Taking the hit without added weight

High-modulus polypropylene (HMPP) fiber hybrids graduate from tennis to ... tornados!

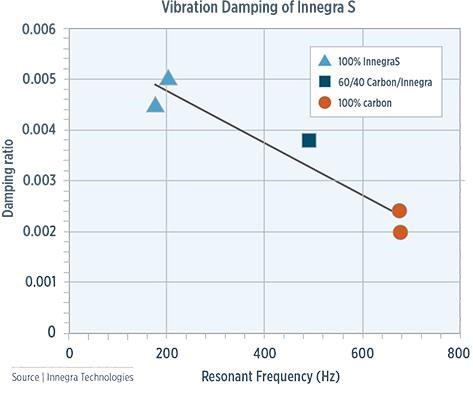

Although high stiffness and strength at very low weight have made carbon fiber (CF) a mainstay in high-performance sporting goods, athletes now also desire vibration damping, which improves athlete control and reduces fatigue. This trend toward a better “feel” — a quality CF cannot provide on its own — created a niche for Innegra, the tradename for high-modulus polypropylene (HMPP) fiber produced by Innegra Technologies (Greenville, SC, US). An early adopter was HEAD Sport (Kennelbach, Austria). Tennis players valued the energy absorption HMPP added to HEAD’s carbon fiber racquets: HEAD has measured a 17% reduction in vibration in its hybrid HMPP/CF racquets, which are now a standard product line, reports Innegra Technologies’ business development director Jen Hanna. Surfers appreciated HMPP’s ability to keep their fiberglass boards from breaking. Similarly, HMPP in Adventure Technology’s (Greenville, SC, US) whitewater kayak paddle shafts significantly reduced catastrophic failure and increased abrasion resistance by 200% in the paddle’s glass fiber blade.

“What we’re seeing,” Hanna emphasizes, “is a real push for increased toughness, durability and vibration damping, but without sacrificing light weight.”

Innegra also iced a spot in the National Hockey League (NHL). A hybrid HMPP/CF fabric and a special resin developed for Bauer (Exeter, NH, US and Mississauga, ON, Canada) was used in Bauer goalie sticks for years. NHL players suggested applying the hybrid fabric in goalie masks, which must withstand multiple hits per game from 100-mph pucks. HMPP reportedly dissipates energy very quickly, with a sonic velocity — the rate (m/sec) at which energy is dispersed in ballistics testing — near that of more expensive aramid fiber. “The players say they don’t get the ringing in their ears that they do with the normal masks,” says Hanna. “You could build up more toughness and durability with more CF layers,” concedes Hanna, “or with plastics like nylon, but this also means adding weight.” She says HMPP offers a higher elongation-to-break than CF while offering a higher modulus than either standard PP, polyethylene (PE), or polyamide (nylon). And although HMPP is hydrophobic, like ultrahigh-molecular-weight PE (UHMWPE) fiber, it has enough surface roughness to enable good bonding, which the UHMWPE’s slick surface makes difficult.

“Innegra really excels in applications that have to take a lot of abuse,” says Hanna. That was not lost on Tornado Pod (Dallas, TX, US) founder Wes Kouba. Seeing what Innegra hybrids had achieved in the sporting goods world, he sought to use the fiber in his cost-effective, compact alternative to traditional storm shelters. His TornadoPod uses a submerged 1.5m-diameter PE unibody, anchored to the ground with poured concrete, to accommodate up to six adults, and a slidable hybrid glass/HMPP fiber composite dome that extends almost 1m above ground to permit easy entry and exit. The dome has been tested to Federal Emergency Management Agency (FEMA, Washington, DC, US) standards, for which certification testing includes four 100-mph impacts from wooden two-by-fours fired from a cannon at close range. “The two-by-fours just bounced off the dome,” recalls Innegra Technology chief composites engineer Russ Emanis.

View a video of the TornadoPod testing online: short.compositesworld.com/tornadopod

Related Content

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More