Quiet revolution: Composites in EVs

Startup automakers make use of composite body/chassis components to extend the range of hybrid-electric and battery-electric vehicles.

In the midst of global economic turmoil, long-established automotive OEMs are folding brands, closing plants and struggling to survive, while at the same time trying to engineer more fuel-efficient vehicles that customers will want to buy, yet also will satisfy government mandates. One result is an ongoing race to build production-worthy hybrid-electric and plug-in-(battery)-electric vehicles (HEVs and PHEVs/BEVs respectively).

The prevailing attitude among established automakers is that it’s too risky to change both powertrain and body at the same time. Hence, HEVs produced by OEMs such as Toyota Motor Co. (Toyota City, Japan), Honda Motors (Tokyo, Japan) and Ford Motor Co. (Dearborn, Mich.) each sport a relatively heavy body and chassis — legacy steel and aluminum — that require heavy, large battery packs to achieve combined city/highway U.S. Environmental Protection Agency (EPA) fuel-economy ratings in the mid-to-high 40s (miles/gallon). Indeed, General Motors Co.’s (GM, Detroit, Mich.) impending Volt hybrid, developed with a composite body in mind, is now scheduled for a debut with aluminum body panels.

In the midst of all this, a quiet revolution is taking place. In fact, an insurgency has been spreading for nearly a decade: A determined group of startup automakers — more than two dozen in all — are defying conventional auto-industry wisdom by developing, testing and, in some cases, commercially producing a breed of personal transportation that is new from the ground up. CT profiles five of the most formidable, a group of upstart automakers that have dared to go where established OEMs fear to tread.

The Tesla uprising

The first startup automaker to commercialize highway-legal, composite-bodied, alternative-powertrain vehicles for serial production in the last decade was Tesla Motors (San Carlos, Calif.). When the company launched its sleek, two-passenger Roadster sports car in 2006 (commercial production began in 2008) it overturned the stereotype of ugly, plodding EVs and created a whole new demographic for “green” transportation among car aficionados (see "Engineerign Insights: Not your father's EV," under "Editor's Picks," at right). This was followed by the higher performance Roadster Sport model, which began commercial production last summer. At $109,000 USD (base price), the Roadster does 0 to 60 mph/0-97 kmh in 3.9 seconds and tops out at 125 mph/201 kmh; the speedier and pricier ($128,500) Sport model does 0 to 60 0.2 second faster. In mid-January, at the 2010 North American International Auto Show (NAIAS, Detroit, Mich.), the automaker announced that it had finished its 1,000th production vehicle — an important milestone, given that a year earlier, the company had delivered only 150 cars.

The Roadster was the first production BEV to use lithium-ion (Li-ion) batteries and the first EV with a range greater than 200 miles/302 km per charge, a record previously held by GM’s EV1 PHEV, which was powered by conventional lead-acid batteries. The base Roadster achieves an EPA-certified laboratory rating of 244 miles/393 km per charge (45 percent highway/55 percent city driving) — values that, Tesla asserts, make its BEV twice as energy efficient as Toyota’s Prius HEV and certainly a lot more fun to drive. On Oct. 27, 2009, Roadster customer Simon Hackett drove the entire 313-mile/504-kilometer segment of Australia’s annual Global Green Challenge on a single charge, setting a new world record for BEV range.

The Roadster and Roadster Sport make full use of advanced composites to extend driving range and achieve the high power/weight ratio that make these vehicles so fast and responsive. The Roadster originally featured a mix of autoclave-cured and resin transfer molded (RTM’d) epoxy/carbon fiber-reinforced plastics (CFRP) on all exterior body panels, the center console, and B-pillar cross-beam frames, plus a carbon-armature rear bumper beam. To reduce costs for the second-generation Roadster, some CFRP parts were converted to lower-cost composites (e.g., the RTM’d CFRP boot box, or trunk, was converted to compression-molded sheet molding compound, or SMC). On the other hand, more recent changes include a new exposed-weave CFRP exterior panel set and interior trim kit, produced with autoclave-cured carbon/epoxy prepreg. These options were initially offered on the Sport but are now available for both models. The company also introduced a clearcoated CFRP hardtop that is produced in the same RTM tool used to mold painted hardtops.

