Styrene & cobalt: Headed for the exit?

Fair or not, styrene and cobalt are now considered harmful to humans. Here's an update on the impact this issue poses for the composites industry and what resin and additive manufacturers are doing about it.

Whether or not — and to what degree — styrene and cobalt are harmful to humans has been the subject of debate for years in the U.S. and Europe. But even a cursory inspection of the studies and data surrounding these chemicals raises more questions than answers. Because these chemicals are important ingredients in some resin systems, the composites industry has, for many years, proactively sought to protect plant floor workers from exposure via inhalation or skin contact, through the use of protective clothing, respirators and other means.

At some point, however, the health discussion — once conducted primarily among governmental agencies, academic researchers and industry — spilled over into the public arena. There, even the possibility of harm began to taint styrene and cobalt, creating a public perception that use of these materials could (or would) lead variously to cancer, disease or death. That perception alone has sometimes had enough impact to redirect current and potential customer interest toward matrix resins that don’t incorporate styrene or cobalt. In response, resin formulators have pragmatically decided that, despite the lack of real answers to the health questions, it’s time to look for styrene- and cobalt-free solutions that, for those who use their resin products, render the health questions unnecessary.

How we got to this point

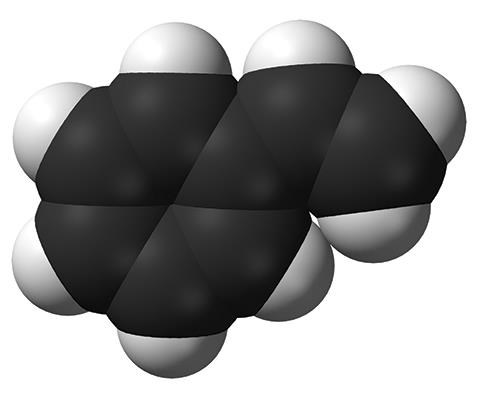

Styrene has been one of the workhorse ingredients in two of the composites industry’s workhorse resins. An effective diluent and crosslinking enabler (it readily polymerizes when exposed to light or heat), styrene is used in loadings of up to 40 percent by weight in unsaturated polyester resin (UPR) and in vinyl ester resin. Corrosion resistance and high strength have long made these resin systems popular in the manufacture of watercraft, cultured marble countertops, solid-surface bath and kitchenware, polymer concrete and more. But their heavy use in open mold processes, combined with styrene’s strong odor, have kept styrene under the wary eye of regulatory agencies as potentially detrimental to employee health.

Since the 1980s, a variety of state, national and international organizations have assessed styrene’s health effects and deemed it not harmful to humans if managed according to accepted guidelines. Nevertheless, in 2004, the U.S. Department of Health and Human Services’ (HHS) National Toxicology Program (NTP) received a recommendation from an anonymous source to reassess the health effects of styrene. The result was its decision, in June 2011, to list styrene in the 12th Report on Carcinogens (RoC), officially labeling it as “reasonably anticipated to be a human carcinogen.”

In Europe, the International Agency for Research on Cancer (IARC, Lyon, France) listed styrene as “possibly carcinogenic.” But the EU’s Registration, Evaluation, Authorisation and Restriction of Chemical (REACH) substances program proposes that styrene should not be classified as a carcinogen at all. (For a full report on “Styrene: Issues and implications," click on it under "Editor's Picks," at top right.)

Cobalt, on the other hand, has faced greater scrutiny in Europe, but less in the U.S. The focus, however, has been on cobalt metals. In a July 2013 white paper, Tony Bennett, technical development manager, Thermoset Products Americas, at Akzo Nobel Polymer Chemistry (Chicago, Ill.), summarized cobalt’s regulatory status: Cobalts used in UPRs are salts, called cobalt carboxylates, and function as promoters or accelerators, initiating gel and cure in combination with organic peroxide initiators. Cobalt naphthenate, cobalt decanoate, cobalt neodecanoate and cobalt octoate — also known as cobalt bis(2-ethylhexanoate) — are common in unsaturated polyester resins and coatings. The percentages of cobalt metal in these compounds vary.

