Roof Module Reflects Well On Paintless Composites

Unique long-fiber injection process yields a paintless high-gloss finish, 20 percent weight reduction and improved safety -- all in one shot.

Much has been said -- and done -- about the "pops" or craters in the painted surfaces of compression molded composite exterior automotive body panels that, until recently, raised doubts about the utility of sheet molding compound (SMC) in applications requiring Class A finishes. New SMC resins, improved compounds and the use of special sealers and primers have significantly reduced these defects to within industry acceptable reject rates (see CT February 2004, p. 16). But automaker smart Gmbh (Böblingen, Germany, a business unit of DaimlerChrysler) had a better idea. Why not eliminate the painting process altogether?

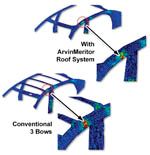

For the smart roadster and several other models, the company challenged ArvinMeritor (Troy, Mich., U.S.A.) to develop a paintless roof module with a durable, glass-like surface, recalls Stefan Ricker, ArvinMeritor's roof modules program manager, "because they intended to build an entire car, which needn't be painted in the plant." ArvinMeritor operates more than 150 manufacturing sites worldwide, including six that, together, produce more than 2 million automotive roof systems each year, using a variety of fabrication techniques. The company's Gifhorn, Germany facility responded to smart's challenge by developing an innovative long-fiber injection molding process that enables comolding of a "paintless" exterior shell made from a thermoformable surface film with a glass-reinforced polyurethane understructure and a finished fabric headliner. The result is the smart roadster's removable "hardtop," which is produced in two halves, weighing only 5 kg/11 lb each, which can be stowed in the car's rear luggage compartment. The roof weighs 20 percent less than a comparable steel roof, thus improving fuel economy and reducing rollover risk by lowering the .roadster's center of gravity. Arvin Meritor's one-piece roof modules for other smart cars have similar weight savings. The fully integrated structural composite sandwich also includes thermoformed water channels and all hardware and electrical system inserts. Additionally, the module offers more than double the stiffness of a comparable aluminum or glass/thermoset roof, eliminating the need for structural bows (beams) while offering greater resistance to side-impact crashes.

Pushing The Envelope

Ironically, the module's original design involved not a glossy finish but rather a textured grain. ArvinMeritor engineers initially investigated structural reaction injection molding (SRIM) because smart had already designated SRIM for other external smart car components. "But within the course of development," reports engineering director Hubert Bachmann, "we found that [SRIM] resulted in imprints on the surface from the glass fiber mats." While ArvinMeritor researched fabrication methods to overcome the print-through problem, smart's engineers upped the ante, asking for the glossy, "wet" look of a "glass-optics" finish. Bachmann recalls, "We decided to develop this technology for series-production readiness because we recognized a big potential, not only in the roof area, but also for the complete vehicle design."

Fabricating The Finish First

To achieve the glass-optics finish, the company turned to GE Advanced Materials' (Pittsfield, Mass., U.S.A.) LEXAN SLX multilayer thermoplastic film, a weatherable polymer resin system designed to replace painted and clearcoated surfaces in molded plastics. The material reportedly performs as well as or better than exterior paint systems specified by most automotive OEMs, retaining 95 percent of its gloss after the equivalent of 10 years of Florida sun exposure.

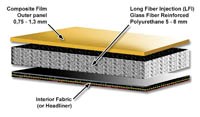

The 1.3-mm/0.05-inch thick LEXAN SLX film consists of three co-extruded layers. The outer layer is a transparent, proprietary polyester carbonate that provides the film's weather-, chemical- and scratch-resistance. A center layer of LEXAN polycarbonate holds the color effectively and provides heat resistance. The inner layer, GE Advanced Materials' CYCOLOY material, is a blend of polycarbonate and ABS (acrylonitrile butadiene styrene), which adheres well to the polyurethane in the roof module's composite inner structure. ArvinMeritor also has qualified a film product from Senoplast Klepsch GmbH & Co. KG (Piesendorf, Austria) to serve as the roof module's outer, protective shell.

GE Advanced Materials delivers LEXAN SLX film to ArvinMeritor in flat sheets, cut to size. To make the roof module shells, ArvinMeritor uses an automated process that feeds sheets through a cleaning process and then positions them over the male thermoforming tools for each roof half or a single tool for one-piece versions of the roof module (the latter is detailed in the photo series on p. 2). Each sheet then is heated to forming temperature, then drawn down over the tool and conformed to its surface by vacuum. LEXAN SLX has a "high draw ratio," which means that it can be stretched (at forming temperature) beyond 100 percent. That's enough to meet the deep-draw that is required for the roof module -- yet after thermoforming, it also retains sufficient stiffness to maintain its shape.

But ArvinMeritor also needed a deep-draw tool technology that was not yet available on the world market. As a result, the company developed a proprietary technique for optimizing the temperature profile for the part's geometry, which involved modification of both the thermoforming tool's heating system and its heating cycles.

"The temperature distribution was a critical factor for thermoforming," notes ArvinMeritor's process development manager Frank Niebuhr.

Additionally, a proprietary coating was added to each tool's surface to eliminate surface defects on the thermoformed film. As a result, the thermoforming tools now successfully shape unprecedented detail into the modules, i.e., the roof water channels, and produces a net-shape roof shell.

