Near commercialization: CNT yarn, tape and sheet

Michael R. LeGault reports on progress toward first commercialization of carbon nanotube yarn-, tape- and sheet-type reinforcements for composites.

Since the discovery of carbon nanotubes (CNTs) in 1991, by Sumio Iigima of Nippon Electric Company Laboratories (now NEC Laboratories, Kawasaki, Japan), these nanomaterials have spawned much research and many start-up companies, and for good reason. CNTs are the strongest and stiffest materials yet discovered, and occur in two basic types: single-walled nanotubes (SWNTs), and the more easily constructed multi-walled nanotubes (MWNTs). And depending on the type and length, they can exhibit tensile strength 4 to 13 times greater than Kevlar and an elastic modulus from 5 to 20 times that of stainless steel (For background reading about nanotechnology and CNTs, see "Editor's Picks"). The materials also have excellent electrical and thermal properties. Yet, until recently, CNTs have found limited commercial application, primarily as an additive, to enhance tensile strength and stiffness in conventional carbon fiber-reinforced composites in specialty applications and as an additive to the graphite anode of lithium-ion batteries.

This is because the most common CNT manufacturing processes have generally produced short carbon nanotubes a few tens of microns in length, usually in the form of a powder, which is then added into a matrix resin at typical loadings of about 3 to 4 percent. Composites modified by this method have improved structural properties but less-than-ideal electrical and thermal properties because short nanotubes provide less continuity for the travel of electrons, which inhibits the conductivity of the composite. Longer nanotubes would enhance the conductivity of a composite, but the challenge has been the lack of a practical process to produce longer CNTs. Formed in 2004 as a spin-off of Synergy Innovations Inc., Nanocomp Technologies Inc. (Concord, N.H.) took up that challenge, hoping to expand the commercial use of CNTs in applications that require electrical and/or thermal conductivity.

Lengthy R&D

Nanocomp spent three years in R&D, perfecting its manufacturing process. Since 2007, it has been making SWNT and MWNT materials in its 11,000-ft2 (1,022m2) research facility in Concord and supplying them to prepreg manufacturers and other suppliers and contractors for testing and qualification.

The process involves two steps: the company’s patented carbon vapor deposition (CVD) method, which is used to assemble nanotubes (up to 1 mm/0.039 inch in length), coupled with its postprocessing manufacturing methods for using the longer CNTs to form yarns, tapes and sheets — forms already familiar to manufacturers of composite products.

The CVD method forms nanotubes from a three-component mixture of grain alcohol, an iron catalyst and a group of several critical but unspecified proprietary ingredients that are fed into the injector of a CVD furnace, according to John Dorr, Nanocomp’s business development manager. The vaporized mixture is transported through the furnace by a hydrogen carrier gas and heated to a high temperature, also proprietary. The nanotubes, which Dorr says resemble a cotton-candy-like cloud or aerogel, are harvested at the other end of the furnace and processed in one of two ways.

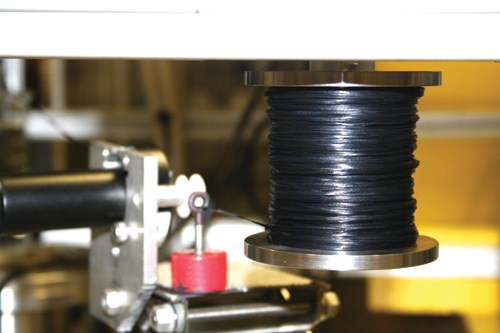

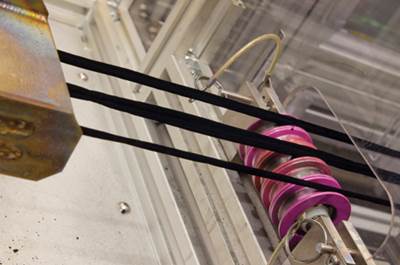

If yarn is to be produced, the CNT aerogel is collected continually on a rotating “anchor” at the end of the furnace. The next step uses a proprietary technique to pull off continuous strands of the material from the anchor and deposit them onto a rotating spool (see top photo, this page). Then, these thick strands are spun into a yarn approximately 20 to 30 microns in diameter.

In contrast to yarn, sheet is produced in a batch process. A production run of nanotubes is initiated and continues until the furnace system has produced a quantity of material sufficient to achieve the desired areal density. In this case, the material is harvested from the anchor and deposited onto a belt. The belt is then translated, or shifted, first to the left, then to the right, repeatedly. This process essentially compresses and folds layers of the material over one another — similar to the way in which phyllo dough is made — to produce a sheet of a desired thickness with dimensions up to 4 ft wide by 8 ft long (1.2m by 2.4m). The sheet can be seamed together to form long continuous rolls, if specified by a customer. The orientation of the sheet’s CNT fibers is isotropic.

At present, tape is produced as a by-product of the sheets, which are slit at various widths and seamed together at the ends. Dorr says the company will transition tape manufacturing to a continuous, automated process when fully commercial applications for the tape product arise.