Barrie Dickinson, director – body engineering and now program director for Roadster programs at Tesla, and the engineer responsible for developing the vehicle’s CFRP sandwich-panel body, says, “Our experience is that carbon-RTM has offered challenges, but is certainly worth the effort, given its weight-to-stiffness benefits.”

However, despite rave reviews, celebrity endorsements and many technology and vehicle awards for the Roadster models, when Tesla introduced its Model S sedan last year, the decision already had been made to use aluminum for its body. The change, explains Dickinson, is primarily a function of volume and cost, since Model S is lower priced ($57,400 USD) and will be produced in much higher volume than the Roadster (10,000 to 20,000 units/yr vs. 1,000 to 2,000 units/yr). “With aluminum, panel production can be achieved at much higher rates per tool set, and joining the panels — via spot welding or rivets — is much faster than bonding composite panels. It’s also a lot easier to achieve Class A surfaces in stamped metal, which provides the opportunity to increase automation or at least reduce labor content to achieve our high finish standards,” says Dickinson. Lastly, because Model S will have an integrated body structure, stamped aluminum panels, he says, will better contribute to the vehicle’s structural integrity, giving Tesla a more efficient structural solution. “To achieve this design in carbon composites would have been much more costly at Model S production volumes,” he says. While it’s disappointing to see Model S change to aluminum, Tesla has more vehicles in the offing. Early in 2009, the company announced that it is working with Daimler AG (Stuttgart, Germany) to produce a BEV version of Daimler’s thermoplastic-composite-bodied SmartforTwo microcar, whose standard gasoline-engine model is the most fuel-efficient, conventional-powertrain vehicle on the road. And last summer, Tesla announced it had electric minivans, crossovers and fleet vans on the drawing board thanks to loans it had secured from the U.S. Department of Energy (DoE). Regardless of whether some or many of these vehicles end up in composite bodies, Tesla clearly has set the standards for the next generation of HEVs and BEVs.

Return of the phoenix

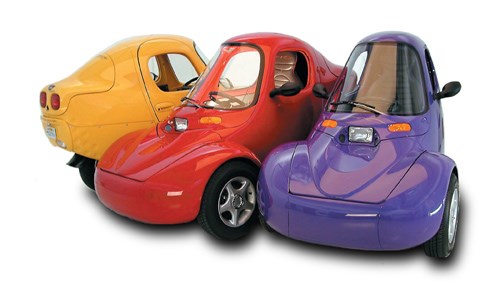

Like the mythical phoenix, a microcar originally developed by Corbin Motors (Hollister, Calif.) and eventually acquired by Myers Motors LLC (Tallmadge, Ohio) was reborn from the ashes of its own demise. In 1996, Corbin Motors (a division of Corbin-Pacific, which supplied aftermarket motorcycle seats, saddles and body styling, and built electric motorcycles) began work on a uniquely shaped, three-wheeled (two wheels in front, one in the rear) commuter BEV called the Sparrow. The first commercial vehicles were offered in September 1999. Two models were produced: a standard version (nicknamed Jelly Bean for its unique styling and bright colors) and a hatchback (called Pizza Butt after Dominos Pizza ordered some for delivery vehicles). Although they seat only one, these BEVs are faster than neighborhood electric vehicles (NEVs) or golf carts, are highway-legal, and allow drivers to travel in high-occupancy-vehicle (HOV) lanes. Several hatchbacks were featured in Mike Myers’ movie, Austin Powers & Goldmember (2002).

