Very Light Cars: Driving the future

X Prize-winning technology aims to change vehicle architecture.

Engineering Challenge:

Using conventional materials, build a safe, cost-effective, mass-producible car capable of a 200-mile/322-km range and a 100-mpge (42.5 km/le) combined highway/city driving cycle.

Design Solution:

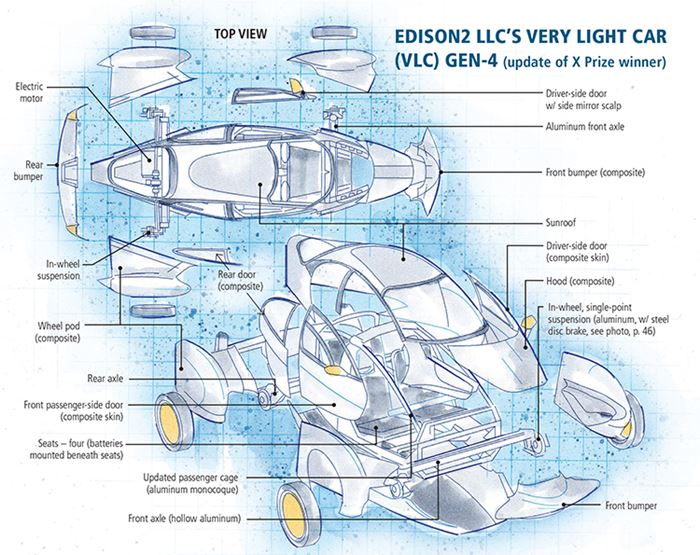

Develop a unique multimaterial vehicle that comprises an aluminum in-wheel/single-connection-point suspension system, a chrome-moly alloy chassis and composite body panels that reduce mass and complexity.

When Edison2 LLC (Lynchburg, Va.) entered the Progressive Insurance Automotive X Prize competition five years ago, it and 42 competitors faced a daunting task: design and build a production-capable, affordable and safe passenger vehicle with a driving range of 200 miles/322 km per tank of fuel or electric charge and at least 100 mpg (42.5 km/l) or equivalent efficiency. (Read more about the Automotive X Prize challenge, its rules, and the results at http://www.progressiveautoxprize.org.)

Determined to win, Edison2 entered four vehicles — two in the competition’s mainstream four-passenger category and one each in two “alternative” categories. Notably, each of the four vehicles was powered not by an electric power plant, but by a turbocharged, exhaust-gas recirculating (EGR) internal combustion engine (ICE) that burns E85/ethanol fuel. Although the alternative vehicles were sidelined (one by mechanical problems), the other two were the $5 million winner and first runner-up in the mainstream category. The winning vehicle delivered 110 mpge (46.8 km/le) despite the fact that its engine was choked back to comply with the competition’s tight emissions standard. The Edison2 team believes its prizewinner is no mere novelty. In the three years since the award the company has refined its Very Light Car (VLC), betting that its unique take on the passenger vehicle sets the course for automotive technology.

Maximizing mass reduction

“We left no stone unturned in trying to make these cars as light as possible while also building the best case that our design could meet relevant safety standards to protect occupants,” says Brad Jaeger, Edison2’s VP, engineering and operations. To meet the X Prize’s efficiency and emissions requirements, the team knew it would need to design a completely new vehicle architecture — no technology currently on the road came close. But to ensure the work would have meaning beyond the competition, the team felt it was necessary to execute the design in conventional materials, using existing construction techniques so that production cars based on the new architecture could be built at low cost. “Everybody and his brother makes things that are exotic and crazy,” notes Oliver Kuttner, Edison2’s cofounder and CEO, “but we felt if you couldn’t make these cars at a low price, then the whole exercise would mean nothing.”

