VABO Composites: Dutch innovator excels in diverse applications

From yacht masts and ship doors to front loader buckets and architectural projects, VABO uses resin infusion and ingenuity to push composites forward vs. metals.

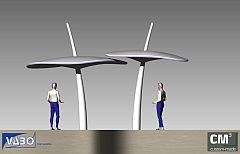

VABO Composites uses resin infusion (center) to build a wide range of composite products from ship doors (left) to architectural structures (right). SOURCE: VABO Composites.

VABO Composites (Emmeloord, Netherlands) was started by director Arnold Vaandrager in 2001, with several small marine projects. It proceeded to various applications for fishing vessels, including replacing metal storage boxes with composites. But the local fishing industry slowed significantly, forcing Vaandrager to look for new opportunities. “We have had to excel in what is difficult for others to make,” he notes. The company now completes a range of diverse projects, from industrial to marine to architecture, in a 3,000-m2 facility with a corps of 15 senior composites technicians and managers that scales up to 40 workers during large projects. Using mostly resin infusion, RTM Light and some wet layup, VABO has its own in-house design and materials & process engineers as well as fast tool fabrication using a CNC milling machine.

|

click square in lower right corner to enlarge video |

Composites enable this palletization machine to move more quickly, maintaining its tons/day productivity even though the number of bags to be stacked increased by 400%. SOURCE: VABO Composites.

The company has made composite antennas positioned on top of cars for on-location news crews, fiber-reinforced plastic (FRP) shovels for front-end loaders and lightweight manipulator doors/valves for a fast-moving palletizing machine. “This is the part of the machine that positions bags of potatoes or onions on a pallet,” explains Vaandrager. VABO replaced a 60-kg steel part with one made from composites weighing only 16kg. “The industry had changed from 10 kg bags to 2.5 kg bags,” he recalls, “so the machine had to speed up to maintain its current tons/day stacking rate, but it was too heavy to move that fast.” With composites, VABO was able to help the manufacturer maintain productivity, yet still provide strength and durability in the parts.

VABO Composites won a 2015 JEC Innovation Award for this composite front-loader bucket, which reduces weight up to 35% and enables greater volumes of materials to be moved vs. steel buckets. SOURCE: VABO Composites.

In 2015, VABO won the JEC Innovation Award in the Heavy Machinery category for its composite front-loader bucket, along with its Netherlands-based consortium partners Netherlands Aerospace Centre (NLR, Amsterdam / Marknesse), Institute for Composite Development (Instituut voor Composiet Ontwikkeling or ICO, Emmeloord) and construction equipment manufacturer Kuiken (Emmeloord), as well as materials supplier Gurit (Wattwil, Switzerland). ICO is located in the same building as VABO Composites and performs feasibility studies and engineering tasks for VABO.The original request to replace a steel front-loader bucket with a composite prototype came from Compoworld, an initiative of various stakeholders within the Netherlands composites industry, including the national government. With NLR as program leader, two different prototype buckets were produced: one at NLR in Marknesse, and the other at VABO Composites.

Testing in 2014 revealed that the composite buckets could move greater volumes of dirt and sand than was possible with a conventional steel bucket. Equipment users could therefore complete the same amount of work using fewer bucket loads. The up to 35% weight reduction could also lower fuel consumption and cost. The bucket is referred to as a "hybrid" because some parts, like the interface to the machine and the wear plate, remained in steel because switching these to composite did not add sufficient benefits. VABO began production of the hybrid bucket-loader in 2015.

Mastery in Marine Masts

VABO has also become a specialist in the design and construction of large radar masts for superyachts, like the 10m mast on a vessel launched earlier this year. Normally built from aluminum, VABO cut weight by 30% using composites. This is key, as the lighter weight up high lowers the vessel’s center of gravity, improving its stability. The FRP structure also saves on maintenance cost, eliminating the need for repainting due to its excellent corrosion resistance in a salt-water environment. VABO begins the multi-part assembly with pre-engineering, then proceeds through final engineering and design freeze, at which point it will begin CNC machining molds. All of the parts for this 10m mast were resin-infused using stitched glass fabrics and vinylester resin. The separate pieces were then adhesively bonded and mechanically fastened together. “We deliver a complete mast with the exhaust system integrated in the interior,” says Vaandrager, “so the builder has everything needed to install the integrated module.”

