Truck bed lid covers it all

Tonneau cover manufacturer hits elusive aesthetic and performance targets with molded-in-color thermoplastic capstock and glass/polyester structural laminate.

Engineering challenge:

Design a hard tonneau cover with a more durable Class-A surface that can be color-matched to pickup truck body color, with a strength-to-weight ratio that eliminates the need for intrusive underbracing, conserves aerodynamics-based fuel-efficiency gains, permits one-person installation and removal, and is constructed by a method that prevents past problems associated with exothermic adhesive bonding.

Design solution:

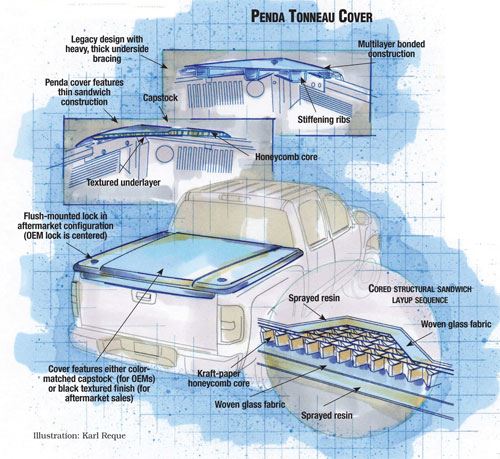

Comold a previously thermoformed high-gloss, five-layer, color-matched thermoplastic capstock — which eliminates the need for painting by in-corporating multiple color layers and a protective clear, high-gloss surface layer — and a wet-laid, lightweight, low-profile, honeycomb-cored thermoset sandwich understructure that requires no secondary bonding.

Tonneau covers, available in hard and soft versions, are among the most popular accessories for pickup trucks. For the truck owner, a covered bed reduces air turbulence and, therefore, the vehicle’s drag coefficient, which has the potential to improve fuel economy. In the case of the durable hard tonneau covers, the accessory also provides lockable, dry storage to protect valuables kept in the bed. For the truck dealer and auto-aftermarket supplier, the covers have been a welcome revenue source.

Traditional hard tonneau cover designs, however, have delivered less-than-promised performance. The earliest covers were open molded via spray-up, typically using glass-reinforced polyester, and painted in a secondary operation. The two-step process was expensive and the paint was prone to scratching and chipping. More recently, the use of compression-molded sheet molding compound (SMC) reduced cycle time, but the resulting covers were heavy enough to cancel out much of their aerodynamic gain and, like their predecessors, were difficult for one person to install or remove. Available only in a textured black finish, SMC covers last longer than painted competitors but also take color out of the sales-appeal equation.

Attempts to resolve these problems with thermoplastics and new designs created new problems. Most thermoplastic systems feature multiple layers of thermoformed monolithic ABS sheet (with or without acrylic capstock) that are adhesively bonded together. To meet stiffness requirements across such a large horizontal expanse, part designs were deeply ribbed and, therefore, thick (typically 2.5 to 3.0 inches/64 to 76 mm in the center) and they required underside metal bracing to avoid sag. The bracing intruded even further into the bed, reducing cargo-carrying capacity. Additionally, ribs and bracing made it challenging to carpet the underside of the tonneau cover, a popular option for dressing up the unit. Further, the temperature required to bond the two-part adhesive used to tie layers together tended to distort the capstock (when used) and frequently led to read-through of the bottom layer. Fit/finish, durability and cosmetics also were at issue.

Several years ago, Penda Corp. (Portage, Wis.), a supplier of fiberglass tonneau covers, drop-in bedliners and other pickup accessories, began to study the bed-accessories market for new opportunities. “It was clear this segment hadn’t kept pace with the revolution we were seeing in the rest of the light-truck market,” says Tim Williams, VP, Automotive at Penda. “Bed accessories at that time neither offered the versatility and functionality that OEMs were designing into their vehicles nor provided the ease of use, high styling, and extra features that consumers were demanding.” A number of composite tonneau covers had been offered through aftermarket retailers, but Penda was the only company that supplied covers to OEMs (under the MOPAR brand) because automakers’ rough-road durability tests were so severe that other systems failed during testing. Penda saw an opportunity to design and build a truly tradeoff-free hard tonneau.

