New Bridge Deck Bests Early FRP Systems

Mechanically fastened, two-piece composite deck system addresses challenges inherent in previous fiber-reinforced polymer deck designs, lowering cost, speeding installation and reducing maintenance.

When the I-35W Bridge collapsed in Minneapolis during the evening rush hour on Aug. 1, 2007, killing 13 and injuring 145, the public learned what civil engineers have warned for decades: Bridges built 50 or more years ago during America's interstate-highway boom are aging, and many are operating beyond their designed life expectancy and weight limits. An American Society of Civil Engineers (Reston, Va.) study says that more than a quarter of the 600,000 U.S. bridges are functionally obsolete (no longer up to standard for current traffic demands) or structurally deficient (one or more bridge components has deteriorated), and it will take $1.6 trillion (USD) and five years to fix them with conventional concrete and steel. Deteriorating bridge decks are one cause of these poor ratings.

Searching for faster and less-costly methods of upgrading infrastructure, the U.S. Federal Highway Admin. (FHWA) has encouraged development of prefabricated bridge components, such as decks. Prefabrication speeds new construction or repair, reduces installation labor costs, facilitates construction on difficult sites, improves quality control and component consistency, and reduces traffic shutdown/slowdown, which — on congested highways — can represent 30 to 50 percent of total bridge construction costs.

Composites vs. traditional steel and concrete

To date, most prefabricated bridge decks have used prestressed concrete or open-steel-grid systems. Both are proven technologies, but each has problems.

Prestressed concrete is heavy and therefore difficult to transport and install. Its high specific gravity translates to significant "dead weight," reducing a bridge's true carrying capacity. Furthermore, prestressed concrete is becoming increasingly expensive and — like poured concrete — is prone to spalling and cracking. This exposes reinforcing rebar to corrosion, necessitating regular maintenance and limiting the bridge's service life. Open-steel-grid decks, used on moveable bridges, corrode quickly, require significant, frequent and costly maintenance, and have even shorter life expectancies (typically only 10 years). Moreover, they provide a noisy, slippery driving surface because the grid provides less contact with tires than solid surfaces do.

Composite decks, first used for U.S. bridge construction during the early 1990s, addressed some of these issues. Made with lightweight, corrosion-resistant materials, they increased carrying capacity for a given design, improved worker safety and reduced transportation and installation costs because components were easier to move. When covered with a wear surface, they also provided significantly longer use life, making them cost-competitive when true lifecycle costs were calculated. Today, the U.S. has 120 such decks in service.

Unfortunately, first-generation composite decks presented challenges, too. In many cases, costs ran higher than projected. There were installation problems because structural adhesives, used to join deck components, couldn't be used in cold, wet weather. Also, because fiber-reinforced polymer (FRP) deck components used solid or sandwich-panel composites, connecting parts to clips or studs on the bridge superstructure was difficult because installers, unable to see through or around them easily, were drilling holes for attachments "blind."

Building a better composite bridge deck

When Dan Richards, Ph.D., P.E., a retired aerospace engineer with a background in composites, went to work for a composite deck manufacturer, he soon understood why adhesive fasteners and solid-section bridge deck components were making installation a challenge for workers. After his employer showed no interest in making design changes, Richards took his ideas home to the family farm in Virginia, where he invented and patented a new structural composite deck design in 2002. After successfully testing prototypes at the Construction Facilities Laboratory at North Carolina State University (Raleigh, N.C.), Dan and his wife, Meg Goodman Richards, founded ZellComp Inc. (Durham, N.C.) and began commercial production of prefabricated composite bridge components in 2005, with their first installation in 2006.

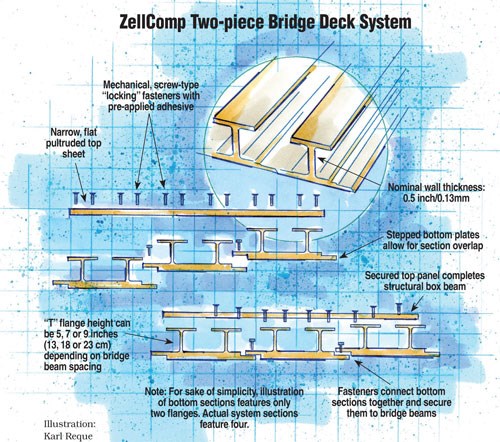

Like earlier composite decks, ZellComp's system uses pultruded composites because the continuous-glass reinforcement produces extremely stiff but lightweight, corrosion-resistant parts. However, unlike previous solid or sandwich-panel designs, Richards' is a two-piece system. Its foundation is a complex asymmetrically shaped bottom section that features a flat plate with four T-section "flanges" standing off the surface and running the length of each section (see illustration, top right). Flange depth is available in three standard sizes: 5, 7 and 9 inches (13, 18 and 23 cm). The greater the spacing between the bridge's beams, the deeper the flange specified for that bridge. Profiles are pultruded to lengths that correspond to the width of a given bridge.