The Sparrow’s composite monocoque body featured hand-layed, multilayer fiberglass/unsaturated polyester composites over a three-wheeler chassis. This unibody design was light, strong and surprisingly crash-tough (see the photos and caption in the accompanying short article entitiled "Are EVs here to stay this time?" by clicking on "Sidebar" at the end of this article), and the wide-stance chassis was very stable. Both models are powered by 13 12-volt lead-acid batteries. Battery placement near the front axle and under the passenger seats lower the vehicle’s center of gravity. Sparrows retailed at $13,900 (USD) for the standard model and $16,995 for the hatchback, and had a driving range of 25 to 30 miles (40 to 48 km) per charge, with a top speed of 70 mph/113 kmh. Unfortunately, the batteries typically require replacement after 12 to 18 months. Due to its three-wheeled configuration, the Sparrow was classed as a motorcycle in most U.S. states, for the purposes of determining insurance, licensing and vehicle-safety requirements.

Reportedly, fewer than 300 Sparrows were produced (many were returned for repairs), and two other models were in the works when, in 2003, squabbles with former president Ronald Huch (who was also a board member, stockholder and major creditor) led to seizure of Corbin’s assets. Corbin responded by filing for bankruptcy protection, the courts found for the plaintiff, and Corbin’s assets were transferred to Huch’s company, Phoenix Environmental Motors, which attempted unsuccessfully to revive the Sparrow.

In August 2004, Ohio businessman Dana Myers bought certain assets from Phoenix, hired some ex-Corbin workers and formed Myers Motors LLC, setting up shop in the Akron, Ohio, suburb of Tallmadge. He faced a steep learning curve to understand composites, batteries, manufacturing, passenger vehicles and all that each entails. His team immediately ran into challenges, because the Sparrow was notorious for electrical and mechanical problems. The original body design and construction methods were retained, but the team re-engineered the electrical system and fixed other problems.

The redesigned vehicle — now called the NmG, short for “no more gas” — became available April 2006 at a retail price of $24,900, although an innovative four-tier pricing system dropped the cost as low as $18,900. By 2008, the price had climbed to $29,995 — still far below other highway-legal EVs of the time — and by 2009, the vehicle was equipped with Li-ion batteries (at no additional cost). These were rated for 100,000 miles/160,934 km and reduced the vehicle’s curb weight from 1,600 lb to 1,350 lb (726 kg to 612 kg). Driving range was doubled to 60 miles/97 km and the EPA-equivalent fuel economy rose to 200 mpg (1.18 liters/100 km) from the previous 162 mpg (1.45 liters/100 km). During this period, Myers Motors claimed that there were more NmGs and predecessor Sparrows on the road than all other then-available, highway-legal EVs combined — which is probably true, given that a year ago, Tesla had delivered only 150 vehicles.

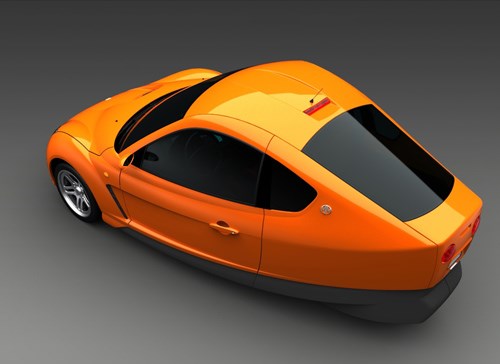

Owing to high production costs, not many NmGs were built and sold, but the company used the experience to learn about the EV market. “It was always our intention to come up with our own vehicle that would become our flagship product,” says Myers. The company did just that in October 2009 when it announced the Duo, a sleek new three-wheeled, two-seat model that will go on sale late this year. Duo, an acronym for “doesn’t use oil,” is also Latin for “two,” a nod to its double occupancy. Like Corbin’s Sparrow, the NmG and Duo are classed as motorcycles. The company again developed a price-reduction strategy: The starting price is $29,995, but for every 200 pre-orders received, the price drops by $1,000 to a maximum discount of $5,000. Federal tax incentives reduce the price further. An optional, 100-mile/161-km extended-range battery pack also will be offered.

