CW Blog

CompositesWorld JEC World 2022 recap: GKN Aerospace demonstration

Arnt Offringa, director of the Global Technology Center Netherlands at GKN Aerospace, explains to CW the processes and materials used in a frame assembly for Clean Sky 2’s Multifunctional Fuselage Demonstrator (MFFD).

WatchAugmenting engineered thermoplastics with natural fibers

The Paris Climate Accord mandate for net-zero carbon by 2050 has kick-started an innovation revolution for natural fibers and sustainably engineered resins.

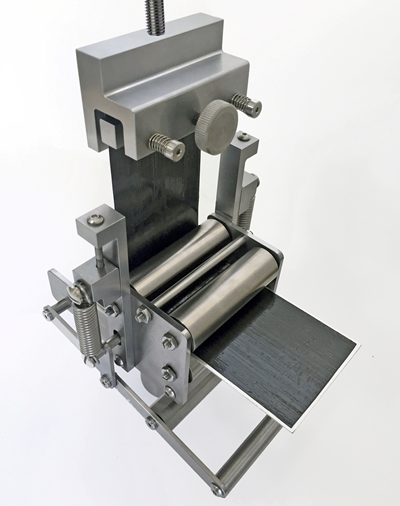

Read MoreComposite prepreg tack testing

A recently standardized prepreg tack test method has been developed for use in material selection, quality control and adjusting cure process parameters for automated layup processes.

Read MoreData visibility increases efficiency, competitiveness for composite infrastructure solutions company

ClockSpring|NRI builds composite strengthening systems for pipes and civil structures, using Global Shop Solutions ERP software to help track and manage cost and production data.

Read MoreComposites industry continues slowing expansion trend

The composites GBI “plays it again” in May at 56.7, mostly following the trend of slowing component expansion, though employment is an exception.

Read MoreJEC World 2022, Part 3: Emphasizing emerging markets, thermoplastics and carbon fiber

CW editor-in-chief Jeff Sloan identifies companies exhibiting at JEC World 2022 that are advancing both materials and technologies for the growing AAM, hydrogen, automotive and sustainability markets.

WatchJEC World 2022, Part 2: Recycling, natural fibers and additive manufacturing

CW associate editor Hannah Mason recaps several technologies seen on display at JEC World 2022, including new developments from Bcomp, Massivit 3D, Gen 2 Carbon and more.

Read MoreJEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

WatchWhat to make of the first JEC World in three years

CW went to JEC World 2022 not sure what to expect. We were pleasantly surprised, and learned much about where and how new composites technologies are being developed.

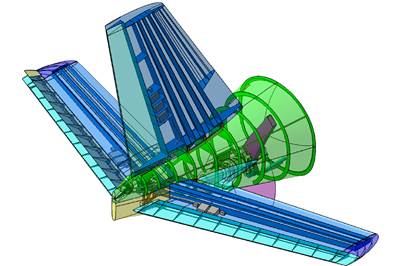

Read MoreMulti-flange RTM frames enable radical rear fuselage design

The Clean Sky 2 Advanced Rear End (ARE) demonstrator combines patented new frame design, thermoset and thermoplastic composites and smart tooling to advance aircraft design and cut weight, cost and production time.

WatchDigital design, multi-material structures enable a quieter supersonic NASA X-plane

NASA’s composites-intensive X-59 QueSST experimental aircraft is set for its first flight by the end of 2022, after nine years of design, manufacture, assembly and testing by Lockheed Martin Skunk Works.

WatchMoving toward next-generation wind blade recycling

Suppliers, fabricators and OEMs across the composite wind blade supply chain ramp up existing technologies, develop better reclamation methods and design more recyclable wind blades.

Read More