Opportunities for composites at AIA 2015

Key trends and new products on the floor at this year's American Institute of Architects show.

|

|

The Composite Pavilion at the 2015 AIA Expo featured Justin Diles' winning concept in composites "Plastic Stereotomy". SOURCE: CW, Justin Diles.

This was the second year for the Composites Pavilion at the AIA show — the annual conference of the American Institute of Architects (AIA Expo, May 14-16, Atlanta, GA, US). Sponsored again by the Architectural Division of the American Composites Manufacturers Association (ACMA, Arlington, VA, US), this year’s pavilion featured over 20 exhibiting companies and the striking “Plastic Stereotomy” composite structure in the CompositeBuild.com area.

Designed and built by Justin Diles, assistant professor at Ohio State University’s (OSU) Knowlton School of Architecture (KSA, Columbus, OH, US), “Plastic Stereotomy” won the 2015 TEX-FAB competition, selected from a field of 70 entries to demonstrate how the latest digital design and fabrication technologies in architecture, engineering and construction (AEC) can be realized using fiber-reinforced composite materials.

Just as it has revolutionized structures in the aerospace, automotive and many other industries, digital design is similarly enabling new levels of performance and efficiency in building structures. An example of this drive for performance and another key trend where composites are gaining traction is thermal bridging and thermal breaking. Thermal bridging is when poor thermal insulators — like steel and aluminum — are in contact throughout a building envelope from its interior to its exterior. Heat and cold are thus easily conducted in and out of the building, which defeats insulation and reduces energy efficiency. Thermal breaking is the practice of installing a break in this conductive path, such as using an air gap or insulating materials like plastics or composites.

|

|

INNERGY products use pultruded glass fiber-reinforced polyurethane resin to achieve higher thernal performance vs. aluminum in window lineals for multi-story buildings.

SOURCE: CW, Deceuninck

INNERGY Rigid Thermal Reinforcements are pultruded glass fiber-reinforced composite inserts manufactured by Deceuninck (Monroe, OH, US). They are designed to improve window thermal performance by eliminating the thermal bridge that exists with current aluminum inserts. INNERGY products replace aluminum inserts, sliding easily into aluminum window frames to provide support and insulation. Claiming thermal performance 700 times better than aluminum, the INNERGY product line was developed in cooperation wtih Bayer MaterialScience LLC (Pittsburgh, PA, US) and uses its polyurethane resin that is 20% bio-based.

Going even further is Advanced Architectural Products’ (AAP, Allegan, MI, US) SMARTci system, where “ci” stands for continuous insulation. SMARTci comprises GreenGirt composite girt/attachment members, insulation and an engineered installation package. A girt is a horizontal structural member in a framed wall used primarily to provide lateral support to columns and posts against wind loads. Traditional steel and aluminum girts are major causes of thermal bridging. GreenGirt uses bioresin and recycled glass materials. The SMARTci system is also recyclable, helping buildings to meet LEED certification. (LEED ratings are awarded by the Leadership in Energy and Environmental Design (LEED) certification program.)

Not only does this system eliminate thermal bridging, it is not susceptible to moisture, corrosion or electrochemical reactions. It also eliminates cold spots which cause condensation that leads to moisture and mold issues, and SMARTci has fewer parts than most systems, enabling quick installation. AAP claims that SMARTci can save millions of dollars in heating and cooling costs depending on the building size and application. The products have also passed Class 1 fire tests including UL94 V0 and ASTM E84 ratings.

According to Bayer MateralScience personnel involved in the development of INNERGY, the push for higher thermal performance in buildings has revealed lineals as the weak link. Residential construction uses vinyl without reinforcement, but this lacks enough load-carrying capacity for multi-story buildings. Thus, fiber-reinforced composites have an opportunity.

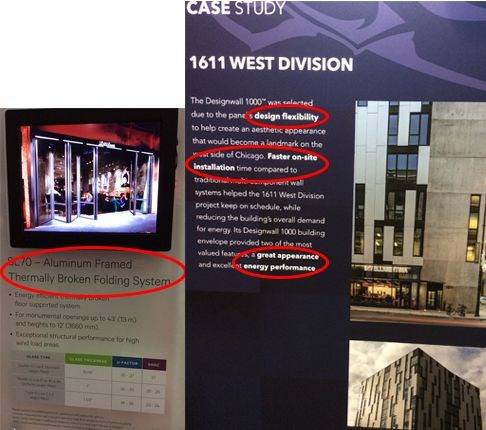

Thermal breaks were, in fact, one of the larger trends at AIA 2015. Other trends that favor composites include:

- Faster on-site installation — lighter weight materials and off-site fabricated and integrated assemblies that can be easily transported and erected.

- Design flexibility — the ability to accommodate different shapes and building methods.

- Sustainable buildings.

Trends on the floor at the 2015 AIA Expo. SOURCE: CW

Hydrophilic Tile (HT) coated ceramic achieves energy efficiency using environmentally-friendly materials but without causing issues with moss, algae and mold. The supplier, AGROB BUCHTAL (Buchtal, Switzerland) claims that this coating will actually break down pollutants, such as industrial smog and car fumes. SOURCE: CW.

Another interesting development is in the large, high volume low speed (HVLS) air circulation fans used in commercial buildings and warehouses. Many of these have adopted winglets and kinked blades, similar to the latest advances in helicopter rotor blades. Different manufacturers debate how much these actually help to increase efficiency and reduce motor size and energy consumption. But it is still interesting to see something so immediately identifiable as an aerospace technology hanging from a ceiling and being marketed by an industry we typically think of as static and slow to innovate.

|

|

|

Winglets, kinked blade tips and patented airfoils are standard in high volume low speed (HVLS) fans for commercial and industrial buildings.

SOURCE: Serco Entrematic, Kelley Fans and Big Ass Fans.

New to the composites pavilion this year, PolyStrand (Englewood, CO, US) highlighted its recyclable, fire-retardant composite panels, offering lightweight, high-strength and impact resistance for interior structures and dividers. The glass fiber-reinforced polyethylene terephthalate (PET) surfaces are paintable and bondable, including inline adhesion of custom finishes like woodgrain, nonwoven, carpet and linen facings. The company also has the ability to make very large panels, up to 10 ft wide, 6 inches thick, and any length using one of the world’s largest lamination machines.

Crane Composites (Channahon, IL, US) discussed its new line of designer finishes, including the ability to customize composite panels with specific designs, like the basketball scenes imprinted on FRP panels supplied for a new concessions area in the University of Michigan’s Crisler Center. The company has recently completed another customized panel system for Texas A&M University.

|

|

Longtime supplier of FRP panels for cleanrooms, restaurants and restrooms, Crane Composites is moving into new applications with designer finishes and custom imprints (right). SOURCE: Crane Composites.

Related Content

Swedish parking garage to incorporate decommissioned wind blades

Architect Jonas Lloyd is working with Vattenfall to design the multistory building with a wind blade façade, targeting eco-friendly buildings and creative ways to remove blades from landfills.

Read MoreCCG meets customer demand with StormStrong utility pole lineup

Additional diameters build on the portfolio of resilient FRP pole structures for distribution and light pole customers.

Read MoreComposites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

Read MoreSGL Carbon carbon fiber enables German road bridge milestone

A 64-meter road bridge installed with carbon fiber reinforcement is said to feature a first in modern European bridge construction, in addition to reducing construction costs and CO2 emissions.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More