Plant Tour: Fraunhofer ICT, Pfinztal, Germany

This wide-ranging research center works with government and industry to develop the best of polymer composite processing, across a range of technologies.

Fraunhofer-Gesellschaft (Munich, Germany) is the largest applied research organization in Europe, staffed by 24,500 people, mostly scientists and engineers. More than 70% of the group’s annual budget, which tops €2 billion (US$2.35 billion), comes from contract research with industry and publicly financed research projects, covering the gamut of scientific topics. Yet, despite its scale, this massive organization is unobtrusive. Its more than 65 institutes and research units dispersed throughout Germany, and the 34 additional research units located beyond those borders are, typically, located a bit off the beaten path.

Such is the case with Fraunhofer Institut für Chemische (Fraunhofer Institute for Chemical Technology (ICT). Found in southwestern Germany, within the state of Baden-Württemberg and a short distance east of Karlsruhe, a city on the Rhine and the home of the Karlsruhe Institute of Technology (KIT, which maintains a close relationship with Fraunhofer), ICT comprises a sprawling collection of buildings, old and new, on a steep hillside above the small village of Pfinztal. Surrounded by forest and farmland, ICT was founded in 1959 as the Institute for Chemical Propellants. It was originally located nearby in an abandoned stone quarry that helped contain its rocket combustion experiments. In 1964, operations were moved to the current site and assigned the current name. The 1970s brought contract research from civil and military customers, and polymer engineering was added to the research portfolio in 1994. Today, ICT employs more than 500 people and has a yearly turnover of €36.5 million (US$40 million).

ICT’s active polymer engineering department includes within its purview high-performance fiber composites, nanocomposites, thermoplastic processing, thermoset processing, microwave and plasma heating technology, foams and compounding/extrusion, all under the direction of department head and ICT deputy director Dr. Frank Henning. And despite its bucolic location, the activities and research projects there, as CW has reported over the years, have had far-reaching impacts throughout the world of composites. CW’s recent stop in rural Pfinztal to see, first hand, where such impact had its genesis, uncovered a rich scientific heritage.

Bilateral connections

The tour starts at the gate house where directions are given to Building 90, located about a half-mile distant, and further uphill. Luckily, fair weather makes for an enjoyable hike to the large, multi-story building that houses much of ICT’s composites-related activities. There, Alexander Roch, the head of ICT’s thermoplastic technology “corridor” within polymer engineering, clarifies that there are five main research centers on the campus: Two, involving energetic materials, work mainly (but not exclusively) for the German Ministry of Defense, leaving polymers engineering, environmental engineering (which includes recycling studies and weathering, among other topics) and applied electrochemistry (focused on batteries and fuel cells).

One-third of ICT’s budget, he says, comes from the German state, another third from industrial partners who contract research, and the final third from European Union and public German grants. Roch names, as an example of an applied electrochemistry project, the RedoxWind energy accumulation system, designed to test electrical storage of wind energy, and points out workers who are installing a large wind turbine tower and rotor on the ICT site to test the concept.

“Within the polymer engineering department, we cultivate very strong collaborations with automotive OEMs and Tier 1 suppliers,” states Roch. “Our location in Baden-Württemberg, with an established industrial base, puts us close to Porsche, Diamler and Mercedes-Benz as well as Audi.” He adds that the “bilateral connections” between Fraunhofer and its industrial partners are strictly confidential, and are structured such that OEMs pay for machine time, testing and consultations with Institute staff. Close relationships also have been established with machine and system suppliers, including Krauss-Maffei (Munich, Germany) and Dieffenbacher (Eppingen, Germany), that enable financial arrangements to ensure the best equipment for research. “We are not allowed to make parts for profit, only for prototyping and validation,” he explains.