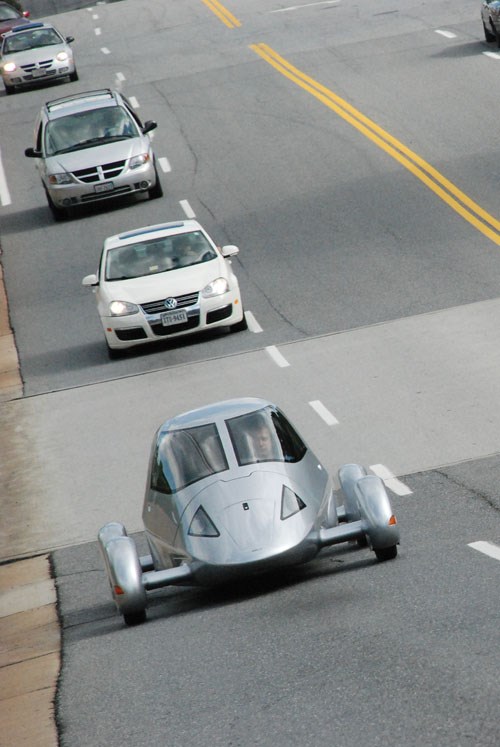

One of the first things you notice about VLCs is their low, wide stance with their wheels pulled out from under the body like a Formula 1 race car. This profile is possible because the patented suspension system — including springs, dampers and universal joint — actually resides inside the hub on which each wheel is mounted, rather than on the axles as in conventional cars. Rather than the typical three-point connection of a MacPherson strut, the wheel’s vertical movement/rotation and braking are all transmitted through a very robust single fixed-connection point on each wheel. That one innovation permitted simplification of the whole vehicle structure and, thanks to mass-decompounding effects, significantly reduced the curb and unsprung weight. Each in-wheel suspension unit, which is machined from aluminum (only the disc brakes are steel), weighs only 12 lb/5.5 kg. According to Jaeger, the patented “suspension system leads to a greatly simplified vehicle structure, which in turn gives auto designers unparalleled freedom to think in quite different ways about how the rest of the car goes together.”

“Since strut towers are eliminated,” Kuttner illustrates, “it becomes possible to make flat floors, which opens up the central area of the car, creating energy-absorbing space that improves safety and is well-suited to composites, while providing aerodynamic benefits.” But he notes that each innovation brings new challenges. “You can’t put a normal seat in the car because the track is in the wrong place,” he says, and adds that “you have the opportunity to create a different kind of seat that behaves differently in a crash.” The automaker and supply-chain members that capitalize on such opportunities, he maintains, will ultimately prevail when VLCs become a recognized and viable vehicle segment.

As they evolved, the X Prize vehicles were structurally “minimalist” designs, which Kuttner describes as “cars with the complexity of motorcycles [that] probably have fewer parts than any car in history, and so [they] cost less money to make.” To ensure as light a vehicle as possible, the team decoupled the body’s exterior skin from its primary structure. That is, the body panels weren’t expected to contribute significantly to energy management in a crash. This broadened the team’s potential range of lightweight materials, particularly plastics and composites. “We like plastics because we can reduce part count, molding them in ways that consolidate components,” notes Kuttner. “And using fewer parts, making the vehicles less complicated, creates price reductions.” Because most team members have racing backgrounds, they are familiar with composites in general and carbon fiber-reinforced plastics (CFRP) in particular. Although an early iteration of the VLC was hand built using glass-reinforced unsaturated polyester, CFRP was used in the X Prize vehicles to make them as light and safe as possible.

The X Prize winner’s primary structure is a tubular frame of chrome-moly (a steel alloy containing both chromium and molybdenum) that weighs only 57 lb/26 kg. (Chrome-moly offered a better strength-to-weight ratio than conventional steel, enabling Edison2 to form tubes of sufficient strength but with thinner walls and smaller diameters to minimize frame weight)

To meet the competition’s tight timeline, Edison2 outsourced tool and body-panel production to a trusted supplier, Wolfden Products Inc. (Columbus, Ohio). Wolfden designed the break lines in the body’s surface for the roof, hood and door panels and hand laid the tools for the components in composites (sufficient for few-of-a-kind production). The final body shell weighed about 38 lb/17 kg, and the aerodynamic canards/pods around the wheels weighed ~6 lb/~2.7 kg each. The components were vacuum-bagged, autoclave-cured carbon fiber/epoxy. The typical layup was two plies of 3K tow/2x2 twill-weave carbon fiber fabric from BGF Industries Inc. (Greensboro, N.C.) on the face side and back side of a Nomex honeycomb core from Plascore Inc. (Zeeland, Mich.). Unidirectional carbon fiber prepreg from APCM LLC (Plainfield, Conn.) and woven Kevlar prepreg were selectively used to add strength.

The lightest of the Edison2 X Prize cars was 710 lb/322 kg curb weight, and the heaviest was 765 lb/347 kg, yet both were roomy enough to seat the 6-ft, 4-inch (1.93m) tall Kuttner. “No one’s ever built a car that weighs 750 lb [and] seats four people like me,” he notes. “I can sit in the back seat.” A Virginia-based real estate developer and longtime participant on teams that design and build two-seat sports cars and sports prototypes, Kuttner points out that the team’s past work on race cars definitely paid off: “Good race cars are efficient. That’s how you win races. You have to build everything so it’s balanced for a given size and power. The X Prize competition was just a different set of parameters.”

Aerodynamic composites

Just as important as low mass was reduced drag. Here, a key contributor was Barnaby Wainfan, an aerodynamics fellow at Northrop Grumman Corp. (Falls Church, Va.) and an adjunct professor of aeronautical engineering at the University of Michigan (Ann Arbor, Mich.). Wainfan and Ron Mathis, Edison2’s chief of design, had collaborated on auto racing projects, so when it was time to design the external surface of the X Prize vehicles, Mathis asked Wainfan to come aboard. Although the team made a few changes (e.g., adding lights and door latches), the surface Wainfan developed is essentially that used on the X Prize cars, and the team credits him with a big contribution to the breakthrough fuel efficiency of its VLCs.

