Out-of-autoclave processing: <1% void content?

Research sheds light on air and air-bubble behavior in OOA aerospace prepregs.

The autoclave is, perhaps, the most beloved and most maligned piece of equipment employed in the fabrication of composite aerostructures. It is beloved because, when used properly, it brings to bear on a carbon fiber laminate the brute force required to compress to a very small and harmless size the entrapped air and volatile gases that form voids in cured resin that otherwise would be problematic in a finished composite part. It is maligned, however, because the application of that brute force costs dearly — in capital, energy and time. Composites fabricators in aerospace and other large industries, such as automotive and wind energy, therefore, are in search of out-of-autoclave (OOA) manufacturing processes that can cross the mandated 1% void content threshold with less expensive, more efficient equipment yet achieve autoclave-quality composite parts for critical structural applications. When it comes to the aerospace sector, however, OOA usually means vacuum-bag consolidation of carbon fiber prepregs, followed by oven cure.

The term OOA implies that the process is simply a non-autoclave version of the autoclave-based original. Indeed, OOA processing is attractive because it offers a more sustainable manufacturing pathway, based on the cost savings that accrue when foregoing the use of the autoclave, while producing autoclave-quality composites. But OOA processing of aerostructures forces the fabricator to cope with variables that were, for the most part, obviated by the use of the autoclave. And variable numbers one and two are entrapped air and air bubbles, the mismanagement of which can quickly turn a carbon fiber laminate into an expensive, void-filled, out-of-compliance paperweight.

Managing air and bubbles, however, requires some understanding of air and bubble behavior, and such understanding is in limited supply in the composites industry. It is, however, the focus of in-depth experimental work by the University of Delaware (UD, Newark, DE, US), where researchers are trying to shed some light on how air, resin and fibers interact during vacuum-based manufacturing — and the conditions under which air and air bubbles are most likely to escape before resin cure is complete. The work, it is hoped, will help OOA processors more easily achieve <1% void content.

The research team at UD is led by Dr. Suresh Advani, George W. Laird professor and department chair of mechanical engineering and associate director of the university’s Center for Composites Materials. He was assisted by Ph.D graduate candidate Tom Cender, Dr. John Gangloff (then a Ph.D. candidate, now a Science and Technology Policy Fellow at the U.S. Department of Energy – Fuel Cell Technologies Office) and Dr. Pavel Simacek, a research scientist at the Center. Assistance regarding bubble behavior was provided by Dr. Volkan Eskizeybek, assistant professor at the Department of Materials Science and Engineering, Çanakkale Onsekiz Mart University (Çanakkale, Turkey). Cender first reported on the group’s work in a paper presented at SAMPE 2014 (Seattle, WA, US) titled, “Void reduction during out-of-autoclave thermoset prepreg composite processing.”

Full prepreg vs. semi-preg

OOA manufacturing using a vacuum-based process is typically done with a fully impregnated fiber reinforcement. However, without the heft of an autoclave, special care must be taken to manage air and void evacuation, and this is typically done with a semi-permeable layer of some sort. Alternatively, a fabricator can choose to use a fiber reinforcement that is partially impregnated (a semi-preg) with a resin in film form. The partial impregnation allows air and voids to escape the fabric as vacuum is drawn, before full consolidation is complete.

