CW Blog

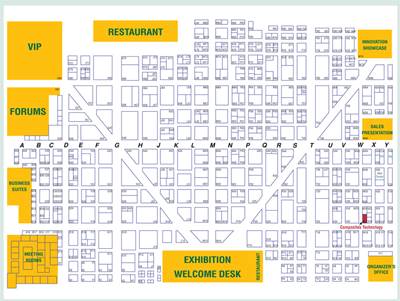

JEC Composites 2009/SAMPE Europe preview

Organizers predict good turnout in poor economy for annual Paris tradeshow.

Read MoreInfrastructure rallying cry

One of the buzz phrases surrounding President Obama's stimulus legislation is “infrastructure construction.” Composites professionals know that if we want a lasting solution to current civil infrastructure needs, 21st Century materials and technology must be used. We know that composites offer that option. But they — government officals, civil engineers and other decision-makers — don’t know.Who will tell them, if not us?

Read MoreIs it really low-tech vs. high tech?

I’ll bet that a lot of folks who read this column regularly — assuming I’m lucky and lots of folks are reading — have spent their entire careers working with E-glass without ever thinking they were high-performance geeks, too. To them, welcome to the club!

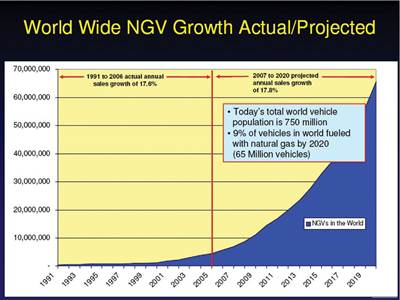

Read MoreThe outlook for composite pressure vessels

Environmental and economic pressures continue to drive growth in the market for composite pressure vessels used in personal and public transportation applications.

Read MoreNAIA 2009 show highlights

The Detroit auto exhibition’s hybrid and electric vehicle introductions underscore the need for lightweighting with low investment cost, which composites can provide.

Read MoreComposites ride and support the rails

Increased ridership and heavier axle loads on rail systems around the world signal a potential boon for composites.

Read MoreMechanical wedge grips for tensile testing

In tensile testing, wedge grips are used on both ends of the specimen to position the specimen in the test frame.

Read MoreFinite element analysis garners performance gains for yacht component

In the ongoing quest to reduce weight in high-performance sailing yachts, no part goes unexamined or untouched.

Read MoreDielectric heating speeds honeycomb core manufacture

Many composites, particularly those made with glass or aramid fibers in a polymer matrix, tend to be inherently nonconductive.

Read More"Metalworking" businesses find new niche with composites

Composite structures are replacing machined metal parts in certain applications — most notably, some aircraft components. As this happens, it would be easy to assume that businesses invested in machining metal will see activity decline. From the ground, however, there is plenty of evidence to support a different assumption.

Read MoreAircraft delays alter carbon fiber supply/demand balance

When Boeing announced in early December that it was officially pushing back the first flight and the first delivery of the 787 Dreamliner to second quarter 2009 and first quarter 2010, respectively, one of the first questions that circulated among our staff centered on the issue of carbon fiber supply.

Read MoreBeyond the Concorde: Next-generation SSTs

Civilian supersonic flight could begin a new era as aircraft developers position composites-intensive designs for market entry, particularly in the business-jet niche.

Read More