SFMOMA façade: Advancing the art of high-rise FRP

The fabrication and installation of 700+ composite panels has a backstory of detailed design and careful quality assurance.

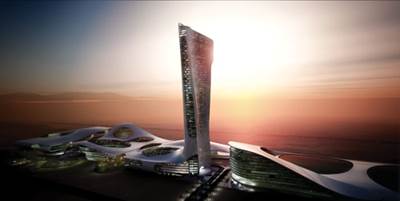

The San Francisco Museum of Modern Art (SFMOMA, San Francisco, CA, US) expansion has received a lot of press, and for good reason: It is, to date, the largest architectural use of fiber-reinforced plastic (FRP) in a US building project — more than 700 panels, some as large as 1.5m wide by 9m long, totaling 7804m2 on a contoured 10-story façade. It is the first time a composite system has passed the rigorous fire-regulation testing that permits its use above the fourth story on a high-rise exterior in the US. Missing from the accolades for this high-profile example of the rapid change in building skin technology is the manufacturing story behind the headlines: The step-by-step production process used to make and, just as important, Kreysler & Associates’ (American Canyon, CA, US) pre-production preparation for, the integrated cladding/unitized panels that helped make the SFMOMA expansion’s façade a much heralded piece of municipal art.

Design development partner

When asked how the façade construction process began, Kreysler & Associates president Bill Kreysler quips, “With over a year of design development,” referring to the fact that, increasingly, architects such as Oslo, Norway-based firm Snøhetta, the designer of the SFMOMA expansion, are choosing to enlist potential subcontractors long before anything gets built. “Subcontractors are retained through a design-assist contract,” Kreysler explains, “to work out the myriad design and construction details in collaboration with the architect.” The goal is to explore issues and alternatives during the design phase, so that once construction begins, cost and schedule targets can be maintained. Kreysler adds that it was no small matter: “We had one employee working full-time for eight months, just on this.”

To see the impact this early involvement had on the façade manufacturing process, it is necessary to understand high-rise building construction and where the FRP panels fit in. Typically, this building type begins with a foundation on which a structural frame of steel columns and beams is erected. Concrete slab floors are poured to the edges of the steel columns and beams, and in the space between the slabs, exterior weatherproof barrier walls — typically gypsum board faced with rubber — are erected. “This is pretty ugly,” notes Kreysler, “so in order to have an aesthetic finish, they put up a rain screen.”

Typically made in panels, this aesthetic veneer was the focus of Kreysler & Associates’ design-assist contract for the SFMOMA expansion. Snøhetta’s striking design of a white undulating surface, reminiscent of rippling waters in nearby San Francisco Bay, originally called for glass fiber-reinforced concrete (GFRC). “But we suggested an alternative: lightweight FRP panels,” Kreysler recounts. “At a fraction of the weight,” he notes, “they opened up another interesting option for construction.” A project’s main contractor always prefers to minimize the number of subcontractors, particularly on a part of the building that is latent with liability, such as the exterior wall, he explains. But in the design as conceived, one subcontractor would be required to install the gypsum board, another would follow with the rubber facing, then yet another would anchor a secondary steel frame required to support the heavy GFRC rain-screen panels, which would be installed by a fourth subcontractor.

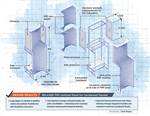

“However, our panels were light enough to be mounted onto unitized wall panels, pre-assembled off site and delivered as needed for installation.” A unitized wall system (see “The building envelope: FRP unitized façades,” under "Editor's Picks," at top right) not only offered the highest grade of weatherproof wall for this high rise, but also significantly streamlined the construction process. “The whole façade was put up under one subcontractor,” says Kreysler, adding, “Even though our system enabled the elimination of 1 million lb of steel, it turns out cutting three passes around the building was worth more.”

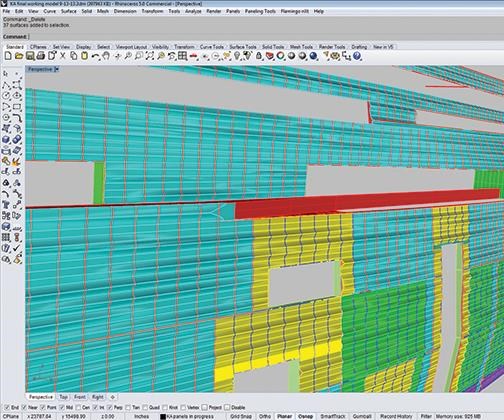

FRP’s moldability also was important. Typically, unitized panel systems — a modernized, computer-modeled update to traditional curtainwalls — feature glass or metal panels, each enclosed, typically, by a 203-mm thick aluminum frame. Frames lock together with gaskets to tolerances within 1.6 mm to form the building’s weatherproof exterior barrier with an integrated aesthetic surface. “They are great, and work well for a flat wall,” says Kreysler, “but not so much with complex, curved geometry.” So each contoured SFMOMA FRP rain screen panel would be attached to a flat backing structure — a unitized wall panel that includes a vapor barrier, insulation and weather barrier for the building. The unitized wall system fabricator, Enclos (Eagan, MN, US), also a key player in the design-assist process, worked with Kreysler & Associates to finalize specifics for attachments, joints and installation. Kreysler’s designers used AutoCAD (Autodesk Inc., San Rafael, CA, US) for construction documents, Rhino 3D (Robert McNeel & Associates, Seattle, WA, US) for 3D modeling (see Step 1, at left) and Revit (also by Autodesk) for building information modeling (BIM).