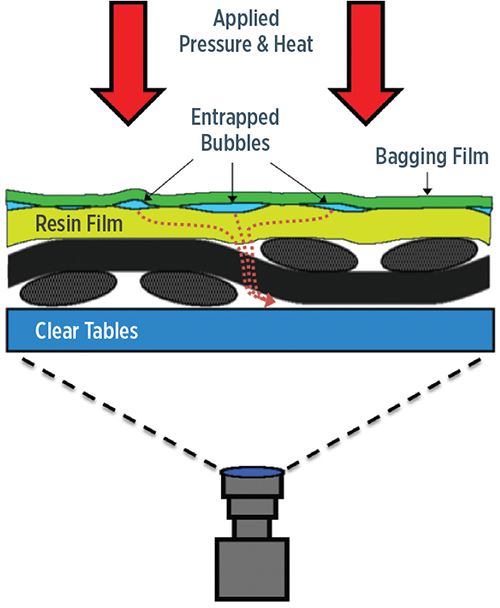

It’s on semi-preg technology that the UD team has focused, evaluating the use of resin film with, initially, 2x2 twill fabric. Specifically, the team is evaluating the relationship between various levels of impregnation of the resin film in OOA semi-pregs and the utility of intra- and inter-fiber pathways for evacuation of gasses that are trapped in the laminate before consolidation and cure (see Fig. 1).

“One difficulty in qualifying new OOA prepregs is the wide range of available choices. The distribution of resin — with respect to the dry areas of the prepreg — can be configured in different ways, depending on the supplier,” says the report. In short, there is not yet a defined level of OOA prepreg impregnation that is considered optimum for effective gas evacuation. “The goal of this work is to characterize and model the flow processes associated with partially impregnated prepregs.”

The experiments used three prepreg types:

- Gurit ST94 RC200T, 200 g/m2, 3K tow, 2x2 twill, 42% resin, by weight.

- Gurit ST94 RC303T, 303 g/m2, 12K tow, 2x2 twill, 42% resin, by weight.

- Cytec (formerly ACG) VTM264 CF0100, 283 g/m2, 3K tow, 4x4 twill, 43% resin, by weight.

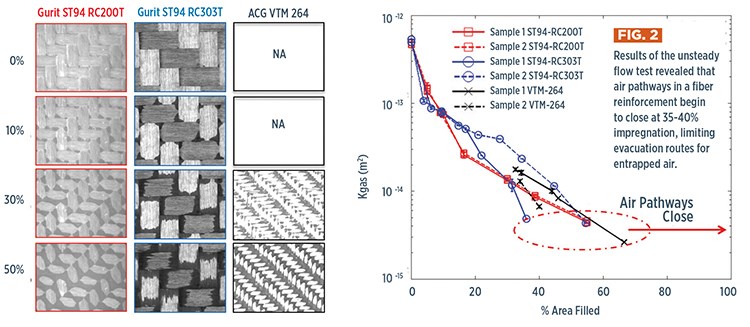

Resin is distributed as a film on each twill type and compressed with a consolidation block at 55°C onto and into the fabric to a variety of impregnation percentages: 0%, 5%, 10%, 20%, 30%, 40%, 50%, 70% and 90%. To halt resin flow at the desired impregnation state, the laminate is immediately cooled with ice water over the vacuum bag. With the resin immobilized, the prepreg’s permeability is assessed, using what is called the unsteady flow test, which measures pressure drop in a laminate over a given time period.

Fig. 2 shows the results of this test, which indicate that air pathways in the fiber reinforcement begin to close at >75% impregnation (as measured by surface area of impregnated fibers). As pathways close, it becomes much more difficult to evacuate gases and, thus, increases the likelihood of trapped gases becoming bubbles and hardening, during cure, into voids. “Once the inter-tow regions are saturated, any further resin impregnation into the fiber tows results in a linear decrease in the laminate’s permeability to air,” says the paper.

Gangloff notes, “In traditional composites processes, such as resin transfer molding [RTM], a dry fiber bed is impregnated with liquid resin. The goal is to direct the incompressible resin into all the dry fiber areas for complete saturation. In OOA processes, the prepreg is, typically, partially saturated and is complicated by air trapped between prepreg laminates. This air must be evacuated for full resin saturation. Lack of process understanding has made the edge and through-thickness breathing dominated by trial-and-error and very expensive.”

If vacuum is not suffiently achieved inside the laminate’s air pathways, gases will inevitably become trapped and manifest as voids. By coupling the technique for monitoring resin saturation with the technique for measuring air permeability, the required vacuum dwell time can be reliably predicted for a given prepreg and part geometry.

Gangloff notes, “When probing the multiphase flow of bubbles and resin together through the tortuous flow pathways in OOA fabrics, more detailed fluid flow modeling is necessary to determine if moving bubbles in moving resin can navigate and escape prepregs during processing before resin cure.”