VABO makes resin infusion and large composite assemblies look easy as it builds this 10m tall superyacht mast complete with integrated exhaust system. SOURCE: VABO Composites.

VABO is now working on a 12m mast, made from infused carbon fiber and epoxy resin for increased weight savings. The project also includes the yacht’s canopy, or top deck, which will be produced as one piece. The multi-piece mast will be bonded using Gurit’s Spabond epoxy adhesives. The weight savings target for this mast will be 40-50% vs. aluminum. All of the mast’s engineering must be reviewed by Det Norske Veritas (DNV, Høvik, Norway), Lloyds Register (London, UK) or Bureau Veritas (BV, Neuilly-sur-Seine, France), depending on which classification society the yacht owner and builder have chosen for certification. “These masts typically take 6-7 months to complete after engineering is complete,” says Vaandrager. Fabrication for this latest project should be finished by the end of 2017.

Artistry in Architecture

VABO Composites has also become an expert in special projects for building and architecture end-uses. “We handle the whole project,” says Vaandrager, “starting from someone’s drawing on a piece of paper, to design and engineering, organizing the permits and 3D printing scale models so they can see and feel the parts.” Once the engineering is completed, VABO proceeds through molds, fabrication, assembly and installation.

|

|

|

|

|

VABO Composites used resin infused composites to realize CM3’s design for aesthetically-appealing canopies in the HUBS shelters from Emmen’s downtown parking to its city center zoo. SOURCE: VABO Composites, Codaworx.com and Rogier Bloemers Twitter feed.

VABO recently completed the HUBS series of nine visually attractive shelters from rain and sun along the boulevard between the parking plaza and zoo in the city center of Emmen, Netherlands. The organic-shaped canopies, built from infused glass fabrics, feature computer-controlled color-changing LED lights for nighttime appeal. “The challenge in this project was to maintain the canopy size and shape as the designer wanted,” Vaandrager recalls. “The canopy ‘leaves’ taper at the edges, which leaves restricted thickness for fitting the LED lights.” He notes that permitting on most projects is also difficult, because very few people in the building and infrastructure industry know about composites.

|

|

The Stratford Shoal sculpture uses thin composite shells clad with titanium to form its 73 leaves. SOURCE: VABO Composites. (For more info, see DeZeen magazine's article.)

The success of HUBS follows earlier architectural projects like five 9m x 3m suspended shells for a jewelry exhibition at the Louvre and 73 titanium-clad FRP leaves for “The Stratford Shoal”, a 250m titanium sculpture at the Stratford Centre in London. Developed to camouflage an aging shopping center and car park, the sculpture was installed prior to the 2012 Olympics. The leaves were manufactured from a thin FRP shell over a plywood structural frame, made from three molds to give three varying forms. VABO used a vacuum infusion molding process. The leaves were finished with titanium sheets, anodized to display as shades of green, yellow and silver.

High Fit and Finish in Commercial Production

Now VABO is pursuing commercial production of its Accedoo composite ship doors and hatches. (See CW’s APPLICATION story “Full steam ahead for composite ship doors and hatches”.) VABO uses an insert in the infusion mold for the hinge so that it is covered with gel-coated composites for both aesthetics and durability. The parts also come out of the aluminum molds completely finished.

|

|

|

SOURCE: VABO Composites

Due to its new developments in certified composite ship doors and hatches, and also in the composite bucket loader, for which it won the 2015 JEC Innovation Award along with its partners, VABO Composites was voted as the winner of the Flevo Innovation Medal 2016.

See more videos from VABO at https://www.youtube.com/user/vabocomposites

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Full steam ahead for composite ship doors and hatches

VABO Composites (Emmeloord, The Netherlands) has added to its wide range of composite products these ship doors and hatches that offer a 50% weight reduction vs. conventional steel doors.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More