SAMPE Europe 2013/JEC Europe 2013 highlights

Held concurrently, these two seminal European composites events weathered a rare Parisian snowstorm to plumb the depth and breadth of the industry.

The 34th SEICO International Conference, organized by the European arm of the Society for the Advancement of Material and Process Engineering (SAMPE, Covina, Calif.), was held, as in previous years, at the Hotel Mercure Paris (Vanves, France), a short distance from the JEC Europe event at the Paris Expo.

After an introduction on March 11 by Paolo Ermanni, SAMPE Europe president and a professor at the Swiss Federal Institute of Technology (ETH, Zurich, Switzerland), and SEICO’s technical sessions organizer Leslie Cohen, senior VP of new business development and strategic technology, HITCO Carbon Composites Inc. (Gardena, Calif.), keynoters Nick Melillo and Drew Mallow of The Boeing Co. (Chicago, Ill.) took the podium. Their topic was “Rapid Prototyping as a Tool for Technology Insertion.” Melillo explained that for Boeing’s Phantom Eye unmanned aircraft program, prototyping was key to quickly creating a functional vehicle without adversely impacting the overall program. Low-cost tooling, for example, was a must because the project budget had little room for nonrecurring costs, and the design life is short. The Phantom Eye unmanned aerial vehicle (UAV) is based on the 1980s-era Boeing Condor project that tested UAV high-altitude/long-endurance (HALE) operations, but unlike the earlier vehicle, Phantom Eye is hydrogen powered, says Mallow. The two-thirds scale demonstrator has a 150-ft/45.7m wingspan, and if it is built as an ongoing aircraft, the production model will sport a 250-ft/76.2m wingspan, with the ability to stay aloft and loiter for 7 to 10 days. The first flight was June 1, 2012. It has an all-composite, bonded wing and fuselage structure and a thermoplastic composite rudder. All parts were made out of autoclave (OOA), using OOA prepregs from Advanced Composites Group (now Cytec Engineered Materials Inc., Tempe, Ariz.), with a higher-modulus material used in the wing. KVE Composites Group (Den Haag, The Netherlands) built the rudder using polyetherketoneketone (PEKK) material, says Melillo. It weighs 10 lb/4.5 kg less than a comparable thermoset composite design. Notably, 3-D printing, a form of additive manufacturing, was used to build most of the aircraft’s smaller parts, including air scoops and wingtip fairings, which helped to accelerate the prototyping and shakedown stage. Both presenters stressed that additive manufacturing is a boon and should be more widely adopted for structural parts. In a final comment, Melillo wished for better properties in OOA prepregs — specifically, higher modulus — and called on the industry to improve virtual prototyping with computer analysis and simulation. These tools, he explained, could slash the cost of building and testing actual parts.

The Plenary session that followed, moderated by Bruno Beral, head of structure policy and development at Airbus SaS (Toulouse, France), was highlighted by the presentation of several interesting papers. Gion Barandun, affiliated with Hochschule für Technick (Rapperswil, Switzerland), spoke about his development of a composite annulus filler to replace the typical aluminum part that fills in the gap between a jet engine’s fan blades and the hub. These fillers must withstand bird strikes, foreign object damage and, particularly, fatigue, yet they must be very low in weight to reduce rotating mass. The composite deforms so much under load that the at-rest design is far different than its ultimate shape during engine operation. The fillers are currently molded by FACC AG (Ried im Innkreis, Austria) via resin transfer molding (RTM). Numerous questions from audience members indicated a high level of interest in the topic. Lars Fiedler, Airbus’ senior manager, HO R&T fuselage structure, spoke about that company’s fuselage panels designs and materials and said, significantly, “The race between metal and composites is still open.” Peter Lantermans of Fokker Aerostructures (Hoogeveen, The Netherlands) described a thermoplastic horizontal stabilizer torsion box developed under the European-funded Thermoplastic Affordable Primary Aircraft Structure (TAPAS) project. The torsion box was built via automated fiber placement and Fokker’s “butt joint” technology, in which an ultrasonic welding technique partially melts the material as it joins the ribs and skin. Airbus research engineer Emilie Luche, also involved with TAPAS, discussed methods for making thermoplastic fuselage panels with a new thermoplastic from TenCate Advanced Composites BV (Nijverdal, The Netherlands) that melts at lower temperatures. It reportedly processes more easily yet retains the required mechanical strength and in-service temperature performance.