Fabrication begins

Under a design-assist agreement, a point is reached when the design is deemed ready to build, the project owner buys off on the final design with details, and the design-assist subcontractor is awarded the build contract — if it has maintained pricing and met all requirements. Kreysler explains, however, that when his company reached that point, “it was conditional upon our panels passing the NFPA 285 fire test. So that was the first thing we did.” He adds that it was not trivial to develop a composite system that would pass full-scale testing (at a cost of $100,000) with no guarantee on the outcome. Failure, however, would preclude the system’s use above the expansion’s fourth floor. “But in the end, we succeeded,” says Kreysler (for that story, see “Fire-resistant composite cladding opens endless options for designers,” under "Editor's Picks").

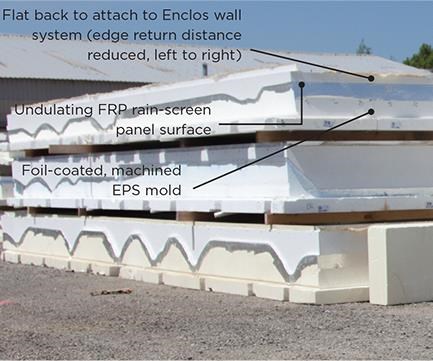

Finally, fabrication began. Because the façade would have a complex, nonrepeating and textured surface, tooling was a significant undertaking. More than 700 unique molds were CNC-machined from expanded polystyrene (EPS) foam (see Step 2). PowerMill software by Delcam (Birmingham, UK, now a subsidiary of Autodesk) translated CAD files to CNC machine tool paths. After the foam was machined, it was covered in tin foil and waxed as a mold release surface. “We then attached flat aluminum sheets on the sides to make edges for each panel,” says Kreysler. This turned the undulating foam into a rectangular box for easier handling.

Because the face of each panel would be uniquely curved, but the backs of the panels would have to be flat in order to mate and attach properly to Enclos’ flat unitized wall panels, he points out that the distance of the edge returns (i.e., from the curved front surface to the flat back surface) was not only different for each and every panel, but even for each panel’s left and right edge (see photo at left).

Gel coat was then sprayed onto each mold (see Step 3 photo, at left). The gel coat is composed of a Polynt Composites (Carpentersville, IL, US) polyester resin base, with additives for fire- and UV-resistance. Notably, a sand component is added to create a matte finish that resembles sandstone, yet also shimmers when directly lighted.

Behind the cured gel coat, three layers of woven glass fiber roving wet out with a resin impregnator were applied (see Step 4, p. 46). Kreysler used a polyester resin supplied by Ashland Performance Materials (Dublin, OH, US) and a special-order fabric sourced through distributor Core Composites (Bristol, RI, US). “We wanted an equal number of strands in both warp and weft directions, and also a custom width that matched our average panel width [1.7m],” Kreysler reveals.

Panels were allowed to cure at room temperature for several hours. But after demolding, they were postcured at 65°C for three hours in a custom-built oven. Although this is a rare step for polyester composites fabrication, Kreysler points out that in exterior applications, laminates will, indeed, postcure with sufficient time and/or exposure to temperature. “We did not want to risk that a panel not cure completely for some reason, get installed and then postcure on the building and warp,” he explains.

Pre-installation framing

Because the uncored FRP panels were only 4.8 mm thick but 1.7m wide, aluminum framing was installed on all four edges with intermediate crossmembers to stiffen the panels and serve to connect each FRP panel to its Enclos-built unitized wall-panel backing structure. Steel rods were inserted into holes drilled along the lengths of the intermediate stiffeners. A 90° elbow at the end of each rod fit into a groove in a composite attachment plate, which was then bonded to the FRP laminate using Plexus methyl methacrylate adhesive from ITW Polymers Adhesives (Danvers, MA, US, see Step 5).

The final step performed at Kreysler’s factory was sandblasting to produce a sandstone-like matte finish (see Step 6 photo). “We have used this finish on buildings for 20 years, and they still look great,” touts Kreysler. “It is easy to repair, does not oxidize easily and does not stain like concrete because it does not absorb moisture.”