The Duo will sport a composite body, but Myers says the company likely will switch from a monocoque to a body-on-frame design and is evaluating numerous materials/process options to reduce production time and costs vs. the previous labor-intensive hand-layup method. “Our goal is to have strikingly different-looking vehicles that express our customers’ individuality and don’t look like everything else on the road,” adds Myers. “But we’re also trying to hold down costs so we can price them affordably for the widest population. We’re asking the composites industry to help us make these new vehicles more cost-effectively.” He made that plea as a keynote speaker at last fall’s SPE Automotive Composites Conference & Exhibition (ACCE) show in Detroit (see “SPE ACCE 2009 Show Highlights under "Editor's Picks”). Myers also is seeking equity investors and government funding.

Fly like a bird

Another startup automaker with a composite-bodied, two-seat, three-wheeled EV is Vista, Calif.-based Aptera Motors (formerly called Accelerated Composites). But this concept demonstrator evokes images of a small, wingless/tailless jet plane with scarab doors. Aptera is Greek for “wingless,” an apt name for a vehicle once described as a cross between a dolphin and a helicopter. The car’s startling design is extremely “slippery” (target drag coefficient, or Cd, is less than 0.20), thanks to swept styling lines, low-rolling-resistance tires and a lightweight monocoque construction. In fact, the vehicle’s unusual shape was derived through extensive optimization using computational fluid dynamics (CFD). The sleek unibody design — which will be offered in both BEV and series-hybrid versions — reportedly will be among the world’s most energy-efficient vehicles, with a fuel-efficiency equivalence of more than 200 mpg (1.18 liters/100 km) for the BEV version if recharged every 100 miles/161 km. These figures, Aptera says, have been verified by simulation and physical testing.

Although the company has accepted vehicle deposits from residents of California, it has been plagued with delays, layoffs, management changes and funding challenges as it produced limited numbers of several design generations. But from the beginning, the company has been focused on a cost strategy that allows it to produce the highest energy efficiency at the lowest barrier to entry. Rather than use advanced composites, such as CFRP, Aptera reinforces most parts with E-glass. Although few details have been released about the newest design, because Aptera and its suppliers are busy filing patents, Aptera’s chief marketing officer Marques McCammon describes it as a “stressed-skin” composite monocoque. It features sandwich panels made with E-glass/epoxy skins bonded to either side of a lower-modulus core and formed in a closed-mold process, then bonded together with high-strength epoxy adhesive. Sandwich construction not only makes the vehicle extremely stiff and strong for its weight but it also provides thermal and acoustic insulation. Composites were critical to the vehicle’s unique shape, which would have been cost-prohibitive to achieve in metals. Energetx Composites LLC (Holland, Mich.) will produce bodies for production vehicles.

Aptera’s biggest development challenges thus far, McCammon reports, are process control and subset tack time. “When planning for production volumes, we can’t have one body come out perfect and another come out needing two hours of rework,” he explains. “Hence, we’ve spent lots of R&D effort trying to define and control factors that contribute to process time and to make them more efficient — from resin system, layup pattern and tooling to the size and shape of the molds.” A key enabler was finding a faster-curing epoxy resin.

Like Myers’ NmG and Duo, Aptera’s three-wheeler is classified as a motorcycle in most U.S. states, so technically it is not subject to the same safety and emissions requirements as passenger cars. Nonetheless, Aptera is quick to point out that passenger safety has been a high design priority. In fact, this is part of the benefit of using composites, says McCammon. Because there is no frame separate from the body-in-white, the composite “shell” performs a structural function. Accordingly, it has been exhaustively evaluated via finite-element structural analyses as well as crush testing of structural components. The result, thus far, is very positive: “These materials allow us to approach the safety question in unique ways and get unique results. Our roof crush strength right now is 3.5 to 4 times higher than what is federally mandated,” he points out. ”Because composites tend toward elastic deformation instead of permanent deformation in a crash, we’re seeing exceptional results.” Eventually, the body design will undergo sled and full-vehicle crash tests.

