Evonik Corporation

Industrial Chemicals

299 Jefferson Rd.

Parsippany, NJ 07054 US

877-202-3463 | 973-929-8395

composites@evonik.com

evonik.com/composites

About Evonik Corporation

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Evonik Corporation Supplies the Following Products

- Acrylic

- Bismaleimide (BMI)

- Coupling agents

- Curing agents, amines

- Curing agents, others

- Decorative

- Epoxy

- Epoxy, 250 F cure

- Epoxy, 350 F cure

- Epoxy, Paste

- Epoxy, Solvent-based

- Epoxy, toughened

- Foam core, polymethacrylimide (PMI)

- Hardeners

- In-mold

- Methyl methacrylate

- Nanomaterials (carbon nanotubes, fullerenes, etc.)

- Nylon (polyamide)

- Other additives/modifiers

- Other catalysts/promoters

- Other thermosets

- Paint

- Polyether ketone family (PAEK, PEKK, PEEK)

- Powder

- Prepreg

- Protective

- Sizings

- Tape, unidirectional

- Urethane

- Urethane, Paste

- Urethane, Solvent-based

- UV stabilizers

Editorial, News, and Products

-

Evonik publishes life cycle assessment data in online database

Evonik has made LCA information available for its High Performance Polymers Plastics database, which incorporates its fiber-reinforced and transparent polyamide products.

-

Reprocessable, repairable and recyclable epoxy resins for composites

CIDETEC matures 3R resins for aerospace applications via AIRPOXY program.

-

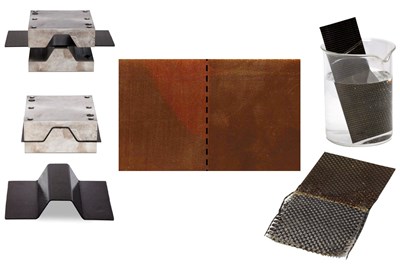

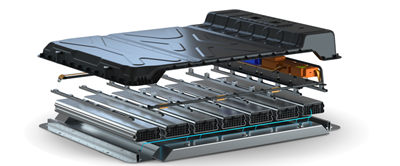

Evonik-led group targets epoxy SMC for EV battery housings

Epoxy modified with an amine-based hardener is applied in a demonstrator EV battery housing. The result is a thermally and mechanically robust structure that offers scalability in a variety of e-mobility applications.

-

Impact tests on RAMSSES ship hull demonstrator show resilience of composites

Damen Shipbuilding and project consortium partners test 6-meter-high, resin-infused composite hull section.

-

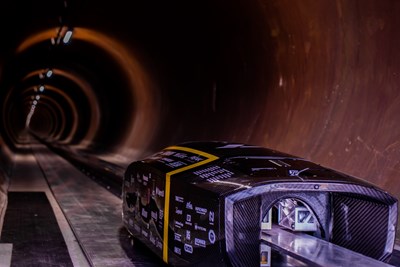

TU Munich gears up for full-scale Hyperloop demonstrator

As a new, university-directed research program, the Technical University of Munich Hyperloop team works to scale up its SpaceX competition-winning pod design.

-

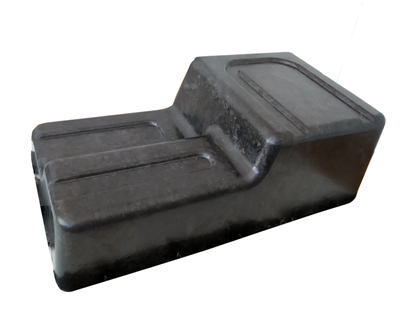

Combination of automation, rigid foam core enable high-volume aircraft part production

A feasibility study demonstrates increased production capacity using Evonik foam core and automated manufacturing.

-

Evonik's VESTALITE S curing agents win automotive award

Evonik’s epoxy hardener for use in SMCs for automotive applications won IALTA’s 2019 Automotive Lightweight Green Technology Award.