Glass-shelved display cases in Building 90’s atrium show the wide range of ICT’s activities. Roch points out examples of automotive engine parts made using ICT’s thermoset injection molding process, a project undertaken with SBHPP, the high-performance business unit of Sumitomo Bakelite North America Inc. (Tokyo, Japan). An engine cylinder liner was injection molded with SBHPP’s glass fiber-reinforced phenolic (55% fiber content) pourable molding granules, with a cycle time as low as 45 seconds (see Composite engine piston cylinder housings). Also on display are long-fiber injection molded parts made with polyurethane resin composite parts made from bio-resins as well as bio-based fibers, and complex ribbed parts made using Dieffenbacher’s RELAY technology (developed originally by FiberForge, see Fiberforge places RELAY station with Fraunhofer ICT) that have been subsequently overmolded via injection molding. Roch shows parts made in a process that he has helped pioneer, as reported by CW: A thermoplastic in-mold foaming technology, combined with a controlled mold-opening technique called “breathing mold,” produces a foamed core between solid faceskins — both reinforced with chopped glass fibers. The part is formed in a single shot . Roch then leads the way to ICT’s variety of laboratories and work areas to show how these innovative materials and processes are realized.

An array of polymer processes

The first stop, only steps away from the atrium, is the compounding and foam shop. Here, workers are experimenting with extrusion of foam profiles and shapes, derived from neat resin pellets. “We’re researching materials from commodity plastics through engineering resins to high-performance plastics, as well as the process itself, using a twin-screw extruder,” says Roch. “In particular, we’re looking at a range of particle foams, including bio-based foams, and experimenting with beads with tailored properties and sizes, and better ways of molding.” The polymer beads undergo pre-treatment, including pressure loading and prefoaming, then are processed in a laboratory-scale “steam chest” molding machine that welds the foamed beads together — the most common example of such a process is the Styrofoam cup. Roch says the lab-scale machine allows production of samples with precise densities for testing, for example, mechanical and thermal properties or weldability, for industrial and consumer applications. A larger steam chest molding machine from Erlenbach Gmbh (Lautert, Germany) is used for part production. He shows two examples: A molded particle bio-based foam bicycle helmet prototype and a shape that could be used for an automotive visor application. Many market-oriented particle foam projects are ongoing, including creating tailored polymer combinations in a single part, dosing to create larger foam particles, as well as combinations of polymers with metal foams. Additionally, foamed profiles are being extruded as part of a study for a confidential client. They will be trialed as insulation panels for the construction industry.