Early indications are that it should perform well — at least on par with conventional cars. Contributing factors include that the unibody forms a rigid cage similar to those on Formula One cars, the carriage is fairly high vs. most passenger vehicles, and the design features relatively large front and rear crumple zones for a vehicle its size. For greater stability with this high carriage, battery modules are placed under the cockpit, giving the vehicle a lower center of mass.

Green features on the vehicle include the use of post-consumer-recycled (PCR) polyester fabrics from soda bottles for seating and carpet (leather and leatherette options also are planned); seat padding from carbon-sequestering soy-based foams; plasticizer- and heavy-metal free interior plastic components; and use of energy-efficient light-emitting diodes (LEDs) for running and interior lights. Prototypes feature a large roof-mounted solar panel, which can power the vehicle’s low-voltage electrical systems, including HVAC, audio/entertainment and other accessories.

Aptera’s Li-ion-battery-powered drivetrain reportedly can accelerate from 0 to 60 mph (0 to 97 kmh) in less than 10 seconds and reach a top speed of 90 mph/145 kmh. Initially, a BEV version will be released (called 2e), followed by a series-hybrid version (called 2h). The latter will feature a small gas-powered generator to extend the driving range. Unlike a conventional HEV, the engine won’t power the drivetrain but rather will only recharge the batteries.

Current target prices are in the mid-$20,000 to mid-$40,000 range, depending on the customer’s selection of powertrain and option packages. Of course, the question everyone is asking is, When will vehicles be available for sale? McCammon says, “We’re holding off on statements on timing as we wait for a new round of financing to close in the next few weeks.” Like most U.S. EV companies, Aptera has applied for the DoE’s Advanced Vehicle Technology Manufacturing loan program, and also is one of 50 teams in contention for the Progressive Automotive X PRIZE (see “Automotive X Prize ...." under "Editor's Picks”).

Good green Karma

Another entrant in the HEV sweepstakes is Fisker Automotive, a joint venture between vehicle designer Fisker Coachbuild LLC and hybrid-drivetrain manufacturer Quantum Technologies. Founded in 2007 in Irvine, Calif. (also home to its parent companies), the joint venture introduced its four-passenger Karma, an extended-range HEV in the “premium performance/luxury” segment, at the 2008 NAIAS in Detroit. More than 50 patents have been filed with respect to its technology and, reportedly, the company already has secured more than 1,600 customer deposits. It expects to have vehicles for sale late this year — an astoundingly fast turnaround for a completely new platform, particularly one fielded by a startup automaker.

Key to the speed with which Fisker has moved is its unusual business model: The company is primarily an engineering and marketing organization. Almost all design, part production and assembly is outsourced to experienced contractors, a decision that reduced time-to-market and overall development cost. The Karma’s elegant, low-slung styling came from Fisker Coachbuild. EDAG (Fulda, Germany) provided engineering support. Magna Intier (div. of Magna International, Aurora, Ontario, Canada) developed and will produce the cockpit/interior. The vehicle’s all-aluminum spaceframe was developed by Fisker with support from Norsk Hydro (Oslo, Norway) and will be assembled by Valmet Automotive (Uusikaupunki, Finland). While components for the vehicle’s proprietary electric drivetrain will be supplied by Quantum,

Fisker is sourcing many other components (e.g., the turbocharged-gasoline engine) as off-the-shelf purchases from other automakers, the majority of which come from GM. Aside from its spaceframe, the company has been evasive about what materials actually comprise the body panels, saying only that it will be a mix of aluminum and composites.

Fisker has been more open about features designed to make the Karma a “serious environmental alternative” in its category. Like Toyota’s latest Prius and Lotus Car’s (Hethel, Norfolk, U.K.) ECO Elise demonstrator (see “ECO Elise concept ...." under "Editor's Picks”), the Karma sports a solar panel — Fisker claims it is the world’s largest automotive solar panel — as a standard feature, designed to help recharge the battery and cool the interior. The company also will offer customers solar panels for their roofs/garages, allowing for off-grid recharging of the vehicle.

