CW Blog

Graphene nanotubes enhance conductivity, performance of composite printing sleeves

Two customer projects demonstrate that small amounts of OCSiAl's TUBALL nanotubes can replace carbon black for fiberglass composite printing sleeves.

Read MoreHigh-performance sustainability and cost-efficiency advance with HiPerDiF

In the latest chapter of the HiPerDiF (High Performance Discontinuous Fibre) story, commercial production is on the near horizon for high-performance composite materials that are both sustainable and formable, leading to simpler, more cost-efficient composites manufacturing.

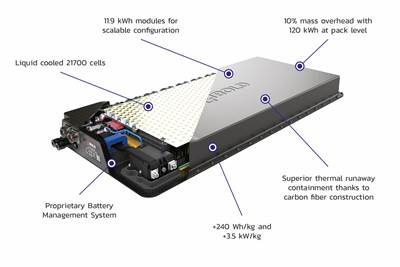

Read MoreTroubleshooting thermal design of composite battery enclosures

Materials, electrical insulation and certification are all important factors to consider when optimizing electric battery performance against potential thermal runaway.

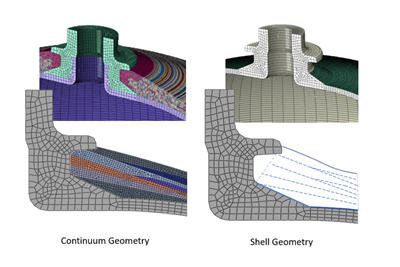

Read MoreImproving analyses of composite pressure vessels

Accurate geometry modeling and equivalent material property approximations captured by WoundSim will play a role in improving COPV analyses.

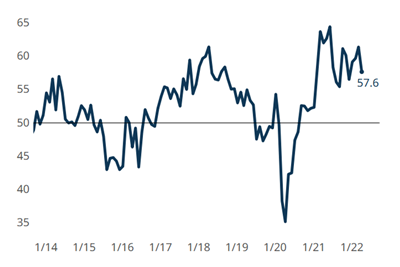

Read MoreComposites Index experiences fluctuating expansion

The GBI: Composites Fabricating continues to shift between accelerated and slowed expansion in short periods of time, but not enough to anticipate risk of contraction.

Read MoreAdditive for Composites and Composites for Additive

CompositesWorld’s Jeff Sloan joins Peter Zelinski in an episode of the AM Radio podcast about how composites and 3D printing are changing one another.

ListenDifficult Materials Make Automated Fabric Cutting More Indispensable than Ever

With lingering supply chain shortages, difficult-to-cut materials like Kevlar and many others demand a more accurate and efficient cutting process. Automated cutting is the answer.

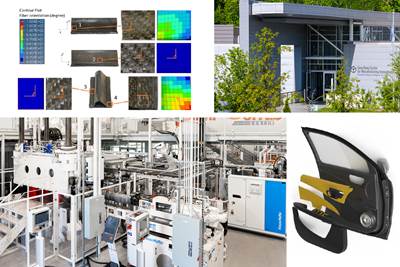

WatchClemson Composites Center: Working with industry to transform composites

Offering liquid and thermoplastic composites molding, LCA-weighted simulation, full testing to validate materials/process data cards, CCC’s digital life cycle approach unites manufacturing, microstructure, part property map and structural analysis.

Read MoreMust-have capabilities in a large-format additive manufacturing machine

Thermwood’s Large-Scale Additive Manufacturing (LSAM) system comes equipped with many features that make fabrication of large fiber-reinforced polymer parts and structures fast, efficient and accurate.

WatchKVE INDUCT: Welding a torsion box demonstrator

To meet sustainability targets and market demands, the aerospace industry is searching for alternative joining methods. Automated assembly of thermoplastic composite structures by induction welding offers a solution. (Sponsored)

WatchCompositesWorld is on the road again

Since CW’s infancy, its editors have strived to imbue its coverage with a sense of place, whether that’s through plant tours, facility visits or trade shows. After a pandemic, this has never seemed more important.

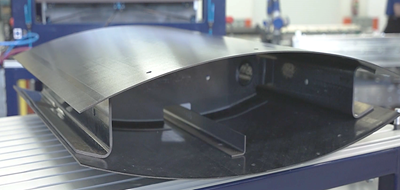

Read MoreSuCoHS project: Advancing composite solutions for parts with high thermal and mechanical loads

New materials, structural concepts and manufacturing using sensors for composites that resist fire, temperature and loads while providing weight and cost savings versus metals.

Watch