Taking the “clean sheet” approach, the Penda team began with a wish-list of features considered valuable to OEMs and consumers: higher styling with the option, for the first time, to exactly match body paint; low mass to improve fuel economy and ease installation/removal; a more secure but still easy-to-use locking system; a stiffer, stronger but lower-profile design that wouldn’t restrict storage space; and a hinge system that allowed for easy removal of the unit when larger payloads were hauled. Penda engineers also benchmarked competitive systems (four sprayup fiberglass, two SMC and three thermoplastic) to explore which features and benefits should be considered for the new design.

Capstock contributes color

High on the wish list was the team’s desire to match precisely the cover’s color to the truck’s body color. The team wanted to try molded-in color (MIC), a system that, in Penda’s previous work with multilayer acrylic capstocks on TPO lawnmower hoods and ABS golf-cart bodies, not only met aesthetic goals but proved more durable than paint. Fortunately, Penda’s new president and CEO, Ulf Buergel, had a strong relationship with SENOPLAST Klepsch & Co. GmbH, (Piesendorf, Austria), a major supplier of automotive MIC technology in Europe. In collaboration with SENOPLAST, Penda developed a 0.120-inch/ 3.05-mm thick co-extruded, five-layer thermoplastic sheet: clear acrylic + colored acrylic + colored ABS + PC/ABS + colored ABS. The use of multiple layers of translucent MIC color (including optional metallic flake) ensures excellent distinctiveness of image (DOI) while the clear top layer provides a high-gloss shine and provides protection for the color layers underneath. Because SENOPLAST had recently started a new operation in Mexico, this capstock could be produced there in flat sheet form and then shipped to Penda for forming.

With the decorative capstock supply line in place, the next challenge was to develop a structural base onto which the capstock could be bonded and into which mounting and locking hardware would be fastened. The team wanted to meet OEM rough-road performance targets yet optimize storage space. Penda needed a solution that would possess a significantly higher modulus than thermoplastic designs to permit fabrication without thick ribs or underside bracing. To prevent underlayer read-through and distortion of the capstock, the team sought an alternative to the exothermic adhesive-bonding process used with existing thermoplastic tonneau systems. Another concern was managing coefficient of thermal expansion (CTE) differentials between the unreinforced, multilayer thermoplastic capstock and whatever technology was chosen for the high-modulus underlayer.

Core thins cross-section

Penda’s experience with its traditional fiberglass covers led them to adopt a conventional sandwich construction but use an unusual method for its fabrication, which combines elements of traditional sprayup with a different take on vacuum bagging. Kraft-paper honeycomb (Tricel Honeycomb Corp., Gurnee, Ill.) is sandwiched between skins of random glass mat (from Jushi Fiberglass, in Tongxiang, China), impregnated with black-pigmented, unsaturated polyester from CCP - Cook Composites & Polymers (Kansas City, Mo.). Materials were supplied through distributor Composites One (Arlington, Hts, Ill.).In production, the capstock is first vacuum-formed over a water-cooled, aluminum male mold. Every model of every vehicle uses a slightly different cover design and, thus, requires a different tool. The forming process temperature and time differ for each, based on the tonneau tool/design and — because differently pigmented materials absorb heat at different rates — the color of the material in the capstock.

Then the capstock, the structural sandwich components and a thermo-formed black, PC/ABS underlayer are comolded in a bonding buck, with the capstock doubling as the tool face. First, the thermoformed MIC capstock is laid exterior face down in the bottom of the buck. Next, a layer of neat resin is hand sprayed onto the capstock. Glass mat is placed over the wet resin layer, followed by the honeycomb and another layer of glass mat. At key locations in the polyester/glass/honeycomb/glass/polyester stack, Penda also layers in metal reinforcement points, latches, locks, and other hardware. Finally resin is sprayed over the top glass layer, and the PC/ABS underlayer is positioned over the layup, textured surface up.

