CW Blog

Integrated drop-in-place superstructure the solution for Eight Mile Bridge

Based on the successful performance of previous composite bridge decks installed in Hamilton County, Ohio, highway engineers recently took a bold step, specifying an integrated composite bridge superstructure — that is, deck and support beams together in one unit — to replace a deficient span known as Eight Mile Bridge.

Read MoreNew tooling paste enables complex pattern manufacture

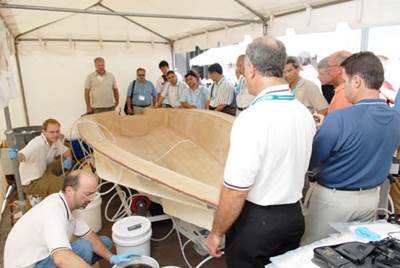

Seaway Group (Begunje, Slovenia) is a well-known boat development company created in the early 1980s by Jernej and Japec Jakopin. Not only does the company design award-winning craft, like the Skagen 50 motor yacht, but it also performs contract engineering and produces tools and patterns to print.

Read MoreCOMPOSITES & POLYCON 2009 preview

The ACMA’s annual tradeshow takes its first turn in its new January timeframe.

Read MoreIBEX 2008 postshow review

Despite a sluggish boatbuilding market, this annual Miami marine showcase was the platform for the introduction of innovative composite products.

Read MoreBitter pill for the Big Three

It appears that the U.S. auto industry, or at least the automakers known as the Big Three — GM, Ford, Chrysler — is in the midst of choosing which bitter pill to swallow.

Read MoreWatching a half-century of progress in composites

Looking back on my experience in the composites industry, from my first job in 1961 as a free-lance secretary to Brandt Goldsworthy to my last job as a free-lance writer for Composites Technology and High Performance Composites, gives me an uncommon perspective.

Read MoreWhat's new in automotive front-end modules?

Composite and hybrid composite/metal solutions reduce cost and weight and increase assembly efficiency on passenger vehicles.

Read MoreUnmanned rotorcraft passes stringent German Navy shipboard tests

CAMCOPTER’s high strength-to-weight ratio is made possible by composite materials.

Read MoreMOM software solves debonding problem in manufacturing process

When Composites Atlantic Ltd. (CAL, Lunenburg, Nova Scotia, Canada) contracted to produce 10 types of parts for leading edge and rudder components and deliver them on a biweekly schedule to a key aerospace customer, trouble soon cropped up.

Read MoreWind Blade Manufacturing: Cost-efficient materials-based strategies

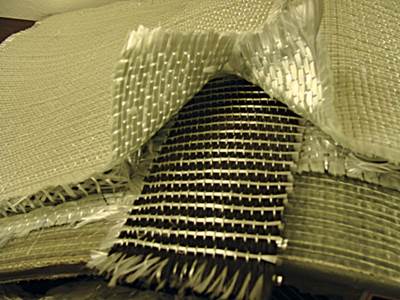

The wind blade’s four key elements — the root, the spar, the aerodynamic shell or fairing, and the surfacing system — have present unique manufacturing challenges that must be met with carefully selected composite material systems and molding strategies.

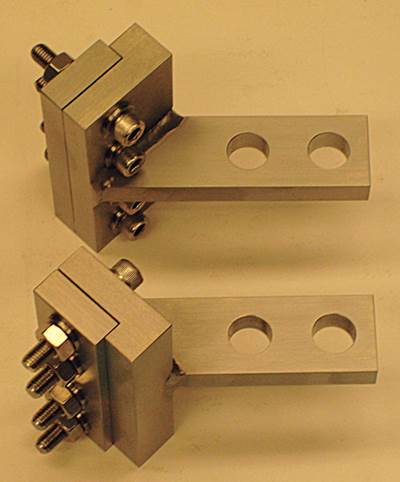

Read MoreThrough-the-thickenss tensile strength testing using a curved beam

The in-plane strength properties of a composite material, axial and transverse tension and compression and in-plane shear, are usually the first to be considered in design. However, through-the-thickness (interlaminar) strength properties cannot be ignored. Through-the-thickness tensile strength, in particular, can be critical to structural performance.

Read MoreComposites encourage design creativity in LSA aircraft

Manufacturers of small aircraft expand the private pilot’s options on the strength (-to-weight) and contourability of advanced composites.

Read More