Whatever form it takes, cobalt faces a potentially limited future in Europe and, by extension, throughout the world. Bennett reports that under REACH legislation, cobalt carboxylates were placed in evaluation by the European Chemical Agency (ECHA). In August 2012, cobalt bis(2-ethylhexanoate) was classified as CMR2 Repro-toxic. CMR stands for carcinogenic, mutagenic and reprotoxic (toxic to reproduction). It is possible that the research data could lead to cobalt carboxylate’s reclassification as CMR Carcinogenic 1b. Already in Europe, some inorganic cobalt salts, such as cobalt sulfate, have been classified as lung carcinogenic CMR 1b, reproductive toxin category 1b and mutagenic category 2. With this classification, he says, each manufacturer is obligated to demonstrate the safety of cobalt-containing products. “A CMR Carcinogenic 1b reclassification of cobalt carboxylates will be a great challenge,” Bennett says. “The effect of such legislation would restrict the use of cobalt carboxylates in manufacturing composites.”

In the U.S., cobalt, like styrene, has faced scrutiny by NTP. In October 2013, NTP issued its findings in regard to the toxicology and carcinogenicity of cobalt metal in rats and mice. The study reported that there was repeated and “clear evidence of carcinogenic activity of cobalt metal.”

Manufacturers respond

Styrene and cobalt found their way into resin formulations because they were not only highly effective, but also inexpensive and plentiful. That and familiarity has made finding replacements difficult. The composites industry, in fact, has become so dependent on these materials that any replacement, no matter how effective, is likely to be deemed inferior by some measure. Indeed, until recently, the best-performing styrene replacements that had come to market presented cost hurdles that handicapped the marketability of styrene- and cobalt-free UPRs and vinyl esters. But there is great impetus for resin formulators and their chemical suppliers to continue to pursue new, more affordable chemistries. Although there are not yet true drop-in replacements for styrene and cobalt, such a goal is within reach.

Because it’s been a regulatory target for longer, styrene has received the most attention. Researchers have sought replacements and worked to minimize styrene emissions on the shop floor. The latter, after all, is the primary concern of regulators. If styrene can be used without exposure to the workplace environment, then fabricators may continue to enjoy its benefits.

Emissions have been the strategic focus at BYK USA (Wallingford, Conn.), which 20 years ago introduced BYK-S 740 and 750, styrene emission reducers for UPRs and vinyl esters. Tom Delay, BYK’s market manager for thermosets, says the additives are used in loadings of about 1 percent or less and work as film formers that trap styrene vapors within the composite components, thereby preventing them from escaping the part and entering the atmosphere. BYK recently introduced BYK-S 760, a next-generation styrene emissions reducer that is sourced primarily (85 percent) from renewable or “green” materials. Further, 70 percent of its ingredients contain unsaturated groups, which react with the resin during polymerization. This has enabled BYK to gain food contact approval so it can be added to UPRs and vinyl esters used to mold products for food handling. Delay also claims that when the 740, 750 and 760 additives are used, “there’s no negative effect on the mechanical properties of the part and secondary bonding is not a problem.”

Replacing styrene is a more difficult task, and one that resin manufacturers have approached from several directions. One is to replace some of the styrene used in UPR and vinyl esters with materials sourced from renewable, non-petroleum ingredients. Another is to replace some of the styrene with materials sourced from other petroleum-based ingredients. The third, and most challenging, is to replace all of the styrene with an alternate petroleum-based monomer. It appears, however, that some solutions are near.

