Celeste is an under-construction, 12-meter power catamaran designed by Roger Hill and built by boatbuilder Grant Symmans at G&T Marine (Auckland, New Zealand). The privately owned, custom-built, displacement hull power cat is said to be on track for a May 2023 delivery, thanks in part to the ease of assembly with ATL Composites’ (Molendinar, Australia) composite DuFLEX panels and Z-press system. The vessel is a single-level sedan with a beam of 4.8 meters — a “fairly straightforward” build, Symmans notes.

Symmans was accustomed to traditional materials like plywood, timber and fiberglass skins, but says he was intrigued by the reported benefits of DuFLEX like its precise cut, time and labor savings and minimal waste. In addition, boat designer Roger Hill had used the technology before and recommended it for the project. Symmans notes that the preliminary design for Celeste was based on standard, foam-cored composite boatbuilding methods like infusion, and that DuFLEX ended up being the most cost-effective option. “It’s a first for me. It’s labor-saving, comes as a kit and the DuFLEX is light and sturdy,” he says.

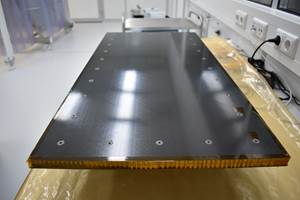

DuFLEX panels are lightweight, prefabricated custom panels that are constructed from E-glass reinforcement, epoxy and a balsa or foam core. For Celeste, DuFLEX panels are used for the superstructure, cabin top and hulls. The hull bottom comprises 20-millimeter H100 DuFLEX strips made from 460-gsm unidirectional (UD) E-glass cored with Divinycell foam from Diab (Laholm, Sweden). The hull sides are laminated with 800-gsm quadraxial E-glass and Divinycell core to meet performance and engineering requirements.

Specifically designed to reduce construction time, DuFLEX panels are delivered ready to assemble, either manually with an adhesive or with the aid of ATL Composites’ Z-press. Using ATL’s Z-Press streamlines the composite panel joining process, applying heat and pressure to cure the epoxy adhesive on Z-joints pre-machined into the panels. Joints cure fully in seven to 20 minutes, depending on the ambient temperature, type of hardener, core type and thickness of the panel.

“Using DuFLEX has made construction a simple process, and at this stage we’re impressed with it,” Symmans says.

Roger Hill, specialist power multihull designer, says the client was a previous yacht owner who sought a well-appointed power catamaran for “the next phase of his cruising lifestyle.” He notes that displacement hull catamarans “cruise most economically around 14 to 15 knots, or about twice the speed [yacht owners] have been used to going all of [their] previous boating life, and they are really fuel efficient.”

The catamaran is a standard design with a few unique features such as a swimming dive platform that lowers down to form steps and a launching platform for a rigid inflatable boat (RIB).

The decision to use the DuFLEX system was made when the client saw it for himself, visiting the 16-meter Omahu and speaking to its owner who had a previous sailing cat built out of DuFLEX and was positive about the process. “The client, whose father was a New Zealand timber boatbuilder and built many cold-molded Kauri sailing yachts, was quite tentative about the process but is now also becoming much more relaxed and happy as he sees the boat coming to life.”

Related Content

Running shoe insoles get a lift with thermoplastic fiberglass tapes

FlexSpring insoles take advantage of unidirectional, continuous fiberglass and thermoplastics to enable next-level performance for the everyday runner.

Read MoreCarbon fiber satellite arm reduces weight, simplifies assembly onto naval vessels

Satcom developer EM Solutions partnered with ACS Australia to replace an aluminum arm design with a 65% lighter, one-piece, corrosion-resistant carbon fiber/epoxy alternative.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreNanomaterials optimize performance of space-ready carbon fiber composite panels

A recent ESA project led by Adamant Composites aimed to mature nanomaterial-enhanced CFRP for lighter weight, more thermally and electrically conductive materials for manufacturing satellite structures.

Read MoreRead Next

Composite panels aid design of prefabricated apartment addition

Glass fiber/epoxy sandwich panels achieved structural requirements, complex geometries and challenging installation needs for London apartment renovation.

Read MoreMonash Motorsport constructs FSAE autonomous, electric vehicle with ATL Composites materials

Composite are incorporated into the vehicle’s monocoque chassis, aerofoils, aerofoil endplates and other components to suit high aerodynamic loads, minimize mass and enhance efficiency for the globally competitive team.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;width=70;height=70;mode=crop)