-

Evonik expands U.S. production capacity for ROHACELL foams

The expansion includes a new production hall and is scheduled for completion in the fourth quarter of 2020.

-

Continuous fiber-reinforced thermoplastics data added to CAMPUS database

The new data, which will be released in October, is the result of an ongoing material standardization and characterization effort led by German reinforced plastics company AVK.

-

Can the automotive industry turn to face the change?

SPE ACCE speakers speculate about how changing consumer behaviors might shape the automotive industry.

-

AZL production system wins JEC Innovation Award

AZL’s UItra-Fast Consolidator Machine, winner of the JEC Innovation Award 2019 for Industry/Equipment, will be the subject of further research into commercialization of the machine.

-

JEC World 2019: Evonik

Curing agents and cores specialist Evonik introduced two new products at JEC World 2019.

-

Fast manufacturing of tailored composite blanks

AZL and 12 partner companies have completed a research project to develop a new machine prototype allowing increased speed for manufacturing tailored composite blanks.

-

Evonik launches low-odor reactive diluent

In adhesive formulations, composite resins and gel coats, the reactive diluent can replace styrene and methyl methacrylate, either partially or in full.

-

Evonik launches composite polymers for enhancing performance of bone fixation devices

RESOMER composites feature precise degradation rate profiles and mechanical properties such as elastic modulus that can be tailored to match the natural bone.

-

Composites bucking the market trend in M&A

During 2015 and 2016, the composites industry saw such impressive activity in mergers and acquisitions, it was perhaps to be expected that, in 2017, we would see a dip in transaction levels, especially given the global regulatory uncertainty and the impact that might have on larger, more complex deals.

-

CFRP bests steel in precision ball joints

Near-zero backlash in bearings and automation components.

-

Plant Tour: BENTELER SGL, Ort im Innkreis, Austria

High-volume CFRP structures pioneer makes industrialization and multimaterial assembly look easy.

-

Wait, wait, there’s more: JEC 2017

There’s never enough time to see everything at the JEC World event, and this year the problem was even worse. Here’s more information on new products and companies, from Paris…

-

CAMX 2016 Show Report

The 3rd annual joint ACMA/SAMPE-sponsored trade event comes to Anaheim with an exhibition and conference program attractive to professionals across the composites world.

-

Evonik is conducting research on biodegradable composites

The research is focused on new composite materials for the fixation of fractured bones.

-

Fine-tuning fiberglass: Smart fiber sizing

Some insights into those proprietary chemistries that can customize performance at the fiber/resin interface.

-

Reducing manufacturing cost via RTM

Airbus Bremen aims to replace dozens of prepreg components and assembly operations with a unitized multispar composite flap molded in a one-shot process.

-

Record-breaking land speed bicycle built with composites

The use of carbon fiber with Scott Bader’s Crestapol 1250LV infusion resin inside and out of the ARION1 land speed bicycle was extensive to achieve the strength to weight ratio needed for this type of speed challenge vehicle.

-

CFK-Valley Stade Convention 2015 report

The composites industry in Germany is preparing for the 4th Industrial Revolution.

-

Additives and modifiers: Matrix optimization

New and reengineered modifiers for thermosets and thermoplastics target previously elusive goals in composites processing and performance.

-

Fiber sizings: Coupling agent companions

Although the primary function of sizing is to protect the fiber from abrasion damage by acting as a dry lubricant during processing functions such as weaving, sizing expert Andy Brink, business development manager at Michelman SARL (Cincinnati, Ohio), says sizings on reinforcements used in composites also contribute to adhesion at the fiber/resin interface.

-

Wichita welcomes SAMPE Tech

The Society’s Fall Conference flourishes in one of the epicenters of U.S. aerospace activity.

-

COMPOSITES+POLYCON 2009 Showcase

Despite the deepening recession, composites pros returned to the show in its new time slot to explore the wealth of products and services collected here.

-

SAMPE Europe/JEC Composites 2009 preview

SAMPE Europe’s 30th annual spring conclave and the nearby JEC Composites Show characterize the latest in material and process technologies.