Notably, the team performed no computational fluid dynamics (CFD) analyses or wind tunnel testing during the initial vehicle design, but after the design was “locked” by the X Prize judges, the team was invited to test its car for one shift at the General Motors Co. (GM, Detroit, Mich.) wind tunnel in Warren, Mich. GM technicians noted that the vehicle exhibited the lowest drag they had ever measured on a multipassenger vehicle: a coefficient of drag (Cd) of 0.160 with a frontal area of 1.706m2/18.36 ft2. “Clearly, our Cd rating was critical in achieving the X Prize target of 100 mpge,” says Jaeger.

Although the team made good use of CAD software (SolidEdge from Siemens PLM Software Inc., Plano, Texas), for the most part “the X Prize vehicles were designed with a lot of real-world experience by a few incredible engineers who took a lifetime of learning and used it to make best guesses moving forward,” explains Jaeger. “Since we weren’t trying to design a door handle that would last 100,000 miles, most of the engineering work was based on simple calculations and experience.” For its “gen-4” VLC (the X Prize vehicles were “gen-3”), the team is working with Altair Engineering Inc. (Troy, Mich.) to refine its design and ensure the next working prototype will be as compliant as possible with U.S. occupant safety laws.

A key design challenge was passenger ingress and egress. Conventional doors would open straight out and strike the wheel pods, but gull wing doors are notoriously challenging from both design and operational perspectives. Further, the vehicles had very high doorsills to ensure passenger cell crash integrity. Edison2 compromised with a hybrid “butterfly” door that initially pivots forward (to clear the wheel pods) and then up toward the roof. This gave designers the shut-face/sealing surface they needed and spread the load across the car’s width so they didn’t need an oversized (and heavy) U-joint to open the doors. Although it worked well for the competition, Jaeger — a pro race car driver and the pilot of Edison2’s X Prize vehicles during the competition — says they will go in a different direction with gen-4 doors.

Given the extremely light primary structure and body panels, Edison2 was able to use a highly modified version of the WR-250 engine with which Yamaha Motor Co. (Iwata, Shizuoka, Japan) powers its motorcycles. It achieves a 29-hp rating for Yamaha, but coupled with a BorgWarner Inc. (Auburn Hills, Mich.) variable-vane turbocharger and an extensive EGR system designed by Edison2 (and despite the choking required for emission compliance), it cranked out 40 hp — power aplenty for the X Prize cars.

As it sought simplicity, however, Edison2 did not sacrifice drivability. Superior handling, in fact, was a secret weapon in the team’s arsenal, because members knew that in the final round of the X Prize competition there would be a race. Cornering capability could mean the difference between winning and losing the purse. “Because it’s so low mass,” says Kuttner, “it handles exquisitely. It out-handles just about anything you can buy. I think once you get used to it, you don’t want to go back to a heavy car.”

Another benefit that the unique suspension system provides is large crush zones between each wheel and the vehicle body to absorb energy during accidents — a critical feature for occupant safety on such light cars. Notes Kuttner, “The biggest technical challenge is how to make such low-mass cars safe. The main reason the wheels stick out is because they become crush zones. When you build a low-mass car like this, you have to create more space to absorb an impact.” Indeed, not only is the chassis of the VLC designed for better force management for improved safety and more efficient use of space, but the suspension design reduces rolling resistance on tires, making the vehicle easier to steer and improving the ride. The VLC did very well in the challenging Insurance Institute for Highway Safety (IIHS, Arlington, Va.) 40-percent-offset barrier impact trial.

Back to the future

Since picking up an X Prize, the Edison2 team has been hard at work proving its win wasn’t a fluke. Its early fiberglass-bodied vehicle has been repurposed twice, once as a battery-electric vehicle (BEV). When Kuttner drove the BEV across the U.S. in October 2012, it attained 350 mpge (149 km/le) — twice the fuel efficiency achieved by Edison2’s EV competitors for the X Prize and far better than any BEV currently on the road. “When we started,” he says, “I really didn’t like electric cars, but I don’t discount them anymore. I can drive 100 miles for $1.12 — that’s a stunning number.”

The team is looking for a mainstream automaker that is interested in licensing the know-how, but is also busy converting the BEV to an extended-range hybrid EV, which is about a year away from a production-capable prototype. The company also coupled a smart car drivetrain with its unique body architecture and got 89 mpge (38 km/le) — more than twice what Daimler AG gets on the smart car. But, Kuttner contends, “what engine goes into the car is irrelevant at the end because it’s the architecture that makes the real difference. Our approach is all about developing cars that are both inexpensive to make and inexpensive to sell, because an industry with no profit margin left — that’s death!” Kuttner should know. He has previously owned several car dealerships. And he promises that some variant of his VLC will be available for consumer purchase by 2016.

Related Content

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)