At the job site, bottom sections are laid perpendicular to traffic and tied to the bridge's superstructure (typically concrete or steel beams) with either shear studs or structural clips. Bottom section profile walls are fairly thin (0.5 inches/0.13 mm). The open design of the ZellComp system allows installers to more easily see where to drill holes to make these attachments, thus avoiding the blind attachments of earlier systems. Bottom sections are tied to each other via lap joints and mechanical fasteners, which allow fast attachment regardless of weather conditions and also transfer some shear during use. Although extensive fatigue testing has never shown screws to back out of this system, as an extra measure of safety, ZellComp's fastener manufacturer provides screws with a pre-applied epoxy spray adhesive sourced from ND Industries (Clawson, Mich.). As the fasteners are seated in the composite sections (with or without predrilling a pilot hole), the pressure-activated adhesive helps lock the fastener to the composite. Should a deck section require subsequent repair, however, ZellComp says the screws can be driven back out of the composite components.

Over the bottom sections, ZellComp places long, flat, narrow pultruded top sheets (typically 20 ft by 4 ft by 0.5 inches/6m by 10 cm by 13 mm). Laid parallel to traffic, the panels are affixed to bottom sections with the same locking fasteners (with or without pilot holes) driven through the top sheet into the T-shaped flanges on bottom sections. The result is a box-beam structure that is mechanically efficient yet lightweight and easy to work around.

Given the complexity of the bottom profile, ZellComp wanted to work with an experienced pultruder and therefore selected Creative Pultrusions Inc. (CPI, Alum Bank, Pa.) to manufacture both top and bottom sections from unsaturated polyester (Reichhold Inc., Research Triangle Park, N.C.) and continuous E-glass (PPG Industries, Pittsburgh, Pa.). CPI developed the resin/glass formulation to meet ZellComp's specifications and uses a high-pressure injection die to produce the components because it enables them to achieve a high fiber volume fraction of about 50 percent.

When bottom and top sections are fully secured, one of three types of wear surface is applied over the deck — polymer concrete (typically a methacrylate/epoxy system from Benicia, Calif-based Kwik Bond Polymers Inc.) or an epoxy system (provided by either POLY-CARB Inc. of Solon, Ohio or Transpo-Industries Inc. of New Rochelle, N.Y.) or asphalt. In contrast to the 4-inch/10-cm layer of asphalt or concrete used on typical bridge decks, a mere 0.5-inch/13-mm (or less) of wear layer is used, yet it offers longer service life because the wear surface material is more flexible than steel or conventional concrete, and it is also immune to rust and spalling. (Notably, California's Department of Transportation installs polymer concrete wear surfaces over concrete bridge decks to extend their service life.) Additionally, the polymer concrete provides a quieter and less slippery ride than open-steel-grid because the solid surface provides better contact with tires. While the top surface of all composite decks must be sanded prior to application of the wear surface for better adhesion, a task generally done at the work site, ZellComp's top panels can be sanded prior to shipping to speed installation.

To date, the company has completed decks on two bridges, one on Tangier Island, Va., in the Chesapeake Bay (November 2006) and the other in Bradford, Vt. (November 2007). New decks will be installed early in 2009 in Indiana and Florida; the latter will replace an open-steel-grid deck on a moveable bridge. ZellComp expects that open-steel-grid deck replacement will become a significant new market for its system.

The results so far are impressive: ZellComp's technology weighs 75 to 80 percent less than prestressed concrete. It offers roughly double the service life of poured or prestressed concrete (75 vs. 30 to 40 years) and more than seven times that of open-grid steel. The decks install about as quickly as open steel and prestressed concrete- typically two days — and much faster and more easily than poured concrete, which requires from 14 to 28 days, assuming favorable weather during construction. The upfront cost of a ZellComp deck — even at startup production volumes — is, according to the company, significantly lower than earlier pultruded systems, comparable to that of steel decks and only 20 to 25 percent more than concrete for nonmoveable bridges. However, when labor and downtime savings, reduced maintenance and longer service life are factored in, a lifecycle analysis reveals that ZellComp bridge decks are extremely cost-effective. As demand for these systems rises, ZellComp expects that production costs will drop significantly, making the decks even more competitive.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreRead Next

Are Hybrid Designs the Future for Composite Bridge Decks?

Teaming composites with traditional materials may be the future direction for cost-effective infrastructure replacement.

Read MoreBuilding Bridges to Bridge and Building Rehab Markets

Despite a lack of standardization and education in the civil construction sector, these innovators use carbon and steel fibers to reinforce the business case for composites.

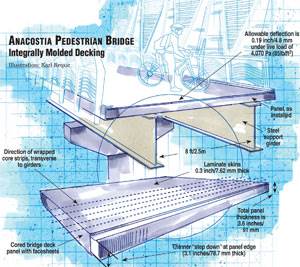

Read MoreEngineering Insights: Pedestrian Bridge Makes Case for Composites

Infusion molded deck incorporates high-performance core, which facilitates fast processing.

Read More

.jpg;width=70;height=70;mode=crop)