One Shot Fabrication

The demolded shell is then placed in a female mold (the reverse of the thermoforming tool) on the lower portion of a clamshell-like press for incorporation into the module laminates, using the Krauss-Maffei Kunststofftechnik GmbH (München, Germany) long-fiber injection (LFI) process. ArvinMeritor is only the second company to use this new reaction injection molding process, and the first to apply it to an exterior automotive component.

The Krauss-Maffei press used for the LFI process has plate dimensions of 1,400 mm by 2,800 mm (55 inches by 110 inches), big enough to handle most exterior vehicle components. The female mold and its companion male mold (mounted in the top of the press clamshell) are made from steel or aluminum, and both are heated to minimize temperature variance between the roof materials. Each roof module's headliner is positioned manually on its upper male tool.

With the outer shell and headliner positioned in the tools, inserts are hand-placed. These include wiring harnesses, mounting hardware and optional 18-mm/0.7-inch diameter steel or aluminum tubes used to increase stiffness if there are special customer requirements. The roof module is then ready for the glass/polyurethane layer.

Composite Backfilling

In conventional SRIM, operators hand lay precut or preformed reinforcement into the tool before introducing the matrix resin. By contrast, LFI automates this process and augments cost reduction by using less expensive roving rather than glass mat or preforms and eliminating waste from mat cutting.

Krauss-Maffei's microprocessor-controlled mixing head chops roving, supplied by either Mühlmeier (B0/00rnau, Germany) or Saint-Gobain Vetrotex (Lozorno, Slovakia), to specified length, within a range of 10 mm/0.4 inch to 100 mm/4 inches (fiber length used in the smart roof was not disclosed). Chopped fibers then are fed into the LFI head's mixing chamber. Simultaneously, the polyurethane components (polyol and isocyanate) are combined before entering the mixing chamber, where they wet out the fiber, and the mixture is subsequently poured into the tool. Chopping, mixing and pouring is a continuous process, during which the LFI system can adjust the mix ratio of resin and glass and, therefore, deposit different mixtures in different places within the mold. A handling robot directs the mixing head over the tool, and a focused air stream helps randomize glass orientation as the head deposits a specified quantity of material in each location.

These features enabled ArvinMeritor to program LFI to vary the thickness and glass loading so that the roof module meets structural requirements with no excess material usage. Overall fiber loading is 20 percent, but varies from 15 to 30 percent within the module, depending on structural demands. Thickness of the glass/polyurethane layer ranges from 3.7 mm to 8 mm (0.15 inch to 0.30 inch), to meet local stiffness requirements.

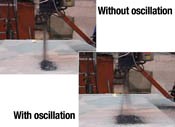

To make LFI work for the glass-optics roof modules, however, ArvinMeritor had to adjust the process. The standard LFI injection and filling operation was not consistent enough to adequately prevent entrapped air bubbles. Also, the composite mixture left the mixing head at a temperature high enough to blister the outer thermoformed shell. Working with Krauss-Maffei, ArvinMeritor engineers fine-tuned parameters such as injection head pressure and deposition pattern. Especially noteworthy, the injection head now oscillates to produce a broader, finer dispersion of the glass/polyurethane mixture. "Oscillation ensures a proper and constant polyurethane injection," Ricker says.

The polyurethane formulation also required attention. ArvinMeritor selected Baydur STR polyurethane, which is supplied by Bayer MaterialScience AG (Leverkusen, Germany), because its polyurethane formulation effectively addresses the glass-optics roof module's requirements: It maintains its liquid form long enough for LFI deposition over the whole part, yet it reacts and cures quickly to match desired production rates. The polyurethane then rises rapidly enough to meet desired fabrication speeds, but not so rapidly as to be chaotic and produce trapped air bubbles. While modifying the reactivity profile, Bayer ensured that Baydur STR's bonding properties were not compromised. The polyurethane effectively encapsulates the glass fibers and adheres well both to LEXAN SLX film and to headliner fabrics. An internal mold release ensures good self-release from the aluminum tooling. ArvinMeritor also has qualified a polyurethane produced by Elastogran GmbH (Olchingen, Germany, a subsidiary of BASF AG) for the smart car roof module.

After the LFI process backfills the glass/polyurethane composite into the female tool, the press closes and the entire sandwich structure is cured at 100 psi and 80°C/176°F for 200 seconds. Total cycle time is seven minutes per roof. Demolded roof sections are milled, deburred and tested and -- with no painting step necessary -- can be immediately sorted, packaged and shipped to the customer.

Kudos All Around

In 2002, smart manufactured more than 120,000 cars, for which ArvinMeritor provided all the roof modules, producing 30,000 per year per tool, from tools each capable of 200,000 molding cycles. ArvinMeritor Light Vehicle Systems vice president Alberto Nadal credits the success to a team effort: "The ingenuity found in our roof module is the direct result of supply-chain collaboration." Indeed, the two-piece version of the roof module took the best-of-show Grand Award at the 2003 Society of Plastic Engineers' Innovative Awards Program. Given its success, ArvinMeritor is busy prototyping the technology for engine hoods, boot (trunk) lids and pickup bed covers.

Available in 30 markets, globally, smart vehicles will enter the U.S. market in 2006.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More