CW Blog

Vestas implements composites 3D printing to increase efficiency for blade alignment tools

A Markforged digital repository and multi-material 3D printers enable faster, more accurate and less costly manufacture of a variety of tools and blade components across Vestas sites.

WatchComposites industry continues early 2022 trends into June

As in May, a majority of the components in the Gardner Business Index (GBI): Composites Fabricating continue movement into slowed expansionary growth.

Read MoreOverair's Butterfly eVTOL prototype to integrate composites-intensive design

Aiming for first flight tests in the latter half of 2023, Overair’s Butterfly aircraft uses Toray carbon fiber/epoxy prepreg strategically to cut weight on its battery-powered, quiet aircraft.

WatchHigh-performance, high-detail continuous 3D-printed carbon fiber parts

Since 2014, Mantis Composites has built its customer and R&D capabilities specifically toward design, printing and postprocessing of highly engineered aerospace and defense parts.

Read MoreSustainability has come to composites and it's here to stay

It might be tempting to think of sustainability as a buzzword, but there are structural changes taking place in the composites industry that signal its permanence.

Read MorePlant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

Read MoreFostering best practices for wet layup procedures

As fabricators continue to manufacture composite tools and parts using an open mold, wet layup process — often with mixed success — it’s important to stress proper preparation, materials, application methods and standardization.

Read MoreComposite buildings go monocoque

Superior protection from the elements plus fast, affordable installation and maintenance have quickly made Orenco Composites’ DuraFiber buildings an attractive choice for water and wastewater, communications, transportation and power industry outbuildings.

Read MoreImpressions and takeaways from JEC World 2022

Suffice to say that JEC World 2022, the “Big Show” for the composites industry, exceeded many expectations. Dale Brosius contemplates pervasive themes, conversations and takeaways from the international event.

Read MoreTop 10 Considerations When Buying a CNC Machine for Composites

For a CNC machine to continue to meet or exceed a company’s needs, it must be built and spec’d with these needs in mind.

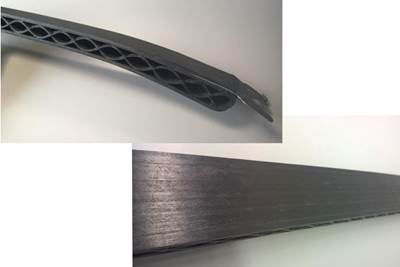

Read More3D printing and AFP join forces in automotive demonstrator

Bavarian auto industry and TU Munich research how to reduce molding costs by combining continuous fiber and 3D-printed composites.

WatchCompositesWorld JEC World 2022 recap: CompPair demonstration

Switzerland-based CompPair illustrates how heat triggers the self-healing properties of its recyclable composite materials, repairing a panel in about one minute.

Watch