The fixture is sealed not with conventional bagging film and tape but instead with shrink-wrap, and a vacuum is pulled to consolidate the laminate and ensure that the resin fully wets out the mat. Ceramic heaters positioned above the unit bring the part temperature to 100°F/38°C. Here, the potential for CTE mismatch is minimized by controlling resin gel time, allowing enough working time to finish the assembly and place the unit under vacuum before setup of the resin begins but avoiding too long a delay, which also could cause problems. The pressure and temperature are held for 20 minutes to cure the polyester and evacuate air between the capstock and structural layers to prevent substrate read-through. The specially formulated polyester bonds to the ABS bottom layer of the capstock and PC/ABS underside face layer, forming an integral, virtually unbreakable joint that leaves no witness marks and eliminates the cracking/delamination seen in adhesive-bonded systems.

The demolded part is trimmed, finished and then, instead of the traditional cotter-pin hinges used on previous designs, Penda installs its patented quick-release V-Hinge system, which enables the truck owner to remove or install the cover in seconds. Every tonneau is inspected and test fitted on the proper-size truck bed before it is shipped.

Tonneau hits targets

The cover has proven to be a significant improvement over legacy systems. At the dealership, the new cover’s simple mounting system speeds installation and eliminates fit-related returns. Most dealer-prep technicians can install one in 20 to 30 minutes. For the truck owner, it overcomes performance and appearance shortcomings of previous designs. Al-though it is slightly thicker, at a nominal wall of 1.25 inches/32 mm, than the typical glass-reinforced thermoset unit, the new cover is only half as thick as thermoplastic systems and weighs less than any previous technology — 25 to 37 percent lighter than comparably sized fiberglass units. Its lower weight and patented hinge system enable most truck owners to remove the cover in seconds and carry the unit by themselves. The system also provides greater lid-opening height thanks to longer struts. Unlike conventional tonneaus with inexpensive protruding locks, the Penda cover’s recessed single-lock/twin-point latching system with slam-latch functionality is less prone to damage, looks better and is more reliable.Aesthetically, Penda’s color-matched capstock is a big win: Its high-gloss, Class A surface has excellent DOI, very high resistance to UV degradation, and color stability to 5,000 kJ of Xenon-arc exposure (SAE J1960). Penda reports readings in the high 80s for gloss and low- to mid-80s for DOI — values that are higher than paint and account for the mirror-like finish. Further, scratches in the capstock’s clear top layer can be buffed out without color loss, reducing maintenance issues. The cover’s broad thermal resistance (85°C to -30°C/185°F to -22°F) helps the cover resist cracking.

Cover commands market

The robust system is only the second ever to pass OEM rough-road durability tests, so Penda is still the only supplier providing OEM tonneau covers and the first ever to offer them in body-matched, molded-in colors. The company has phased out its fiberglass tonneaus in favor of the new technology. It currently supplies color-matched OEM tonneaus for General Motors Corp.’s short and regular bed GMT900 Silverado/Sierra and compact GMT355 Colorado/Canyon pickups and has recently launched full-size tonneaus on Ford Motor Co.’s ’09MY F-150 pickups. Penda also supplies full-size, color-matched tonneaus for Toyota Motor Co.’s Tundra. Aftermarket versions with a textured-black surface are available under the brand Penda Venture. A third-generation product that will offer MIC capabilities in a less-costly system is under development.Related Content

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreSMC simulation tool enhances design optimization

CAMX 2023: FiRMA, Engenuity’s new approach to SMC, uses a predictive technique that accurately reflects material properties and determine the performance range an SMC part or structure will exhibit.

Read MoreAOC introduces UV-Resistant Automotive System for SMC parts

AOC’s novel formulation, tested in the lab and in real-world environments, delivers a deep black, molded-in color that resists fading and offers high scratch resistance.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)