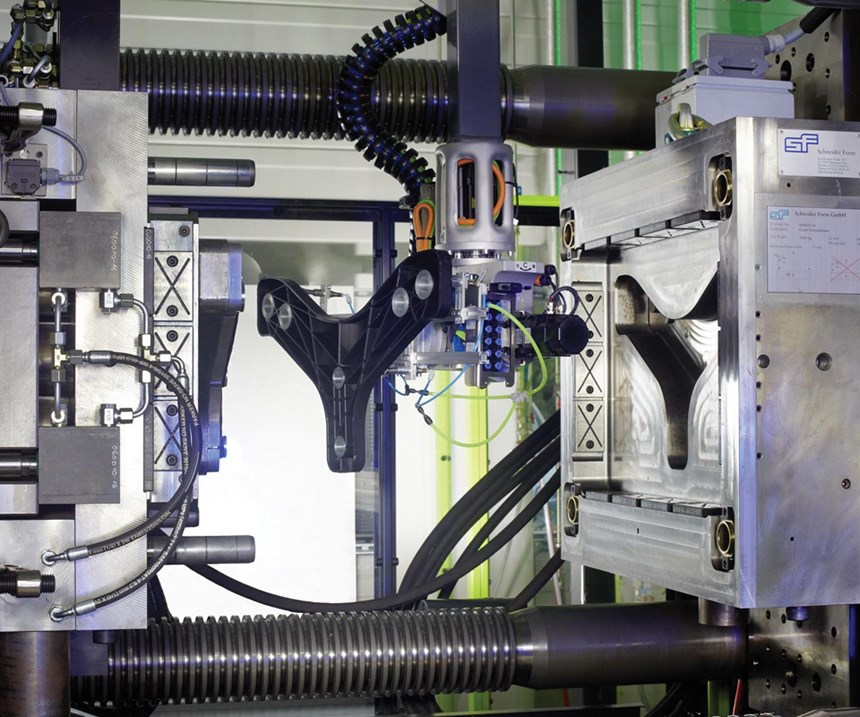

The adjacent, spacious work area is dedicated to research and optimization of injection molding processes, and particularly, long-fiber injection molding (long fiber-reinforced thermoplastics or LFRT), foam injection molding (FIM) as well as thermoset injection molding using thermoset granules. Roch shows ICT’s newest machine from KraussMaffei, a multifunctional GX Series machine capable of all three molding processes. Technicians test the control system as Roch demonstrates how injection unit barrels can be swapped out in modular fashion, to accommodate different polymers and chopped fiber lengths: “We have a special screw for molding the phenolic thermoset granules.” A robot eventually will be integrated into the machine for material and preform handling and mold loading/unloading, he says, adding that ICT has a total of six twin-screw extruders on site, as well as six injection molding machines, in support of its polymer processing research.

A nearby machine is used to make parts that incorporate local continuous reinforcement — that is, continuous carbon or glass fiber rovings or tape wound around load introduction points that are subsequently encapsulated by long fiber-reinforced thermoplastic resin, a concept that Fraunhofer calls Tailored LFT. Roch shows a demonstrator automotive part with visible fiber filaments wound around metallic inserts as anchor points. “Right now, the tapes or fibers are being wound by hand, but we will soon have a robot for winding.” He points out that the minimal use of continuous fibers, only in the areas of highest load, with the rest of the part made with commodity thermoplastic, provides homogeneous stress distribution in the part and significantly higher breaking strength compared to a plastic part without the continuous fiber reinforcement.

Roch next shows a work area containing a prototype consolidation station currently in use by a Ph.D candidate who is developing a new methodology for rapidly heat-welding thermoplastic tape blanks together. Termed radiation-induced vacuum consolidation (RVC), the method’s details are currently proprietary, yet Roch points out that the method could meet a big need. “Thermoplastic tape laying is a great technology, especially with the RELAY machine approach, but the consolidation and debulking of the material has always been a roadblock. We’re hopeful that these experiments will be an enabler for cost-efficient tape processing.”

Passing through the hall, he points out a new injection molding machine for making small parts, including sample plaques for polymer testing and small plastic clips used for tagging live birds. A large ENGEL AUSTRIA GmbH (Schwertberg, Austria) duo 700 pico combi M injection molding machine is next, usable for standard injection molding, for direct long-fiber thermoplastic (D-LFT) molding or foam injection molding of LFT granules using the MuCell microcellular foam process from Trexel Inc. (Wilmington, MA, US). The 700-ton machine has two injection units, back to back, which enables co-molding, says Roch, and the inner mold part of a stackmold, mounted on a rotary table, can be turned 180° to allow injection from both sides.

He points out that the glass fiber rovings are fed into the machine from above, and the glass fiber package creel: “With this direct LFT technology,” he notes, “you become your own custom compounder, using longer fiber lengths than are available from compounders, and you can save to 20 to 30% of the cost of pre-made pellets.” One of the machine’s injection units is used to make the long fiber-reinforced, in-mold foamed sandwich parts explained by Roch at the beginning of the tour; he points out where the foaming agent enters the barrel, either a chemical foaming agent or nitrogen gas (the MuCell process). In addition, robotic handling of heated organosheet and preforms can be integrated with this machine for overmolding (see Breathing-mold process yields sandwich composite from LFT).

Adjacent to the Engel machine is a display of semi-structural reinforced foam automotive parts that Roch’s group has produced for prototyping, including an underbody shield and instrument panel (IP) carrier for several automotive Tier 1s. Also on display are structural D-LFT parts (PA6 with 30% glass loading). Roch says that, in his opinion, the future of automotive composites will be shaping of organosheets (continuous fiber thermoplastics) that are subsequently overmolded via injection: “We’re at an early stage now, but we believe there’s a lot of potential.”