After final quality assurance checks and documentation, the panels were ready to ship. Enclos leased a building in nearby Vallejo, CA — standard procedure for the company, which establishes an “assembly site” near each job site, where it receives aluminum extrusions, glass or metal panes, gaskets and attachment hardware from suppliers. Everything is computer-designed, pre-ordered to custom sizes and assembled into ready-to-install wall panels away from the job site, where quality control can be better maintained. This also reduces complexity and risk at the building site. Thus, as Enclos assembled each unitized wall system panel for the SFMOMA expansion, it received and attached the matching FRP rain screen panel from Kreysler & Associates (Step 7), producing an integrated, ready-to-install façade panel.

Kreysler points out that when Enclos loaded completed panels on a flatbed truck for shipment to the SFMOMA job site, the average 10 panels per truck was twice the number of heavier GFRC panels that could have been carried. At the job site, one of two tower cranes removed each panel and hoisted it to the appropriate location for installation. “At one point, they were installing 19 panels per day,” Kreysler recalls. “Which is why we were the first subcontractor to begin production. We had to have the necessary panels ready prior to the installation schedule.” He explains that his company could CNC-machine only four molds for the unique panels per day and knew that once installation began, panels would go up much faster than he could produce them, so he used that knowledge as the basis for calculating the production rate he could maintain for the project, then added a cushion for contingencies. “You must meet the production rate you commit to in the contract,” Kreysler points out. “If you fall behind, you can be liable not only for a delay in opening the building, but also for delaying the other subcontractors.” With monetary penalties that can easily reach six figures per day, there is little room for error.

Mitigating risk

Understanding and avoiding such liabilities, was in fact, the biggest challenge in this, the company’s biggest FRP project, says Kreysler. “We had to identify where the risk was and how to mitigate that.”

High on the list was façade color. “Color consistency was critical,” Kreysler points out. “This project would last over a year, but the gel coat color consistency was only guaranteed for 90 days. We were also adding inorganic fillers, whose colors vary. So this required a lot of effort on our part.” Long before production, the company spent significant time with gel coat supplier Polynt Composites, finalizing what the latter would guarantee in terms of color matching and then making sure that was written into Kreysler & Associates’ build contract. “We could not promise a better color consistency than the resin supplier could provide,” Kreysler notes.

The sand in the gel coat raised another concern. “There is no guarantee that one scoop would be the same color as the next,” says Kreysler. To minimize inconsistency, “we bought all of the sand for the whole job at once, paid to put it all in one hopper and tumbled it to mix out the color variation.” The sand was then bagged and inventoried, with color samples taken and recorded for every bag. Gel coat samples were made and recorded for every bag as well.

Finally, the company took 10 spectrophotometer readings for each panel to measure color consistency. That data was entered into an Excel spreadsheet and graphed to monitor variation throughout the project.

“Postcuring was similarly a matter of risk mitigation and insurance,” Kreysler adds. “By taking that extra measure, we had confidence that the variation in the panel properties was minimized to the level needed.”

Success for the future

As CW went to print, façade panel installation was nearing completion. When the exterior envelope is closed, the building contractor will finish the extension’s interior for the museum’s re-opening, scheduled for first-quarter 2016.

“Everyone is thrilled with how the project has turned out,” says Kreysler. He notes that even Enclos, which bought in early to the FRP approach and has been an excellent partner throughout, nevertheless “anticipated that our elevation would have the most problems. But ours [Kreysler & Associates and Enclos] has actually ended up having the least.” Enclos VP and SFMOMA project manager Kevin Mannen applauded the subcontractor and the use of composites: “In my 27 years with Enclos Corp., I can honestly say that I’m most proud of the SFMOMA project and it’s largely because of your FRP.”

Will this success change how composites are viewed in large architectural projects? “I think this proves the potential of composites to provide a solution,” Kreysler replies. “But I worry that companies will try to complete such projects without the significant construction experience required.” He explains that this entails knowledge about not only FRP but also contracts, insurance, working with other subcontractors, pricing, codes and regulations, movement in buildings due to temperature and seismic events and how to allow for that, to name a few key areas. “You can’t survive the cost of a serious mistake,” he warns but sees opportunities for companies willing to start with smaller projects and progress slowly, step by step.

“There are opportunities for new materials,” Kreysler sums up, “but they demand close cooperation with the building design team in order to move beyond traditional construction methods and mindsets.”

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreRead Next

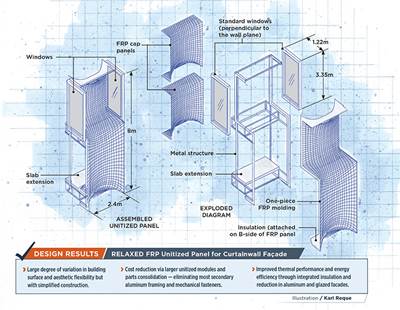

The building envelope: FRP unitized façades

New composite design reduces framing, simplifies construction and improves performance vs. conventional aluminum-framed glass curtainwalls.

Read MoreThe building envelope: Betting on the big time

Building code changes and growing architect familiarity feed more frequent composites use in large-scale commercial construction.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More