Shop practice impacts drilling success

When you're drilling holes in composites, there are many variables that must be considered. Some factors that have an impact on success are process and shop driven. The following are industry best practices that have been demonstrated to maximize hole quality and drilling efficiency with composites.

Matching the machine tool to the job can’t guarantee success (see HPC's feature article on that subject, "Hole ambitions? Optimize! Customize!" under "Editors Pick's" at upper right). Some factors are process and shop driven. The following are industry best practices that have been demonstrated to maximize hole quality and drilling efficiency with composites.

Invest in strong, stable fixturing. “The sturdier, the better,” says Peter Diamantis (AMAMCO, Duncan, S.C.). “Unfortunately, this is not always easy to do. You are always going to have vibration during a machining operation. So you have to compensate for that.” Alex Harding, COO at Cajero Ltd. (Isle of Sheppey, Kent, U.K.), notes that a properly designed fixture will support the part “beneath the drill zone to avoid spring-back on drill exit.”

Use drill motors that can sense a change in material density.Motor technology is available that can react — and change speed — when the drill tip passes through one material into another. In a composite/titanium stack, the drill slows and introduces micropecking of the metal. “CNC programming can do this automatically,” says Diamantis. “A sensor can be installed with positive drive feed motors to achieve the same result.”

Follow the prescribed drilling regime. In manual operations, “if a machinist gets tired pushing a drill, he is going to pursue a different way of drilling or using a different drill bit,” says Diamantis. “The operator will always prefer what is most comfortable. That always has to be kept in mind when trying to optimize hand operations. No matter how efficient a process is designed to be, it won’t save any money or time if the workers won’t follow it."

Techs at SECO Tools (Fagersta, Sweden and Troy, Mich.), which was acquired by Sandvik Coromant (Amsterdam, The Netherlands) earlier this year, describe a case where an optimized tool was developed for an asymmetrical composite and metallic stack. The customer, however, soon returned, complaining of premature tool wear and poor hole quality. SECO discovered that 90 percent of the holes were drilled from the top, but 10 percent were drilled from the bottom due to access issues. For those holes, of course, the materials stack sequence was reversed — the optimized tool was optimized no longer and suffered damage as a result.

Don’t stint on dust and debris removal.Recirculating debris and dust reduces tool life, creates undesirable heat and can damage part integrity, says Harding (Cajero Ltd., Isle of Sheppey, Kent, U.K.). Removing debris during drilling also saves time downstream. For example, honeycomb cells no longer need dust suctioned out or edges cleaned, potentially savings thousands of hours over the life of a program. And when one-up assemblies are drilled, the resulting increase in productivity can be lost if poor control of dust and debris forces disassembly for cleanup. Those saved hours conserve money that will easily pay for a state-of-the-art vacuum system.

“We can help here as well,” offers Harding. “We work with the manufacturer to develop machining of the whole assembly that eliminates cleanup required downstream, as well as scrap or rework, so that no disassembly is required.”

Related Content

ATL Composites collaboration advances kite-foil board production for Paris Olympics

Breiana Whitehead, pioneering Australian kite-foil sailor, spearheads board design intricacies with ATL Composites to enhance her performance ahead of the July 2024 competition.

Read MoreState-of-the-art composites cutting, machining solutions ensure accuracy, ease of operation

JEC World 2024: Compcut is presenting its advanced composites saw (ACS) and precision composite router (PCR), in addition to inviting attendees to bring their own materials for demonstration purposes.

Read MoreHufschmied Zerspanungssysteme, specialist in composites machining, establishes branch in the U.S.

Supplier of material- and process-optimized cutting tools and technology for CFRP, GFRP and CMC, as well as metals, opened its Chicago facility August 1, 2024.

Read MoreC.R. Onsrud breaks ground for machine shop expansion

Multi-phase expansion includes 9,900-square-foot addition to facility and purchase of new equipment to better serve aerospace, marine, composites and other industries.

Read MoreRead Next

Optimizing, customizing composites hole drilling

Matching the drill tool to the job can save thousands of man-hours and millions of dollars.

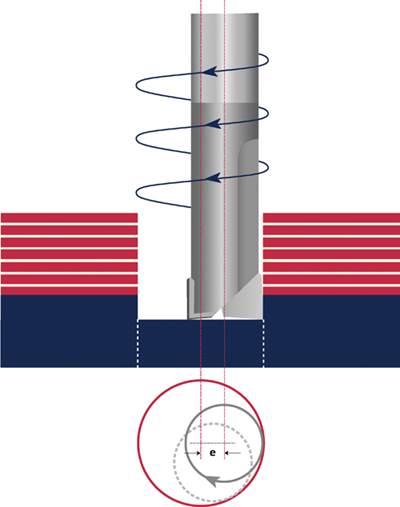

Read MoreOrbital Drilling enables “one-up assembly”

Orbital Drilling, a technology patented by Novator AB (Spånga, Sweden) offers multiple hole sizes from a single drill tool.

Read More

.jpeg;maxWidth=150;quality=70)

.jpeg;maxWidth=400;quality=70)