Simplifying the solar panel with composites

Replacing glass and aluminum with a polymer/cored polymer composite laminate ups panel durability at reduced weight.

Solar power’s history is notable for peaks and valleys. As early as 1839, certain materials were found to be conductive when exposed to sunlight. Albert Einstein weighed in, in 1905, about photoelectric effects, and the first US patent for a “solar cell” was granted in 1913. Bell Labs (now Nokia Bell Labs, Murray Hill, NJ, US) unveiled working solar cells in the early 1950s that ultimately powered US space missions.

Since then, the technology has matured and solar cell energy efficiency increased, despite a string of spectacular bankruptcies of solar startups due to a combination of overcapacity, price pressure, changing tax subsidies and credits, bad timing and/or bad luck. The past two years have seen a surge in industry growth and, importantly, solar installations. A March 7, 2017 story in The Guardian by Adam Vaughan says solar power grew 50% in 2016, reaching a global capacity of 305 GW. In the US, the Solar Energy Industries Assn.’s (Washington, DC, US) Solar Market Insight Report 2016 Year In Review reported that 2016 US solar energy installations nearly doubled compared to 2015. Further, total installed US solar capacity is expected to nearly triple over the next 5 years. By 2022, more than 18 GW of solar PV capacity will be installed annually.

“In the last decade, solar has become the cheapest source of energy,” explains Mark Goldman, CEO of Armageddon Energy (Menlo Park, CA, US). He says the cost per watt — the total solar system cost divided by the watts or power produced — has dropped from US$7 to ~US$3. “It’s true that industry has suffered,” he comments on the fates of previous players, but notes that interest in solar is still strong. “Volume continues to grow spectacularly.” Given the demand, Goldman’s company recently introduced a new, composites-intensive version of its rooftop solar panel system that is significantly lighter in weight and considerably more robust than typical solar panels.

Plug-and-play solar

“Solar panels had traditionally been produced with float glass, which provides rigidity, serves as a good moisture barrier and has good light transmission properties,” explains Goldman. Such glass, usually coated to reduce reflectivity and repel dirt, is more expensive than window glass and, in some cases, is tempered (toughened), adding more cost. Although these glass grades are less prone to breakage, they add weight, a challenge in roof-top installations, and can become cloudy over time, reducing energy efficiency. And, they must be rectangular.

Goldman continues, “Our initial strategy was to offer consumers an easy-to-install system with nicer aesthetics and a smaller overall system size, to focus less on zeroing out all of a customer’s electricity usage and more on offsetting expensive peak usage, with an average system providing 2-3 kW instead of a typical 5-6 kW.” That goal was realized by replacing glass with a thin, clear polymer film of ethylene tetrafluoroethylene (ETFE), trademarked Tefzel, from DuPont Performance Materials (Wilmington, DE, US), resulting in Armageddon’s version 1.0 panel design, SolarClover, the industry’s first film-covered solar panel to meet the solar industry UL1703 standard (Standard for Flat-Plate Photovoltaic Modules and Panels).

“We wanted to move beyond glass, and with ETFE films, our first version was light enough for a child to lift with one hand, and unique in design,” says Goldman. “The pre-wired, rapid-assembly racks were designed for installation by a roofer or electrician, with no special solar training.” One notable rooftop installation of SolarClover is the City Hall in San Jose, CA, US.

Finding alternative materials

Since that initial design, the company has continued to innovate, and has come up with a new and robust rectangular panel design. Says Goldman, “The impetus was to double-down on the things that make us different.” Those include low weight, durability, safety and the ability to produce custom panel formats cheaply. We’re a technology company, so we can’t afford to stand still.” He adds that Armageddon decided to eliminate aluminum to reduce the risk of electrical shock, reduce cost and produce a more composites-intensive design that was safer, stronger and even lighter than its first panel. The new design grew from the company’s decision to move away for the moment from residential applications and to pursue a niche providing power for commercial and military microgrids, where ease of installation and robust design are essential. He stresses that key hurdles for the panel design were to choose materials that were no more expensive than standard glass and aluminum materials, and to be able to manufacture on standard equipment, at scale: “This is a very cost-competitive market. We knew our materials, methods and associated costs, and we know where our advantages lie, but it’s still a long road.”

To realize this improved design, the company turned to its long-time partner DuPont with its requirements. Dupont introduced Armageddon to EconCore (Leuven, Belgium), a honeycomb core manufacturer that uses a high-volume, continuous process to form honeycomb panels inline from a roll of thermoplastic sheet, via a series of thermoforming, slitting and folding steps (see Learn More).