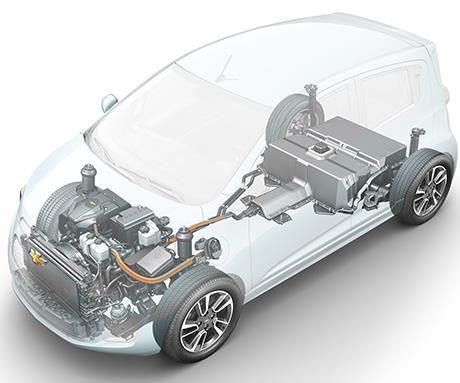

The most notable of these is ADVALITE, a new styrene-free vinyl “hybrid” just introduced by Reichhold LLC2 (Research Triangle Park, N.C.). This reactive diluent-free resin system uses standard free-radical inhibitors and initiators, offers temperature resistance of up to 200°C/392°F, has low exotherm and no VOCs, and exhibits mechanical performance on par with styrenated vinyl esters. ADVALITE was recently used in MTM 23 prepreg, developed by the Industrial Materials Group at Cytec Industries Inc. (Woodland Park, N.J.). Cytec supplied MTM 23 to Continental Structural Plastics (CSP, Detroit, Mich.) for the fabrication of a composite battery enclosure for GM’s latest electric vehicle (EV), the Chevy Spark.

Mark Steele, Cytec Industrial Materials’ technical director, says MTM 23 is not a one-for-one drop-in replacement for styrene-based vinyl esters and, thus, must be processed differently. “The only processing accommodation is related to the differential in cure temperature and final Tg,” he points out, but adds that “because there is a significant difference, parts must be cooled below the Tg of MTM 23, or supported when removed from the mold.”

As might be expected, the cost of MTM 23 is not yet on par with styrene-based vinyl esters: “Styrene is an extremely low-cost monomer,” reports Steele. “The components used to formulate MTM 23 do not have this low-cost base, so it is inevitable the manufacturing costs will be higher.”

But Cytec argues that the proof of MTM 23’s value is in the end product. GM’s battery tray met a number of rigorous performance requirements, including 30° offset-barrier, side-impact, and rear-barrier crash; 50G impulse shock (x, y, and z); post-crash package integrity; fire-resistance testing; 3m/10-ft drop testing (bottom/end); a 1m/0.91-ft water-submersion test; and vibration/shock testing. Moreover, the compression-molded structure is 40 percent lighter than metallic solutions.

Cytec and CSP also worked together on data generation, ply design and press production technology. That collaboration enabled CSP to manufacture parts in cycles of less than 10 minutes at a 150°C/300°F cure. Cytec, however, contends that MTM 23 has the capability to be rapid-cured in less than three minutes.

Resin manufacturer AOC Resins (Collierville, Tenn.) has packaged its styrene-free resins in its EcoTek line, with particular emphasis on underground sewer pipe rehabilitation applications. In the line is the EcoTek L704-FAHG-VT Series, a set of high-molecular-weight isophthalic/unsaturated polyester resins thinned with vinyl toluene. Another, EcoTek H164-ACAG-40, is a medium-reactive, styrene-free, thixotropic, prepromoted resin, designed for use in the manufacturing of boats and other composite parts via hand layup or sprayup.

In 2007, Reichhold introduced POLYLITE 32245, a line of low-styrene (less than 35 percent) casting resins, formulated as alternatives to orthophthalic-based resins used in engineered marble applications, such as integral bowl vanities and bathtubs. This medium-reactivity resin line’s low viscosity reportedly allows higher filler loadings than conventional casting resins, thus reducing material costs, and is formulated for use with lightweight fillers, including carbonates. The resins are prepromoted for room-temp cure, using methyl ethyl ketone peroxide (MEKP).

Dixie Chemical Co. Inc. (Pasadena, Texas) formulates bio-based unsaturated polyesters (ortho-, iso-, and terephthalic, DCPD-modified and bisphenol A fumerate) and vinyl esters. In 2012, the company launched a bio-based partial styrene alternative for UPR and vinyl ester. Dixie’s composite applications chemist Alex Grous says the methacrylated fatty acid (MFA)-based reactive diluent is derived from palm kernel and coconut oil. It is used in sheet molding compound (SMC) and bulk molding compound (BMC) and in resin systems designed for pultrusion, casting and resin transfer molding (RTM) processes. Applied in 15 to 18 percent loadings, MFA offers styrene emissions reductions of up to 27 percent, with good toughness and elongation, low-to-no odor and 60 percent bio-content.