In keeping with Fisker’s green-luxury mantra — to produce the world’s first “eco-chic” cars from equally “eco-chic” production facilities — the Karma will feature three interior trim packages: EcoBase, EcoSport and EcoChic. At the top end, EcoChic breaks new ground in “green” design. The sustainably farmed and manufactured, hand-wrapped premium leather trim of the EcoSport package is replaced by an animal-free interior of high-grade textiles, woodwork from fallen, sunken or partially burned (rescued) trees, and EcoGlass trim-frames featuring fossilized leaves that surround the center-console control panel. Company founder and former Aston Martin (Warwick, U.K.) design chief Henrik Fisker notes, “The Karma’s material philosophy balances sensuality and accountability.”

Fisker explains that its Q-DRIVE driveline will emit just 83 grams of CO2/km and, according to SAE International’s methodology for measuring equivalent fuel economy for hybrids, will have an average fuel-economy rating of 67 to 100 mpg (2.4 to 3.5 liters/100 km) — quite frugal for the luxury segment. In pure electric mode, the vehicle’s 403-horsepower twin electric motors on the rear differential provide a range of 50 miles/80 km. Thereafter, the car operates in sport (hybrid) mode. It’s turbocharged 4-cylinder Ecotec gas engine (from GM) kicks in to turn a generator that powers the electric motors, providing supplemental electricity to drive another 250 miles/402 km. In sport mode, the Karma can accelerate from 0 to 60 mph in a respectable 5.8 seconds (0-100 kmh in 6 seconds) thanks to the drivetrain’s impressive 959 ft-lb/1,326 Nm of torque. (In contrast, the speedier all-electric Tesla Roadster in sport mode produces only 295 ft-lb/400 Nm of torque, but is two seconds faster. Both vehicles are limited to top speeds of 125 mph/201 kph.)

At $88,000, the four-door Karma will have a select customer base, as will a second, pricier two-door hardtop-convertible model, the Karma Sunset. However, the company has already announced Project NINA, for development of a lower cost, family sedan in the $40,000 price range by 2013. Eventually, the company plans to produce three models of this midsize sedan.

Decarbonizing the fleet

Anderson, Ind.-based startup Bright Automotive hopes to launch a line of unique PHEV light-duty delivery vans for commercial fleets. A spinoff from notable green-car think tank, the Rocky Mountain Institute (Snowmass, Colo.), Bright was founded in 2008 by John Waters, the inventor of GM’s EV1 battery system and an alumus of battery makers Delphi Corp. (Troy, Mich.) and EnerDel (Indianapolis, Ind.). Bright has a very aggressive business model, born of a desire to develop EVs in less time and at lower cost than traditional automakers. To do this, Waters says he has assembled a 30-person team of “automotive entrepreneurs” with more than 200 years’ combined experience in vehicle engineering, including some of the world’s most-experienced HEV and battery-pack engineers.

Although electric delivery vans aren’t as glamorous as electric sports cars, they could have far greater green impact, in the long run. In North America alone, half-a-million panel vans are sold each year. Replacing gas-powered vans with electrics would significantly cut greenhouse-gas emissions and validate EV technology by saving fleet customers millions of dollars annually. According to Bright, a fleet of 250,000 HEV vans would prevent the release of more than 59.5 billion lb (27 million metric tonnes) of CO2 and save 2.8 billion gal/11 billion liters of fuel during an estimated 150,000-mile/241,402-km lifecycle.

