from Hexcel (Stamford, Conn., U.S.), developed more than a decade ago, is a high-performance molding material that comprises chopped, randomly-oriented high-strength carbon fiber prepreg “chips” assembled into a mat-like material. The industrial version, trademarked HexMC-i 2000, is made with snap-curing HexPly M77 resin in a 2,000-gsm format for compression molding. According to the company, HexMC-i 2000 can produce complex 3D geometries and parts with varying thicknesses and is intended to bridge the price/performance gap between lower-cost sheet molding compound (SMC) and pricier, high-performance autoclave prepreg.

Hexcel’s automotive business unit was looking for a project that could demonstrate HexMC-i 2000’s performance, says Achim Fischereder, Hexcel’s director of sales and marketing for automotive. With a history of previous joint projects with Audi (Ingolstadt, Germany), Hexcel’s automotive business unit approached the OEM’s composites development team in early 2016 with the aim of qualifying the material into a production-ready manufacturing process. Audi was already evaluating carbon fiber SMC materials at the time and decided to assess HexMC-i 2000 as well. For the project, Audi selected the R8 engine bay brace, a cross-shaped component that braces the R8’s mid-mounted V10 engine, providing torsional stiffness to enhance driving dynamics. The project’s aim was to produce a lighter composite version of the existing aluminum part, with a more aesthetic molded shape.

Carbon fiber specialist Secar Technologie GmbH (Hönigsberg, Austria) joined the project, bringing its trademarked PulWinding process that effectively combines pultrusion with filament winding to produce high-torsion-strength, foam-cored carbon fiber profiles — the core is typically Rohacell PMI foam from Evonik Industries (Darmstadt, Germany). For the R8 brace, Secar produced shaped, foam-filled carbon fiber/epoxy tubes, which were then arranged in an X pattern and compression overmolded with HexMC-i 2000 to form the central “node” portion of the part. The opposite ends of the tubes were also overmolded to create attachment points to the car, with the metallic inserts molded in during the production process.

One of the toughest challenges was to achieve a good bond between the HexMC-i 2000 and the thin-walled (less than 1 millimeter wall thickness) carbon fiber tubes, without crushing the tubes. Ultimately the bond strength of the HexPly M77 resin system produced adhesion with no over-compression of the tubes; no adhesive film or additional bonding material was required between the tubes and the overmolded compound. The composite brace is reportedly 15 percent lighter than the aluminum version, and the random prepreg chips create an attractive surface, a key requirement of Audi’s development engineers. Following production of the first prototype parts at Secar, Audi subjected the component to static and dynamic load testing under room temperature as well as hot/wet conditions, and all test requirements were satisfied.

“We see a lot of applications where we can combine the impressive characteristics of HexMC-i with our innovative and high-performance Pulwinding and Pulbraiding technologies. This is a unique combination and a good answer to increased performance requirements in the automotive market,” says Werner Stoeger, sales and marketing director, Secar Technologie GmbH.

Related Content

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.