SMC, preforming and RTM

Roch leads the way out of Building 90 and walks past several office buildings towards the polymer engineering group’s new laboratory and shop building. Built to house the group’s massive Dieffenbacher 3600-ton compression press, it’s the center of ICT’s long fiber-reinforced thermoset activities — primarily work related to sheet molding compounds (SMC). Although a signboard blocks the doorway, with a chalked message prohibiting entry due to OEM partner molding trials, Roch enters, and gets the all-clear for the visit. Although those not involved in the market might be hard-pressed to know what part for which car model they were seeing, Roch explains that sharp-eyed automotive industry visitors could tell at a glance from a mold shape what types of trials were being run, hence the precautions.

Roch proceeds past the press to the back of the building, where he points out an SMC line that feeds into the press. An adjacent, second SMC line, set up for direct long-fiber-reinforced SMC (Direct SMC), was there during the visit, but has since been removed and replaced with a new RELAY tape-laying machine. The RELAY will be combined with a new injection unit installed in August 2017 for thermoplastic co-molding of organic sheets, either fabric or unidirectional tapes, produced by the RELAY machine.

Further downhill, Roch opens the door into another lab, where high-pressure resin transfer molding (HP-RTM) activities are housed. Near the door is a preforming center within a safety cage, equipped with a robot to transfer material from an automated cutting table to a heated shaping mold. The preforming setup is similar to the Dieffenbacher PreformCenter installed in Fraunhofer’s Ontario, Canada, facility in 2014. Roch explains that the preform shaping mold is capable of complex sequential movements during closing, that allow for a highly shaped part preform without wrinkles. A structural part for Mercedes Benz is displayed outside the cage, which shows how the relatively high-areal-weight woven carbon fiber twill fabric conforms without pulling or wrinkling (see photos).

Inside is a large KraussMaffei HP-RTM epoxy injection unit, with an impingement mixing head for fast-cure epoxy resins, paired with a 630-ton Dieffenbacher press. Fraunhofer is investigating two types of HP-RTM: the first is high-pressure injection resin transfer molding, in which the resin is injected under high pressure into a completely closed mold, and the resin flows through the plane of the preform, in the x- and y-directions.

The second is high-pressure compression resin transfer molding, in which the mold is left slightly open, and the resin is injected into the mold gap at low cavity pressure; the mold is then closed completely, and high pressure is applied to the preform, which helps fill the preform in x-, y- and z-directions, with a lower total cycle time.

A large Wickert Maschinenbau GmbH (Landau in der Pfalz, Germany) heating unit provides contact heating for unidirectional thermoplastic tape blanks prior to forming in another press. Says Roch, “We have given our older RELAY unit, previously in this building, to the IGCV group in Augsburg.”

Meeting challenges of composites applications

Last on the tour is Building 14, which houses several more work centers and machines, related to older polymer composites research that might not be cutting edge but still deserving investigation for production auto parts. For example, a KraussMaffei polyurethane RTM injection unit sits near a production cell for long-fiber injection molding with polyurethane resin. Within the cell, a FANUC (Oshino, Japan) robot works to transfer cut materials to a heated mold, into which PU is sprayed. Also still in use is what Roch calls an “old” process of thermoplastic RTM, which includes an injection unit for a reactive nylon system that creates PA6 in the mold while wetting out the reinforcements, to create reinforced TP parts. The process has been looked at by several automotive OEMs, including Volkswagen, for several years.

As the tour concludes, back in the atrium of Building 90, Roch says, “We’re trying to develop automated processes to reduce the labor of producing composites, to create a robust infrastructure for production of automotive components.” Indeed, the reach of Fraunhofer ICT’s research and process development spans several continents, and the drive to improve composites processing shows no sign of slowing.

Related Content

Seat frame demonstrates next-generation autocomposites design

Light weight, simplified/cost-effective manufacturing, passenger comfort and safety informed materials and process innovations and won awards for the 2022 Toyota Tundra‘s second-row seat frame.

Read MoreBlueHalo launches next generation of Intense Eye UAS

Unmanned aerial system (UAS) from BlueHalo featuring an HX5 injection-molded chassis from Alpine Advanced Materials is said to be lighter, stronger and more efficient than aerospace-grade aluminum.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More