CW Blog

Demonstrating composite LH2 tanks for commercial aircraft

Toray Advanced Composites and NLR discuss the Netherlands consortium and its 4-year project to build demonstrator liquid hydrogen tanks, focusing on thermoset and thermoplastic composites.

Read MoreCFRTP upper stage propellant tank

PROCOMP uses in-situ consolidation AFP and ultrasonic welding to demonstrate lightweight, novel tank design.

Read MoreComposite Engineering Challenge

The Growth Garage Business Incubator of the Mitsubishi Chemical Group Advanced Materials Division is hosting the Composite Engineering Challenge to support next generation startups scale up production of lightweight parts.

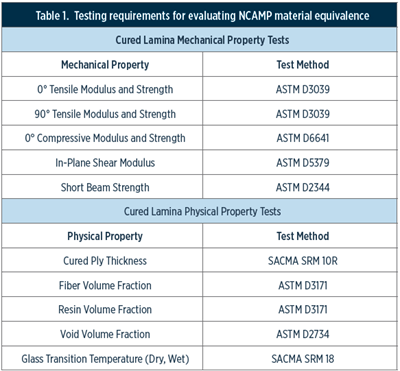

Read MoreMaterial equivalence testing in shared composites databases

In response to traditionally proprietary polymer matrix composites (PMC) qualifications, NCAMP continues its efforts to make material property databases publicly available.

Read MoreDownload today's CAMX 2022 Show Daily: Thursday, Oct. 20

Download today’s news reported live by CW on the CAMX show floor in Anaheim, California. Headlines cover the Good Day, CAMX panel, more information about ACE Award winners and the various technologies transforming the show floor.

Read MoreDownload CAMX 2022 Show Daily: Wednesday, Oct. 19

Download news reported live by CW on the CAMX show floor in Anaheim, California. Headlines cover CAMX/ACE Award winners, educational enrichment offered by the CAMX Theater, reconnection and recharging opportunities at CAMX Park Place and more.

Read MoreDrawing design cues from nature: Designing for biomimetic composites, Part 1

Biomimicry is an interdisciplinary methodology that can inform composites design and manufacturing via use of more effective and sustainable materials, structural fabrication and technological practices.

Read MoreDownload today's CAMX 2022 Show Daily: Tuesday, Oct. 18

Download today’s news reported live by CW on the CAMX show floor in Anaheim, California. Headlines cover this morning’s keynote, Michael Steep, Good Day, CAMX, ACE/CAMX award finalists and more.

Read MoreKite-based energy system aims for high-output, low-impact wind energy

Netherlands-based startup Kitepower’s Falcon airborne wind energy (AWE) system deploys a fiberglass-intensive kite to generate wind energy with a low ground footprint.

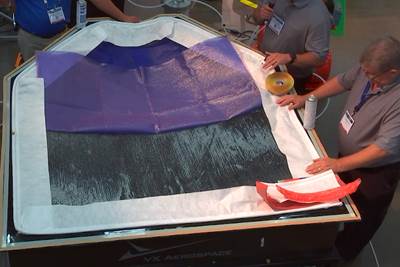

Read MoreDigital Demo: Aerospace Carbon Fiber Infusion

Learn how this process combined with carbon fiber can offer the manufacturer the benefits of increased strength and the ability to make a lighter-weight part.

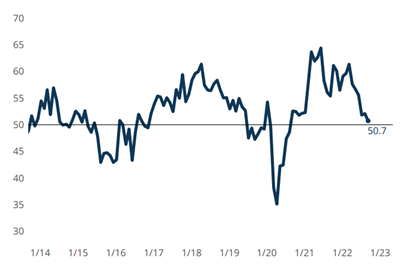

WatchGBI: Composites Fabricating approaches contraction in September

The GBI: Composites Fabricating closed September on the verge of “flat,” a reading the Index has not seen in two years.

Read MorePlant tour: AvCarb, Lowell, Mass., U.S.

Composites are often selected for their structural properties, but at AvCarb, innovation in carbon fiber-based products has driven fuel cell technology advances for decades.

Read More