The sheet is sold under the trade name EMSHIELD, and the yarn is sold as CTEX. The tape, which is relatively new, had not yet been given a trade name as this article went to press.

CNT-to-CNT connectivity

Nanocomp’s CNT-based composites have significantly better conductivity, compared to short-CNT filled composites, because its sheet-, yarn- and tape-forming processes “create the basis for a macro-structure composite — for example, a prepreg — that can give you 95 percent CNT out of the box,” according to Dorr. Nanocomp’s product forms exponentially increase tube-to-tube connectivity within the composite matrix. Nanocomp’s sheet, yarn and tape reportedly have electrical and thermal conductivity comparable to copper on a per weight basis. As a result, the materials are significantly more conductive than conventional carbon fiber composites. Likewise, Dorr reports that the application of a single 10-g/m2 CNT sheet to a carbon fiber prepreg will reduce surface resistivity of the composite by an order of magnitude or more.

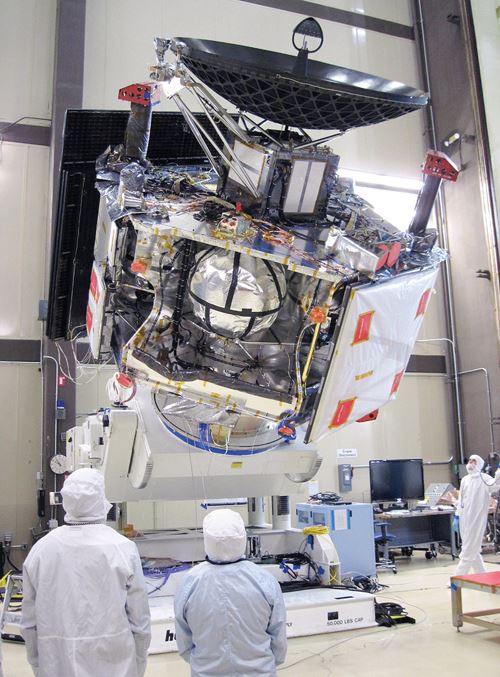

For this reason, Dorr notes, the company’s first commercial applications for its CNT-based products will likely be substitutes for metals in electrical and thermal parts, and components in aerospace applications where the materials’ low weight — less than half that of aluminum — will offer significant payload advantages. The company’s CNT sheet, EMSHIELD, was incorporated as a surface layer on several critical components of NASA’s Juno spacecraft, launched in August 2011, to provide protection against electrostatic discharge (see opening photo). In addition to electromagnetic interference (EMI) shielding applications, Dorr also foresees opportunities to use the sheet product as panels or parts for convective generation of heat in satellites, aircraft and, perhaps, automobiles. One especially promising potential application is in the cowling of jet engines. A CNT-based composite cowl could be electrically heated, eliminating the need to recirculate bypass engine heat to prevent engine icing and, in the process, increase engine efficiency.

The high CNT purity of the end product also reduces cost because Nanocomp’s methods eliminate the expensive postgrowth purification steps other manufacturers reportedly have had to use to achieve high purity. And Nanocomp’s nanotube-based materials exhibit improved flexural properties compared to conventional carbon fiber and metals. “Our materials can be flexed and bent millions of times and not break,” Dorr claims, noting that the U.S. Department of Defense (DoD) has provided funding for R&D to incorporate CNT-based composites in antiballistic applications, such as body and vehicle armor. The overall goal of the program is to create lighter armor solutions with antiballistic capability equal to or better than the material they replace, using either uniform CNT composites or hybrids of CNTs and other materials.

Porosity and processing

Because the company’s CNT materials have inherently lower porosity than most carbon-fiber fabrics, one of the ongoing challenges to full commercialization is adapting current processing technologies and resin systems for use with CNTs to enable efficient manufacturing of composites. Dorr says the materials can be processed via autoclave with a variety of off-the-shelf prepreg resins, such as bismaleimides (BMIs) and cyanate esters, but the temperature, pressure and ramp-up rates are different than those used to process conventional carbon fiber prepregs and fabrics. In general, higher pressures and temperatures are required. Further, Dorr reports, “lower viscosity resins are going to be more friendly for the porosity morphology of our material.”

The remaining challenges notwithstanding, the DoD, through its Title III Defense Protection Act, has designated CNTs as critical to national defense and, thanks in part to a DoD grant, Nanocomp will open a commercial-scale 100,000-ft2 (9,210m2) facility in Merrimack, N.H., early this year.

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreRead Next

Nanotechnology: Into the realm of real

Fast, scalable process grows nanostructures directly on composite reinforcements for a “drop-in” use in volume production processes.

Read MoreCNTs ride a rising tide of nanotech optimism

Dr. Louis Pilato offers facts, figures and comment on the growing utility of carbon nanotechnologies in composites applications.

Read MoreNanotechnology: It's real

CompositesWorld's conference director Scott Stephenson reviews several recent conference presentations as evidence that nanocomposites are no longer just the stuff of dreams.

Read More