Keynoting day two (March 12) was Dr. Olaf Täger, plastics section manager at Volkswagen Group Research (VW, Wolfsburg, Germany), who spoke about that company’s vehicle lightweighting strategy as it prepares to meet ultrastringent emissions restrictions. He announced that VW and a group of partners are building a new pilot line, with German government funding, to make carbon fiber using alternative precursors. This “Lab Factory” aims, ultimately, to develop multimaterial designs, says Täger, combining materials (including carbon fiber) in the parts themselves, using an “intelligent design” that features oriented carbon only where needed for loads. “We’re going to use Lab Factory to look at ways to improve the environmental footprint of carbon fiber,” he concludes.

Additional SEICO sessions focused on composite repair, nanocomposites in primary structure, automotive composites, structural health monitoring, automation, design/modeling and tooling.

JEC Europe 2013

At the Paris Expo, meanwhile, the JEC Europe 2013 trade show got underway. It was the biggest yet, in terms of exhibitor numbers, but a rare snowstorm on the first day put a damper on attendance. All the same, the show attracted composites manufacturing professionals of all stripes who presented, or sought, the latest in composites technology, innovation and information. HPC was there, too, and offers this quick look at some of the high points.

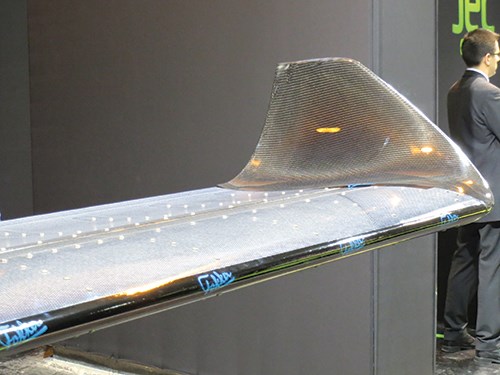

Speaking of high points, the tallest composite structure at JEC Europe was a 7m/23-ft carbon fiber multispar flap (see Fig.1) molded in one shot using the Same Qualified Resin Transfer Molding (SQRTM) process developed by Radius Engineering (Salt Lake City, Utah). Radius says SQRTM provides autoclave-like consolidation outside the autoclave. The flap was designed (but is not necessarily destined) for an Airbus A320, and it is made with Cytec 977-2 prepreg and molded in a compression molding machine built by Radius. The tool features aluminum mandrels in the core. Additional pressure, during the SQRTM process, is provided by resin injected around, but not into, the fabric by a Radius-built injection system.

Hexagon Composites (Ålesund, Norway) announced a rebranding effort that has gathered all of its business units under the Hexagon name. Three are in Norway: Ragasco AS and Raufoss Fuel Systems AS (both located in Raufoss) and Devold AMT (Langevaag). A fourth unit is in the U.S.: Lincoln Composites (Lincoln, Neb.). Each new business unit bears a common identity, and they will be referred to as Hexagon Ragasco AS (LPG cylinders), Hexagon Raufoss AS (high-pressure cylinders), Hexagon Devold AS (multiaxial fabrics and reinforcements) and Hexagon Lincoln Inc. (high-pressure cylinders). The company says that after 14 years of solid project and product portfolio growth, the unified global identity is expected to foster international expansion. In one example of that growth, Hexagon Raufoss was recently awarded a contract from a U.S. automotive OEM for the serial supply of CNG high-pressure composite cylinders to serve as fuel tanks for a model that will run on natural gas. The value of the contract is NOK 90 million ($15.36 million USD) over a four-year period.

3A Composites Core Materials (Sins, Switzerland) and Dow Chemical Co. (Midland, Mich.) announced at JEC a strategic cooperation agreement, under which they will market innovative core material solutions to the wind energy industry. The effort will focus on a new thermoplastic polystyrene (PS) foam product on which Dow has recently begun work. Dow will now partner with 3A to finish product development and then bring it to market. Dow said initial testing shows that a PS core has better mechanical properties than polyvinyl chloride (PVC) core, which is standard in wind blade manufacturing. Although its market debut is uncertain, Dow and 3A officials at the show said they are targeting a 12- to 18-month time frame.

Among the JEC Europe 2013 Innovation Awards recipients were two that had breakthroughs in thermoplastic composites. Fokker Aerostructures (Hoogeveen) and TenCate Aersospace Composites (Nijverdal) and partners were recognized for the first full thermoplastic composite horizontal tailplane (Fig. 2), used on the new AgustaWestland AW169 helicopter, which features a 15 percent weight reduction vs. predecessors made with conventional composites. The tailplane uses a composite prepreg made with Ticona Engineering Polymers' (Florence, Ky., Sulzbach, Germany and Shanghai, China) Fortron polyphenylene sulfide (PPS) and was developed jointly with AgustaWestland (Cascina Costa di Samarate, Italy), Fokker and TenCate.

