EasyStreet Systems installed four of its pull-wound fiberglass/polyester poles in July 2023 along an intersection in Peachtree Corners, Ga., U.S. in collaboration with the Curiosity Lab at Peachtree Corners. The aim is to test out the poles in a real-world scenario and also use installed equipment to study traffic patterns in the intersection. Photo Credit, all images: EasyStreet Systems

As 5G networks grow, telecommunication companies are requiring the installation of more antennas and drop zones that are also placed closer together. EasyStreet Systems (Spokane, Wash., U.S. and Tadley, U.K.) is one company developing modular poles for use with small cell 5G antennas.

Founded in 2020, the company aimed to design ultra-lightweight, ultra-strong small cell structures, which led to use of composites materials versus traditional wood or metal options.

“We have found that composite poles are an excellent replacement for aging wood poles in infrastructure,” says Pete Chase, CEO of EasyStreet Systems. One of the top benefits of composites in this type of application is light weight, which enables easier transport of multiple poles to the site at once, and installation with a minimum number of technicians and equipment. Beyond weight, Chase adds, “They resist rot, water absorption, insects and woodpeckers. In addition, composite poles do not lose strength as they age, so maintenance is minimal. All cabling can be run inside the structure, as opposed to wood.”

“The location is key to deciding what material to use for poles,” adds Juha Pesonen, segment owner, telecommunications at Exel Composites (Vantaa, Finland). He explains that composites are ideal for a variety of areas and applications: coastal areas affected by strong winds and corrosive salt, airports and military bases where radar rays need to be able to travel easily, highly populated urban areas where installation can be challenging and more.

EasyStreet designed its first utility poles in filament-wound carbon fiber. Carbon fiber was selected to provide the durability and wind deflection capability required, and at the lowest weight possible for easiest transport and installation.

In October 2021, EasyStreet began working with pultrusion and pull-winding specialist Exel Composites, which proposed switching from filament-wound carbon fiber composite poles to fiberglass composite poles made via pull-winding.

The switch from filament winding to pull-winding came down to speed. “Filament winding was too slow for our production needs, and we wanted a single source that could produce all of our product in terms of quality control,” says Kent Harrison, CTO of EasyStreet Systems.

Moving to fiberglass had multiple benefits. “Fiberglass is non-conductive and less expensive [than carbon fiber]. We added just 25% more weight, with no appreciable difference in strength,” Harrison says.

Pull-winding is similar to more traditional pultrusion, a continuous process in which fiber tows are pulled via guides through a resin bath followed by a heated die, where it is shaped into a composite profile featuring continuous, unidirectional fibers. In pull-winding, fiberglass rovings can either be unidirectionally aligned or helically wound around a mandrel before being pulled through the resin bath and heated die. This combination enables a mix of fibers at various orientations along the profile, and can be tailored according to the profile’s mechanical requirements. In this case, after manufacture, EasyStreet then applies an exterior coating for enhanced UV, fire and corrosion resistance.

Exel and EasyStreet were able to use the pull-winding process to create a pole with optimized fiber orientations to meet stringent wind deflection targets. “We introduced our pull-wound fiberglass option and were able to hit the same wind deflection targets as the carbon fiber,” emphasizes John Mertic, area sales manager at Exel Composites. Pull-winding also “gives more rigidity to the product, so that it doesn’t bend as easily,” Pesonen adds. The redesigned poles were put through a battery of tests by EDM International Inc. (Fort Collins, Colo., U.S.).

The result of the past two years’ design efforts is a pole that weighs about 10% of the weight of a steel pole — EasyStreet claims its 30-foot, 9.8-inch-diameter pole weighs 210 pounds, versus a 2,000-pound steel equivalent. This weight reduction results in easy transport and simple, 2-hour installation using only two people and basic equipment, and amounts to installation cost savings of up to 70% versus steel.

EasyStreet has expanded its product line to include 20-, 30- and 40-foot options that can be outfitted for equipment that enables 5G and 4G connectivity, smart lighting, Internet of Things (IoT) applications, electric vehicle (EV) charging and potentially electric utility poles in future. Currently, the company is working on certification of the poles with the U.K. Department for Transport.

For the Peachtree Corners poles, holes were pre-dug using a hydrovac method, and the EasyStreet poles were easily hoisted and secured using a direct bury method and rapid-set foam foundation. One location was said to be a particularly tight fit, a challenge that the ultra-light poles were well suited for.

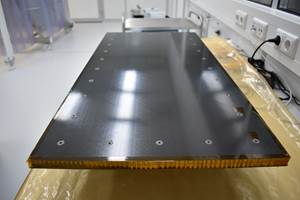

In the meantime, the company is building and testing out poles in a real-world environment. Working with the Curiosity Lab at Peachtree Corners (Peachtree Corners, Ga., U.S.), in July 2023 EasyStreet installed four poles (pictured) around an intersection. The poles, pull-wound from fiberglass-reinforced polyester, carry computer vision, machine learning, object detection and LiDAR equipment for evaluating activity at a busy intersection and providing information on how to ease congestion and help prevent collisions. The four poles were installed in 3 hours with minimal crew and equipment.

The company is working to roll out the product commercially in the U.K. with Exel as its manufacturing partner and in the U.S. partnered with Avient Corp. (Avon Lake, Ohio, U.S.). “The next steps are to branch out into different-sized poles and more uses,” Harrison adds, noting that the company has already received requests for new poles with specialized needs like smaller diameters for a smaller footprint, or higher strength.

Related Content

Bio-based epoxy, recycled materials increase sustainability of all-terrain snowboards

Aiming for a smaller environmental footprint while maintaining high performance, Salomon’s Highpath snowboard line incorporates bio-based epoxy, glass and basalt fiber stringers and recycled materials.

Read MoreRunning shoe insoles get a lift with thermoplastic fiberglass tapes

FlexSpring insoles take advantage of unidirectional, continuous fiberglass and thermoplastics to enable next-level performance for the everyday runner.

Read MoreNanomaterials optimize performance of space-ready carbon fiber composite panels

A recent ESA project led by Adamant Composites aimed to mature nanomaterial-enhanced CFRP for lighter weight, more thermally and electrically conductive materials for manufacturing satellite structures.

Read MoreCarbon fiber satellite arm reduces weight, simplifies assembly onto naval vessels

Satcom developer EM Solutions partnered with ACS Australia to replace an aluminum arm design with a 65% lighter, one-piece, corrosion-resistant carbon fiber/epoxy alternative.

Read MoreRead Next

Filament wound utility poles offer design flexibility

In Turkey, a utility pole manufacturer combines filament winding, automation, glass and carbon fiber composites to expand its product line.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)