Tour of ORNL’s Manufacturing Demonstration Facility

3D printing was the focus during the tour of the ORNL facility in Knoxville, TN.

Before Carbon Fiber 2015 kicked off in Knoxville, attendees had an opportunity to visit the ORNL Manufacturing Development Facility (Oak Ridge). Developments at ORNL include Big Area Additive Manufacturing, or BAAM, new technology and carbon fiber composite materials. The facility is working to create innovative solutions for applications in manufacturing, transportation and more. This time around the tour focused specifically on ORNL’s 3D printing capabilities and here are some highlights:

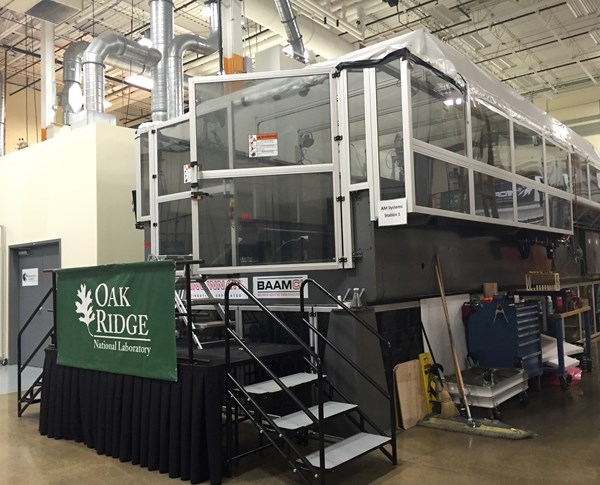

A look at the supersized 3D printer

ORNL is home to the world’s largest polymer 3D printer: the Cincinnati Incorporated BAAM system is capable of printing 100 pounds of polymer material per hour in sizes up to 20 feet long, 8 feet wide and 6 feet tall. The equipment is part of an on-going partnership between ORNL and Cincinnati to lower cost and increase speed of 3D printing. BAAM generated a lot of attention thanks to the Shelby Cobra, which was design and manufactured in just six weeks. The 635-kg car includes 227 kg of BAAM-printed parts, using a chopped carbon fiber-reinforced ABS provided by Sabic.

A look at AMIE

We also got to check out a really interesting project ORNL is working on that combines clean energy technologies into a 3D-printed building and vehicle. It is designed to showcase a new approach to energy use, storage and consumption.

The Additive Manufacturing Integrated Energy (AMIE) demonstration seeks to become a model for energy-efficient systems that link buildings, vehicles and the grid.

An ORNL team worked with industrial partners to manufacture and connect a natural-gas-powered hybrid electric vehicle with a solar-powered building to create an integrated energy system. Power can flow in either direction between the vehicle and building through a lab-developed wireless technology. The approach allows the car to provide supplemental power to the 210-square-foot house when the sun is not shining. Carbon fiber-reinforced ABS was used for about 80% of the house components and 30% of the car. Both the car and house were 3D printed using ORNL’s BAAM process.

The 38x12x13-foot building was designed by architecture firm Skidmore, Owings, and Merrill (SOM) through the University of Tennessee-ORNL Governor’s Chair for Energy and Urbanism.

A couple other photo highlights:

Research into reducing the cost of materials - such as carbon fiber - is a priority of ORNL.

This car hood was signed by President Obama and Vice President Joe Biden during their tour of ORNL.

Related Content

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.