Carbon fiber manufacturer Hexcel (Stamford, Conn.) held a first-day press conference that reviewed the role its materials are playing on the Airbus A350 XWB, which is expected to make its first flight this summer. Hexcel’s HexPly, HexTow and Acousti-Cap products are used in the A350’s cockpit, fuselage, vertical tail and horizontal stabilizers, wing covers and spars, wing leading and trailing edges, center wingbox, belling fairing and other parts. All told, said Hexcel officials, each A350 XWB represents more than $4 million in revenue for its composite materials. Equally newsworthy was Hexcel’s introduction of HiTape UD, a dry carbon fiber for automatic placement applications and vacuum infusion processing. Hexcel says it is targeting the material to aerostructures applications and exhibited on its stand a demonstration panel (Fig. 3) molded by Spirit AeroSystems (Wichita, Kan.) from HiTape UD.

Owens Corning Composite Materials LLC (Toledo, Ohio) announced a strategic alliance with BASF (Ludwigshafen, Germany) and TenCate Advanced Composites (Nijverdal, The Netherlands, and Benicia, Calif.). The goal of the alliance is to develop optimal solutions in thermoplastic composites for automotive mass production. According to Owens Corning group president Arnaud Genis, “There is a critical and growing need in the automotive industry to have lighter, stronger and more environmentally efficient products. Glass fiber solutions are not fully leveraged and by combining the talent and resources of Owens Corning, BASF and TenCate — all industry leaders — we will be able to take significant weight out and find the optimum solutions for our customers quickly, and with the highest quality design and structure.”

C. A. Litzler Co. Inc. (Cleveland, Ohio) announced a new hot-melt prepreg machine order that was signed at the show by Hankuk Carbon Co. Ltd. (Miryang-si, South Korea). The wide-format machine is designed for high-speed, high-quality applications and is expected to enable Hankuk Carbon to grow its prepreg business. “We are very excited to have chosen the Litzler hot-melt prepreg machine,” says president Mun Su Cho of Hankuk Carbon. “The technical and management team of Litzler answered all of the needs for our expansion in composites and with their long-time presence in Asia.”

As they did last year, automotive materials and applications took center stage, most obviously in the Innovation Awards display. There, the big attraction was the award-winning carbon fiber passenger cell (Fig. 4) of the forthcoming all-electric BMW i3 commuter car (BMW Group, Munich, Germany). Featuring carbon fiber produced in the U.S. by SGL Group (Wiesbaden, Germany), the i3 is due on the market later this year. It will be the first production vehicle to use carbon fiber in the passenger cell. The cell itself, as advertised, is an all-carbon fiber composite and, apparently, is molded in sections that are subsequently bonded together. Although there is no official word on the question of whether the i3 body panels will be carbon composites, injection molding machine maker ENGEL AUSTRIA GmbH (Schwertberg, Austria) reports that it sold two large machines to BMW for use in its Leipzig, Germany, facility “to manufacture lightweight components for car body shells.” Although ENGEL didn’t identify which car, the tea leaves can be read. The Leipzig plant is the site for primary assembly of the i3, so it is unlikely that the i3 body panels will be metal.

JEC Europe 2013 marked the first time that Cytec Engineered Materials has exhibited since the full integration of Umeco (Heanor, Derbyshire, U.K.) following Cytec’s acquisition of the firm last year. Under the Composites umbrella at Cytec, said company officials, the firm will operate in two groups: Aerospace and Industrial. Within Industrial will be a third group, Processing Materials, which will also market product to aerospace industry end-users.

In the Innovation Awards section, RocTool (Le Bourget du Lac, France) molded thermoplastic/carbon fiber covers for tablet devices, using its 3iTech compression molding technology (Fig. 5), which uses inductor coils to provide fast heating of the tool cavity and thus produce parts in relatively fast cycle times.

SGL Group (Wiesbaden, Germany), which recently acquired Lavradio, Portugal-based precursor manufacturer FISIPE SA, says it is working on converting the latter’s lines from the production of textile-grade polyacrylonitrile (PAN) to PAN suitable for the manufacture of intermediate- and high-modulus carbon fiber. SGL would not attach a timeline to this effort but said it is progressing as anticipated. SGL also introduced SIGRAFIL CSBY 70, a stretch-broken yarn processed from its 50K carbon fiber. The material is being offered in a variety of forms.

