The Double-Notch Shear test specimen for composite materials

Dr. Donald F. Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) recommends best practices for double-notch shear test specimens.

A shear test method for composite materials, typically termed Double-Notch Shear, has been in existence for many years and is still used, but not without controversy. It is defined by ASTM International’s (West Conshohocken, Pa.) “Standard Test Method for In-Plane Shear Strength of Reinforced Plastics” (ASTM D 3846). Even its title is controversial because it is not an in-plane shear test, but rather an interlaminar shear test. That is, it measures the through-the-thickness shear strength of the composite, just as the Short Beam Shear test method (ASTM D 2344) does. Presumably, the two test methods should produce the same shear strength values. But they don’t.

A third shear test method, commonly called the Iosipescu Shear test method (ASTM D 5379), is primarily used for determining in-plane shear properties, but it can also be used to determine interlaminar shear properties. ASTM D 5379 is officially known as the V-Notched Beam Method because ASTM prefers not to use proper names (Nicolae Iosipescu of Romania is the original developer of the method). The result is confusing: we have both a Double-Notch Shear test method and a V-Notched Shear test method that — despite the fact that the V-Notched specimen also has two notches — are totally different in their operating principles.

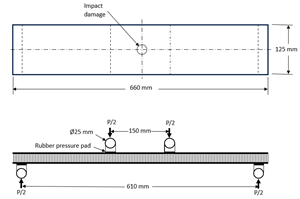

The Double-Notch Shear test specimen geometry is shown in Fig. 1. Because the fiber reinforcement in the composite specimen is presumably planar, and its principal axis is along the specimen axis, planes of low shear strength will be present, including the plane that is parallel to the bottoms of the two opposing notches. When an axial compressive end loading is applied, a shearing action is induced along the specimen centerline between the notch roots, presumably leading to a failure on this shear plane. The area of this shear plane is LxW.

Originally, a specimen of similar geometry was loaded in tension and governed by ASTM D 2733, “Standard Test Method for Interlaminar Shear Strength of Structural Reinforced Plastics at Elevated Temperatures,” introduced in the late 1960s. Note that its title correctly identifies it as an interlaminar shear test method. ASTM D 3846, introduced in 1979, changed the loading method to compression, and ASTM D 2733 was subsequently withdrawn in 1981.

Its inaccurate title aside, the ASTM D 3846 standard’s shift to compressive loading is advantageous because a tensile loading induces a through-the-thickness tensile normal stress in the specimen on the shear plane between the notches, but compressive loading induces a compressive normal stress in this same region. In typical composite materials, the interlaminar (through-the-thickness) tensile strength is not nearly as high as the interlaminar compressive strength, so a tensile loading can cause a premature tensile failure before the desired shear failure.

Because the relatively thin specimen, as shown in Fig. 1, will likely buckle when loaded in compression on its ends, it must be laterally supported. ASTM D 695, a standard plastics compression test method in existence since 1942, features lateral supports to prevent buckling. The authors of ASTM D 3846 adopted the same specimen length used in ASTM D 695, so the same lateral supports could be used in both methods. This made the new shear test method more attractive for potential users because ASTM D 695 test fixtures were generally available.

Unfortunately, the fundamental problem with the Double-Notch Shear test method is that significant stress concentrations occur at the roots of the notches, resulting in premature failure. A number of studies of specimen geometry modifications have been performed over the years in an attempt to eliminate or significantly reduce these stress concentrations, but with little success. (A detailed summary of these works, including both numerical and experimental results, was compiled by Jiang and Adams.1)

The various studies indicate that there is no significant influence on the magnitude of the notch root stress concentration when the notch spacing is increased (the L/T ratio, see Fig. 1), but there is a significant influence on the measured average shear strength.2 That is, the stress concentration (the maximum stress) remains relatively constant. But because the shear area (LxW) increases as L increases, and the experimentally determined shear strength is defined as the applied force at failure divided by the shear area, the (apparent) shear strength decreases. This is the (average) shear strength that is measured experimentally. But the more meaningful value is the maximum shear stress at the notch tip stress concentrations, where failure occurs. Therefore, the L/T ratio should be kept low.

Analyses and experiments suggest values of 1.0 or less, so the measured (average or apparent) shear strength will be close to the maximum (actual) shear strength.2,3 Essentially, the distance between the notches should be equal to or less than the specimen thickness. Note that in ASTM D 3846, the allowable L/T ratio can range between 1.0 and 2.5. Based on the discussion thus far, the lower limit of that allowable L/T ratio range should be used.

Notch depth is another consideration. In theory, each notch should be one-half the specimen thickness to create a shear plane through the notch roots. But because it is difficult, in practice, to ensure that each notch is exactly one-half the specimen thickness, ASTM D 3846 allows each notch depth to be slightly more than one-half (but not less) the specimen thickness. Studies indicate that these slightly deeper notches do not significantly influence the results.

Interestingly, the rectangular-shaped notches, even with sharp corners as shown in ASTM D 3846 (although not explicitly defined there), appear to be desirable. Studies of alternate notch shapes, including fully radiused notch roots, have verified this.

One final geometric parameter to consider is notch width (w). The ASTM standard suggests a relatively narrow allowable range (1.0 to 1.7 mm/0.04 to 0.07 inch). However, both numerical and experimental studies indicate that increasing w by at least a factor of 10 is beneficial. The maximum and the average shear stress are increased on the order of 10 percent. This is significant because the Double-Notch Shear test method inherently produces lower shear strength values than the other methods. For example, it was noted earlier that the Short Beam Shear test method also provides interlaminar shear strength values. The Double-Notch Shear test tends to produce shear strengths on the order of 25 percent lower, and with much more scatter.

In short, the Double-Notch Shear test method has little to offer and should be avoided.

References

1Jiang, W., and Adams, D.F., “Evaluation of the Short Beam Shear and Double Notch Shear Test Methods for Composite Materials,” Report UW-CMRG-R-99-108, University of Wyoming (Laramie, Wyo.), Grant No. 94-G-009 by the Federal Aviation Admin. (Atlantic City, N.J.), September 1999.

2Markham, M.F., and Dawson, D., “Interlaminar Shear Strength of Fibre-Reinforced Composites,” Composites, July 1975, pp. 173-176.

3Dadras, P., and McDowell, J.S., “Analytical and Experimental Evaluation of Double Notch Shear Specimen of Orthotropic Materials,” Experimental Mechanics, June 1990, pp. 184-189.

Related Content

Photothermal tomography for locating, quantifying defects in composites

Years of infrared testing development result in thermography technology that is no longer just qualitative, but can define defect size and depth, making additional UT scans obsolete.

Read MoreCrashworthiness testing of composites: A building block approach, Part 1

Determining the crashworthiness of composite structures requires several levels of testing and analysis, starting with coupon-level crush testing.

Read MoreDamage tolerance testing of sandwich composites: The sandwich flexure-after-impact (FAI) test

A second new ASTM-standardized test method assesses the damage tolerance of sandwich composites under flexural loading.

Read MoreTesting to support composite bolted joint analysis

An overview of ASTM Standard Guide D8509, and its coupon-level mechanical testing of design properties for analyzing composite bolted joints.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More