Bubble behavior

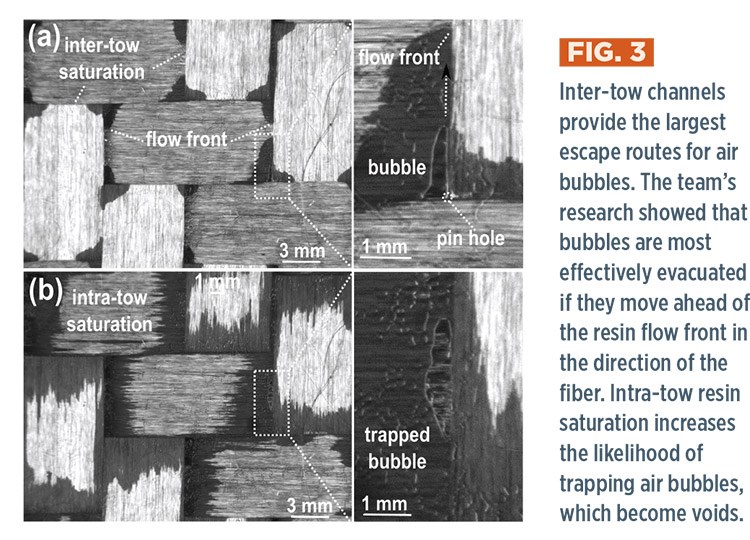

“The most important aspect of the group’s work has been just the documentation of bubble behavior under vacuum,” Cender reports. Still images and video of bubble development and movement have proved valuable in understanding what conditions facilitate bubble migration, and what conditions hinder it (Figs. 2 & 3).

“We experimentally observe bubbles moving two to four times faster than the resin flow — in the channels between fiber tows, specifically, the undulations of the fabric,” Cender reports. “This makes it possible for bubbles to reach the flow front and be vented from the laminate. We also make note of conditions under which the bubbles will become stuck in the laminate. Bubbles often do not break [free] once the resin fills these inter-tow channels. If a bubble can penetrate the fiber tow, it always moves in the longitudinal direction — with the fibers. Bubbles never penetrate fiber tows in the transverse direction — across the fibers.”

Although Cender’s work on bubble mobility is ongoing, he says results, thus far, indicate that an OOA semi-preg should have an initial resin fraction of not more than 30%. If initial impregnation is more than 30%, says the paper, it “will take longer to de-gas the laminate and does not allow enough space for resin flow inside channels (inter-tow spaces) for voids to reach the resin flow front.”

Looking ahead, says Advani, more work needs to be done to understand what variables enhance bubble mobility. Large bubbles move faster than small bubbles, he says, and resin viscosity and surface tension play obvious and important roles. Experiments will further evaluate the roles of tow size, channel size, fabric architecture and rate of vacuum pull in minimizing OOA void content. “One thing we know,” says Advani, “is that if we can get the bubble to the front of the flow front, it’s much easier to move it.”

Ultimately, says Cender, he’d like to develop impregnation data for a variety of fiber forms that prepreg suppliers can use to optimize the products they provide to OOA fabricators. In any case, he says he wants to bring a greater level of understanding and sophistication to OOA molding: “We want to dismiss the misconception that if you apply vacuum to your laminate, that the bubbles will always reach air pathways and be vented from the system. Bubbles can still get stuck if the impregnation is too high, no matter how long the vacuum dwell is held.”

Bubble behavior videos taken by Advani’s team are available on the CW YouTube page | short.compositesworld.com/Bubbles.

Related Content

SmartValves offer improvements over traditional vacuum bag ports

Developed to resolve tilting and close-off issues, SmartValves eliminate cutting through vacuum bags while offering reduced process time and maintenance.

Read MoreCompPair adds swift prepreg line to HealTech Standard product family

The HealTech Standard product family from CompPair has been expanded with the addition of CS02, a swift prepreg line.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More