The group determined that EconCore’s ThermHex thermoplastic honeycomb panel, made of DuPont Zytel polyamide resin film, with panel faceskins made with DuPont Vizilon thermoplastic composite (TPC) polyamide sheet reinforced with continuous glass fibers in a twill weave, would create a strong and rigid panel able to replace aluminum in the structural backpanel, used for version 1.0, says Janet Sawgle, program manager at DuPont. Indeed, the EconCore ThermHex with Vizilon skins enables a cored panel product of minimal weight and high strength and stiffness, with sufficient heat tolerance to hold up to the high temperatures (up to 150°C during manufacturing as well as long-term stresses faced on roofs in the hot sun). Adds Sawgle, “We have field and lab testing underway to further demonstrate the performance of these panels.”

“The honeycomb panels are easy to work with,” says Goldman. “We can machine the features we want and shape them without the dust generation you’d get from fiberglass. They meet our 30-year weathering requirements and our application needs — fast installation and resilience in harsh, outdoor environments.”

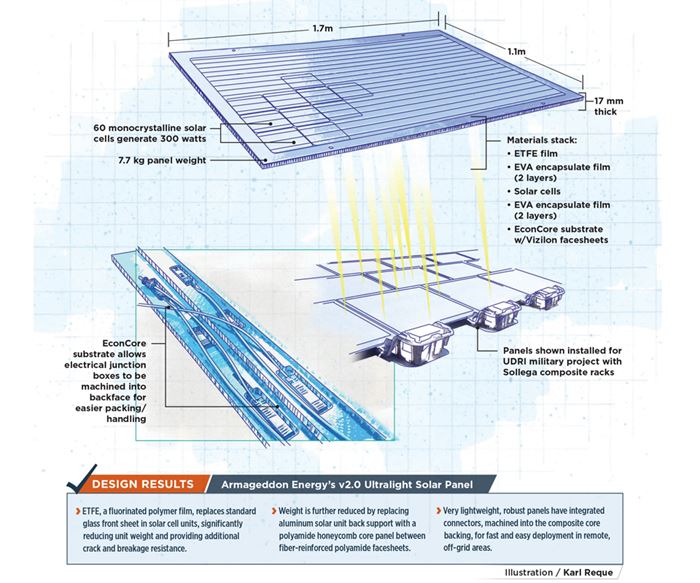

With the new support or “substrate” developed, Goldman describes how the rest of the 1.7m by 1.1m by 17-mm-thick, 300W, 7.7-kg panel comes together, a process he calls “packaging,” typical of all solar cell manufacturing: “We laminate high-efficiency monocrystalline solar cells onto our composite substrate, using encapsulants to protect the cells, typically ethylene vinyl acetate or EVA, and the ETFE frontsheet to protect the front of the panel and provide the performance advantages we want.”

Prior to being placed in the stack, the cells have been wired and connected in series. The clear ETFE is 2-5 mils thick, depending on the application, This stack is laminated in a heated press, under vacuum, for 10-20 minutes. The heat and pressure causes the EVA taken to avoid damaging the fragile cells during manufacturing. “The EconCore/Vizilon panel holds up well in the laminator, and it is even possible to thermoform it into simple curved shapes, if needed, for a specific customer. If more strength or lighter weight is required, we can specify a more heavily reinforced grade of Vizilon or a grade with carbon fiber instead of glass,” adds Goldman. He points out that the rugged version 2.0 panel can be made with a profile as thin as 11 mm. For the military project described below, a 17-mm thickness was chosen to allow for machining of pockets in the EconCore/Vizilon back panels to accommodate recessed electrical junction boxes (see photo, above).

A microgrid niche

Armageddon has worked with the US Air Force and the University of Dayton Research Institute (Dayton, OH, US) on a pilot project to show the value of rugged solar panels for military operations in off-grid areas. More than 50 of its version 2.0 composite panels were constructed for that project. “For one of the pilot systems, when UDRI used standard (glass) panels, it took the installation team two days to set up the system,” Goldman claims. “With our panels, it took 40 minutes, and the panels were less than half the weight.” Armageddon partnered with Sollega (San Francisco, CA, US), a maker of simple, off-the-shelf composite panel racking systems, to mount the panels. The speed and simplicity of the installation allowed quick panel activation.

“With lighter panels, rooftops can hold more panels, for greater power output,” Goldman points out. And, installations can be accomplished at ground level more easily and quickly, as was the case for the UDRI project. Armageddon is currently working with customers to produce bespoke designs for each installation. Goldman notes that the company has a long-term plan to develop an all-composite rack for residential rooftop installations, and to pursue partnerships with Sollega and similar companies.

Concludes Goldman, “Solar, despite its ups and downs, is now unstoppable. It will continue to grow at a startling pace for a very long time to come. Solar will vastly increase the resilience of our power and communications grids, and for the billions of people worldwide who have no access to reliable electricity, it will usher in a wave of prosperity for the people who need it most.”

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More