Dixie has worked with partners Ashland, LLC, Premix (N. Kingsville, Ohio) and the Maine Composites Alliance (Portland, Maine) to develop parts and structures made with resins formulated, in part, with MFA. The Alliance recently assessed data on MFA loadings of 15 percent in vinyl ester for a construction application, and 18.6 percent in polyester for a marine application. Infusion times were either unchanged or slightly improved, Grous claims, with no sacrifice of toughness, flexural strength or other mechanical properties.

Cobalt replacement for composites applications is less evolved than styrene replacement is, but activity is starting to pick up. Among the most active is AkzoNobel, which began looking at alternatives a few years ago, mainly among other metals on the periodic table that are similar to cobalt. Copper in its natural state, Bennett says, actually hinders resin cure, but AkzoNobel found that if it was “excited” properly, it could be used to promote cure. This led to the development in 2006 of two copper-based compounds to promote cure of polyester resin, and one manganese-based compound that appears to function like cobalt does in parts for some high-temperature applications.

Bennett says that about this same time, two other companies were working on similar technologies, OM Group (Cleveland, Ohio), a manufacturer of chemicals, metals and other advanced materials, and DSM Composite Resins (Schaffhausen, Switzerland), a well-known manufacturer of matrix resins. Each company had filed patents relative to cobalt replacement and, Bennett says, there was much overlap in terms of cobalt replacement R&D. “We decided that we could continue to work alone, and block each other, or work together,” he notes. As a result, an agreement between DSM and AkzoNobel was made, creating the BluCure product line and opening cobalt replacement technology, commercially, to the composites market.

Introduced in 2013, BluCure is administered by AkzoNobel and licensed to resin manufacturers or processors, who incorporate it into nonpromoted resins. So far, there are several licensees in Europe and one in the U.S.

Not always exact drop-in replacements, BluCure products “can require a little effort to match cobalt performance,” Bennett says, depending on the application and the manufacturing process. “But new cure systems developed by AkzoNobel can surpass cobalt properties in some instances.”

This is a product, however, developed in anticipation of more stringent REACH restrictions, which Bennett and other cobalt replacement enthusiasts believe are imminent. “There has not yet been a compelling reason to change, but the new BluCure technology shows improvement over cobalt in more challenging curing applications where traditional cobalt has limited effectiveness.”

The ultimate regulatory fate of styrene and cobalt is unknown, but it is well understood in the specialty materials world that once a chemical lands on a regulatory “list” and is labeled, rightly or wrongly, as definitely or potentially carcinogenic, getting it off that list is almost impossible. Resin manufacturers understand this, so we can expect more aggressive development of styrene and cobalt alternatives.

Click here to view a letter about this article from John Schweitzer, vice president, government affairs, American Composite Manufacturers Association (Washington, D.C.).

A. Schulman Inc.

Related Content

XlynX Materials BondLynx and PlastiLynx for low surface energy PP, PE substrates

Award-winning Xlynx materials use breakthrough “diazirine” technology to boost bond strength up to 950% as adhesives, primers and textile strengtheners.

Read MoreHenkel releases digital tool for end-to-end product transparency

Quick and comprehensive carbon footprint reporting for about 58,000 of Henkel’s adhesives, sealants and functional coatings has been certified by TÜV Rheinland.

Read MorePro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

Read MoreFilm adhesive enables high-temperature bonding

CAMX 2024: Aeroadhere FAE-350-1, Park Aerospace’s curing modified epoxy, offers high toughness with elevated temperature performance when used in primary and secondary aerospace structures.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More