Composites Evolution Ltd. (Chesterfield, U.K.) launched glass-filled and flax-filled polyfurfuryl alcohol (PFA) bio-resin prepregs. PFA, said to be similar to a phenolic resin, is a thermosetting system derived from hemicellulose crop waste, such as sugar cane bagasse. Aside from its positive environmental profile, it has been shown to have flame-retardant properties equivalent to phenolics, along with excellent chemical resistance. The result of more than four years of extensive R&D, the high-performance PFA bio-resin prepregs are based on aligned fabrics — natural flax, glass or carbon. They reportedly boast a combination of low weight, high mechanical properties, excellent fire-retardant properties and low environmental impact. The prepregs can be consolidated by vacuum, autoclave or compression press and are designed for a range of applications in mass transport, aerospace, furniture and construction.

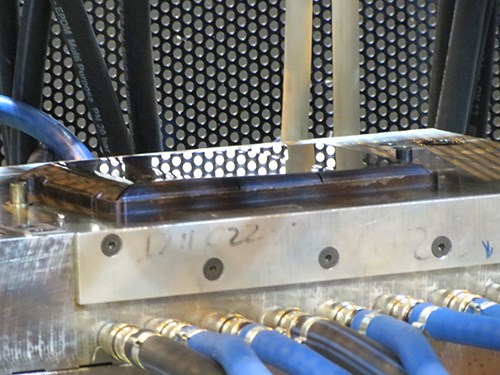

A variety of glass fiber composite leaf springs for use in car and truck suspension systems were on display. One, developed by Henkel AG & Co. KGaA (Düsseldorf, Germany) and manufactured by Benteler SGL Composite Technology GmbH (Ried im Innkreis, Austria), was molded in a specially developed RTM process (Fig. 6). Compared to conventional leaf springs made of steel, the composite springs are up to 65 percent lighter. The resin, Henkel’s Loctite MAX 2, a low-viscosity polyurethane-based formula, is said to cure significantly faster than the epoxy products usually employed in RTM, and it reportedly wets out the fiber reinforcement more easily, with less fiber displacement, enabling very short injection times. Henkel says the resin has an exceptionally high stress-intensity factor (a measure of toughness), which positively affects fatigue behavior under load and prolongs component life.

Reichhold Inc. (Durham, N.C.) highlighted its sustainability efforts, including its participation in primary industry associations to reduce the eco-footprint of composites and define safe conditions for processing them. Its recyclable resins R&D effort has yielded, for example, pipe manufacturing resins that provide 12 percent lower CO2 emissions than standard alternatives. Further, renewable resins that eliminate hazardous materials, such as water-emulsified Beckosol AQ alkyd latex resins, are said to offer superior performance to conventional solvent-borne systems. Development of low-VOC, styrene-free and monomer-free resins for advanced applications and safe-to-use resin curing systems are targeted. The company cited its participation in the RenWind Project sponsored by the Research Council of Norway (Oslo), where it aims to develop environmentally friendly and cost-efficient, high-performance, styrene-free vinyl ester resins for production of wind turbine blades.

Several other companies addressed similar efforts in presentations made at JEC’s sustainability conference. Included was DSM Composite Resins (Schaffhausen, Switzerland, and Zwolle, The Netherlands), with a focus on cobalt-free curing solutions for preaccelerating resins, and CCP Composites (Courbervoie, France, and Kansas City, Mo.), with a focus on styrene-free unsaturated polyester resins. Pergan GmbH (Bocholt, Germany) premiered its new line of Pergaquick CP accelerators based on a reportedly nonhazardous, nontoxic cobalt polymer.

Arkema (Colombes, France) and its partners PPE (Pôle de Plasturgie de l’Est, Saint-Avold, France), 3B-the fibreglass co. (Battice, Belgium) and MVC (São José dos Pinhais, Brazil) were recognized for the first new thermoplastic resin that enables the manufacture of composite parts on the same equipment and with the same processes as thermoset composites. Dubbed Altuglas Composite Solution, it employs innovative (meth) acrylic formulations that can be reinforced with continuous glass, carbon or flax fibers to form composite parts in RTM or infusion processes that are used to produce such parts with unsaturated polyester (UPR), vinyl ester or epoxy resins. The new composite can be used for aesthetic semistructural composite parts, such as shaped truck parts, bus body panels and hoods for agricultural machinery, which to date are typically made of UPR-based composites. The partners developed the first large demonstration part using a room-temperature RTM-light process. The reinforcing glass fabric, processing equipment and polymerization cycle times were identical to those used by MVC, a company well known for its expertise in the manufacture of technical composite parts, for commercial production of UPR composite parts.

Diatex SaS (Saint Genis Laval, Rhone Alpes, France) reported that it is entering the North American market. The company is starting in Canada and is looking for a U.S., specifically for its engineering fabrics. The firm has worldwide qualification for its materials from Airbus and will aim to get a similar qualification from Boeing and others, according to Diatex sales manager Christine Bourbon.

Related Content

NCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreHonda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More