CW Blog

Multi-material steel/composite leaf spring targets lightweight, high-volume applications

Rassini International was challenged by Ford Motor Co. to take weight out of the F-150 pickup truck. Rassini responded with a multi-material steel/composite hybrid leaf spring system that can be manufactured at high volumes.

Read MoreCW Tech Days: Design, Simulation and Testing Technologies for Next-Gen Composite Structures

Designed to provide a multi-perspective view of the state of the art in design, simulation, failure analysis, digital twins, virtual testing and virtual inspection, this one-day online event will feature presentations from design and materials experts representing a range of composites industry stakeholders including academia, CAD and CAE software suppliers, laboratories, and fabricators.

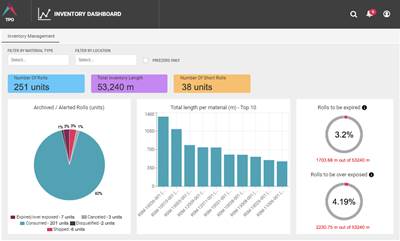

Read MoreComposites supply chain and production disruptions – how can AI and digitalization help?

Digitizing and creating the factory of the future is a journey, but it has the potential to help composites manufacturers address real-life disruptions and enable fast replanning of production operations for increased flexibility and enterprise-level performance.

Read MoreRefurbishing bridges at half the time, cost versus replacement

Instead of demolishing and rebuilding bridges, SUREbridge doubles the strength and durability of existing structures with an FRP deck for a smart, sustainable solution.

Read MoreCycling forward with bike frame materials and processes

Fine-tuning of conventional materials and processes characterizes today’s CFRP bicycle frame manufacturing, whether in the large factories of Asia or at reshored facilities in North America and Europe. Thermoplastic resins and automated processes are on the horizon, though likely years away from high-volume production levels.

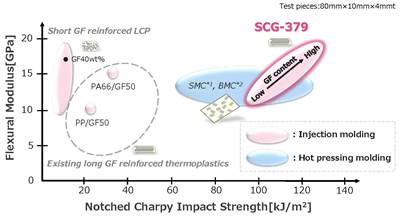

Read MoreLong-fiber liquid crystal polymers

High-performance, injection moldable grades to be offered with long glass, carbon fiber options.

Read MoreFrom sailplanes to composites repair: Growing composite training opportunities over the years

Mike Hoke discovered his interest in the composites industry at a young age. His journey eventually led him to Abaris Training Resources, which he owned and evolved for more than 30 years.

Read MoreComposite rotary milking platform evolves via process innovations

Infusion and LRTM-based processes and design enabled Waikato Milking Systems to bring a lighter, less labor-intensive platform to the global dairy market.

WatchAthletic shoe developed with repurposed thermoplastic waste

Manufactured via a single-step molding process, Decathlon’s Traxium Compressor soccer cleats propel the sporting goods market toward more recyclable solutions.

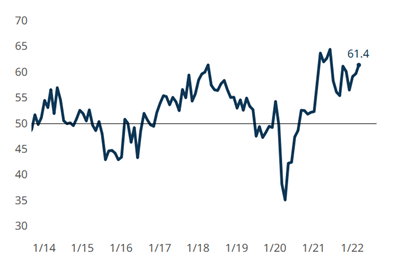

WatchComposites industry continues 2022 upswing

The Gardner Business Index closed March out at 61.4, with production activity continuing to persist despite some restraints caused by supplier delivery and employment components.

Read MorePrecision pyrolysis: Controlled, heat-based composites recycling for higher material properties

Japan-based Fuji Design’s recycling technology involves controlled, cyclical heating and cooling for higher-performance fiber reclamation. New partnership with Teijin Ltd. aims to scale up and commercialize the technology.

Read MoreAutomated, continuous processes for high-volume automotive and defense components

Thunder Composite Technologies uses its automated pultrusion, RTM and other processes to produce custom-engineered composite parts for automotive and land defense vehicles.

Read More