Collaborating with a consortium that includes ALCOA (Pittsburgh, Pa.), Google.org (Mountain View, Calif.), Johnson Controls (Milwaukee, Wis.), and the Turner Foundation Inc. (Atlanta, Ga.), plus engineering-development partners, including Multimatic (Markham, Ontario, Canada), EDAG and Plasan Carbon Composites (Bennington, Vt.), Bright went from clay models to a fully functional prototype in an astounding four months. Called the IDEA, the van was intentionally designed with input from fleet owners and operators and, according to Bright, it’s 5 to 10 times more efficient than conventional vans, which typically get less than 15 mpg (16 liters/100 km). Bright’s plug-in hybrid features a parallel road-coupled drivetrain. In pure-electric mode, battery packs drive the rear wheels. As battery charge depletes or more power is required, a 2.0-liter gas engine kicks in to propel the front wheels. Because the powertrain is designed to sustain a minimum battery charge, HEV performance is seamless and, when the gas engine is engaged, offers all-wheel-drive capability — a boon to fleet owners who normally purchase separate 4WD vehicles for snowy climates.

Aerodynamic styling, aluminum and composite construction, and features such as low-rolling-resistance tires help reduce the IDEA’s Cd from the 0.32-to-0.37 range typical for this vehicle class to less than 0.30, contributing further to mass decompounding. With 180 ft3/5.1m³ of storage space, a 2,000-lb/907-kg payload, asymmetrical rear doors, and a passenger seat that converts to a mobile office, driver safety, comfort and convenience were designed-in from the start. An integrated bulkhead separates passenger and cargo compartments, increasing occupant safety by eliminating the risk of flying debris. Further, the bulkhead transfers crash loads better than a design without bulkhead. Select use of composites in key components, such as the bulkhead, mobile office/seat and structural battery box, helps decompound mass further.

“Weight is important with traditional-powertrain vehicles, but it’s especially critical for EV and PHEV platforms, where battery costs are so significant. Reducing weight to keep battery size down is an overriding factor for us,” says Hadrian Rori, Bright’s VP of vehicle engineering. “Also, as a startup, we have to be frugal from a capital perspective, and composites provide a fairly investment-efficient means to develop a unique product.” Rori, who launched 20 vehicles during his 24 years at Chrysler Corp. (Auburn Hills, Mich.), told an audience at the 2009 SPE ACCE show that Bright has a strong desire to convert components to lightweight composites and a willingness to pay a premium of $5/lb of weight saved to accomplish that end.

The fully functional demonstrator premiered in April 2009 and it’s already exceeded initial performance estimates, thanks to a new 13 kW-hour battery pack, which increases range in electric mode from 30 to 40 miles (48 to 64 km). Once batteries are depleted, the vehicle gets approximately 50 mpg (4.7 liters per 100 km) of gasoline in hybrid mode.

A composite box/bed for a future cab/chassis model is under consideration, and Bright is developing other revenue streams, offering “high-caliber automotive solutions” to other companies. These include design/engineering services and energy storage and propulsion systems, HEV/BEV conversions and consultation on EV development. In fact, Bright already has contracts with the U.S. Postal Service and U.S. Department of Defense (DoD) to develop EVs and PHEVs, as well as with Volkswagen AG (VW, Wolfsburg, Germany) to do conversions of current production vans, such as the VW Transporter. While not as efficient as a scratch-built van, the forthcoming conversions provide a practical bridge between concepts shown on the IDEA demonstrator and production PHEVs while increasing fuel-economy roughly 3.5 times. Reportedly, Bright also is close to an agreement with an unnamed automaker on a partnership. And Chinese investors are trying to woo the company to move to their shores. Meanwhile, Bright awaits word on a $280 million loan request to the DoE, which would provide funds to build the first IDEA manufacturing facility.

Related Content

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

Engineering Insights: Not Your Father's EV

A stylish composite body makes the world's first all-electric sports car not only lean and green but efficient and fast as well.

Read MoreAre EVs here to stay this time?

Right now, established and startup automakers are expending a lot of time, effort and capital to put electric vehicles (EVs) on the road.

Read MoreSPE ACCE 2009 Show Highlights

The Society’s annual conclave highlights composites use in new hybrids and electrics and its prospects in a “post-depression” auto industry.

Read More

.jpg;width=70;height=70;mode=crop)