Small sat demonstrator enabled by CRP Technology's Windform composite materials

Selective laser sintering and CRP Technology’s Windform XT 2.0 carbon composite material was recently selected for the manufacture of a 3U CubeSat demonstrator.

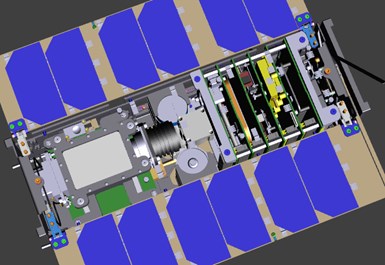

3D-printed 3U CubeSat structure via laser sintering technology using Windform XT 2.0 carbon-reinforced composite material. Source | LISA

The space industry has been revolutionized by the ever-increasing production and launch of small satellites. Additive manufacturing technologies are playing an increasing role with the manufacture of structural components for the new generation of space parts using high-performance composite materials.

Source | LISA

A recent example is a collaboration between additive manufacturing specialist CRP Technology (Modena, Italy) and the Laboratoire InterUniversitaire des Système Atmosphérique (LISA) of Universite Paris-est Creteil (UPEC, Créteil, France) on the construction of a nano-satellite that is a 3U CubeSat formfactor.

The project was carried out by students under the National Centre for Space Studies (CNES, Paris, France) and Space Campus University supervision. The goal was to develop a demonstrator that can be flight-ready in Low Earth Orbit (LEO). The engineering team at LISA and CNES used CRP Technology’s Windform Top-Line family of high-performance materials for the manufacturing of the nano-satellite, which needed to survive launch-simulating vibration tests and thermal-vacuum tests, and needed to withstand outgassing requirements.

CubeSat Structure have to fulfill launch-pad (P-Pod) requirements in terms of dimension, flatness and roughness, but also for outgassing, UV resistance, thermal expansion and general space constraints.

CRP Technology’s Windform Top-Line materials and additive manufacturing process allowed LISA to reduce mass and optimize the way to integrate parts inside the CubeSat. Source | LISA

LISA collaborated with the 3D Printing department at CRP Technology to optimize the geometries of the parts and reach the required target in terms of mass optimization and part integration. Selective laser sintering and CRP Technology’s Windform XT 2.0 Carbon composite material was chosen for the project.

Windform XT 2.0 is a polyamide-based carbon-filled laser sintering material characterized by high stiffness, excellent strength and reduced weight. According to CRP Technology, Windform XT 2.0 can replace finished parts for small-run production that are usually made with standard technologies such as injection mold, lamination of carbon fabric and metal replacement in some applications. It is said to guarantee high-dimensional accuracy and has been rated HB according to the flammability UL 94 test.

Windform XT 2.0 replaces the previous formula of Windform XT in the Windform Top-Line family of composite materials. Windform XT 2.0 features improvements in mechanical properties including +8% increase in tensile strength, +22% in tensile modulus, and a +46% increase in elongation at break. These mechanical properties have guaranteed the achievement of the required characteristics, i.e. stiffness, low mass as well as very smooth surface finish.

The CubeSat payload inside the 3D printed structure. Source | LISA

Once received the .STP file with optimized geometries was received from LISA, CRP Technology 3D printed the nano-satellite in 5-6 days, which included post-processing treated. The 3D printed part has successfully passed the control and testing criteria including vibration and thermal-vacuum testing, and has fully complied with the requests and LISA’s standards for mass reduction, component integration, outgassing control, thermal expansion and low surface roughness.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.