Rapid layup: New 3-D preform technology

Hook-and-loop fasteners speed layup of carbon, aramid, glass and hybrid fabrics while improving composites’ mechanical performance.

Share

Today, it is beyond dispute that three-dimensional (3-D) fabric preforms can produce high-performance composite parts in sizes ranging from small to gigantic. But for high-volume industries, such as the automotive sector, 3-D preforming processes have been, thus far, too time consuming and, therefore, too expensive to be a serious materials/process option for production cars. But that could change with a new technology that offers the opportunity to automate time-consuming and labor-intensive hand layup of 3-D preforms. The technology, a 2010 JEC Innovation Award winner in the Materials category, is tradenamed Han-3D fabrics and Han-3D composites (global pat. pend.). It is the brainchild of inventor Dr. Nathan Nanlin Han, a cofounder (with a group of other experienced Ph.D.-credentialed professionals) and the president of two firms that specialize in the development and production of unique 3-D composites and nanocomposites: 3D Nanocomposites Inc. (Valencia, Calif.) handles product development for fabrics that are produced by its sister company Advanced Fiber Materials Technologies Co. Ltd. (Jiangsu, China).

The 3-D preform was developed to overcome an inherent weakness of 2-D layup. Han explains that although the tensile strength of carbon or glass fibers can exceed 3,000 MPa — far stronger than steel — the resin matrix that ties fiber plies together has a tensile strength of about 100 MPa, or 1/30th that of the fibers. If only the resin binds fabric layers together in the ply stack, then this low interlaminar strength can lead to delamination and out-of-plane failure under a variety of load conditions, especially impact and compression fatigue loads. Although it is true that the tensile strength of the polymer matrix can be increased by boosting crosslink density and other means, this is a challenging avenue that increases resin system cost. Other efforts to increase ply-stack strength in the z-direction have focused on mechanical approaches, such as through-thickness stitching, 3-D weaving techniques, and insertion of Z-pins. Although they promise improved impact strength, 3-D stitching and weaving require complex machines and processes, and all three approaches reduce the flexibility and efficiency of the composite, and, of course, increase its cost.

Han says the biggest obstacles to widespread adoption of composite structures in the auto industry are the lack of mass-production efficiency and the high cost of many technologies. “Hand layup is okay when making components for airplanes and even boats,” he notes, “but it is just too slow to be practical for automobile production.”

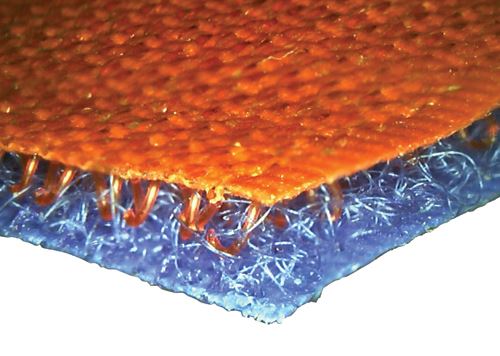

Han’s method for weaving fabrics that overcomes these limitations. Similar to Velcro (Velcro USA, Manchester, N.H.), Han’s fabrics are fitted with hook-and-loop fasteners — hooks on one side and loops on the other side. The technology seems to be applicable to nearly any fiber type or hybrid and enables fast, easy assembly: As fiber plies are stacked, adjacent plies are locked together by the fasteners, which then function like transply reinforcing fibers, improving Z-axis mechanical strength. “With our new hook-and-loop fabrics and a robotic layup arm, we can produce a preform in 90 seconds,” Han claims. “When combined with epoxies that now cure in two minutes, a car body or chassis can be produced in less than five minutes by the RTM [resin-transfer molding] process.”

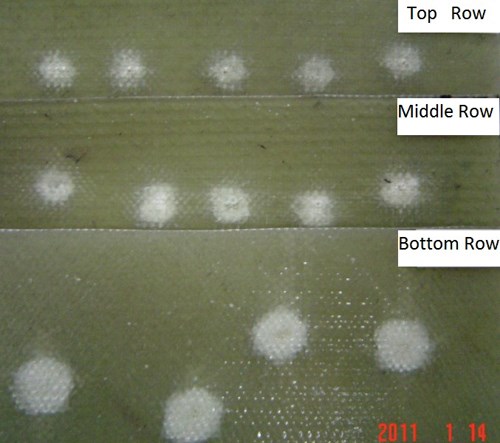

Reportedly, virtual prototyping has predicted and physical testing has shown that composites made with these fabrics benefit from improved mechanical performance: tear strength increases 50 to 100 percent, compressive strength goes up by 20 percent, bending strength by 10 percent, shear by at least 15 percent and impact strength improves by 60 to 100 percent. And part fatigue, bolt-hole strength and bonding strength are all improved.

There are cost benefits as well. Han’s fabrics are produced and sold at a price roughly comparable to other complex reinforcing fabrics. The Han fabrics, with the aid of a robotic arm, can be moved from the cutting table and placed accurately in the mold. The result, says Han, is that direct production costs can be reduced by 50 percent, and indirect costs can go down an additional 30 percent, vs. conventional laminated composites.

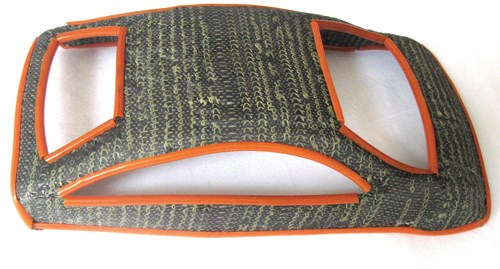

The development phase for Han-3D fabrics is now complete, and preliminary hook-and-loop fabrics are commercially available in China and the U.S. Development work is underway on alternative mushroom-shaped fasteners similar to 3M’s (St. Paul, Minn.) Dual-Lock system, and a means to produce prepregs. The company claims that both technologies could be used in 10 to 25 percent of the composite products currently produced worldwide. To prove the point, Advanced Fiber Materials Technologies Co. produced the fabric from which Jiangsu Xinri E-Vehicle Co. Ltd. (Wuxi, Jiangsu, China) preformed and molded the floor panel on its 2011 model year XR-EV05 electric vehicle, using Owens Corning Composite Materials’ (Toledo, Ohio) glass fiber and Araldite LY564 epoxy resin from Huntsman Advanced Materials (The Woodlands, Texas). Additionally, Shandong Shuangyi Group Co. Ltd. (Dezhou, China) is using the 3-D fabrics to mold wind turbine nacelle covers and other products.

3D Nanocomposites Inc. is seeking venture-capital investors, government funding and partners to accelerate application of the technology.

Related Content

Automotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreThermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;width=70;height=70;mode=crop)