CW Blog

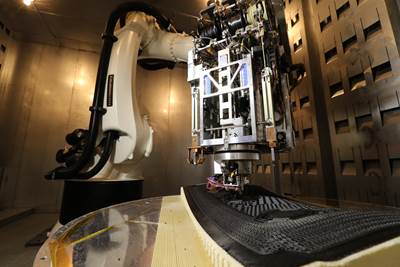

Combining AFP with 3D printing for flexible parts production

Electroimpact creates a multifunctional manufacturing cell for complex, aero-quality continuous fiber composite parts.

WatchMold cleaners, primers, sealers and internal/external releases

AXEL Plastics reviews its line of mold cleaners, primers, sealers and internal and external mold releases designed for closed mold and pultrusion manufacturing processes.

WatchHow Digital Cutting Technology Reduces Costs and Improves Flexibility

Automated cutting of composites reinforcement and other technical textiles is faster, more accurate and can result in dramatic reductions in material waste and labor. Having the right software is the key to getting the best results.

WatchGraphene 101: Forms, properties and applications

Graphene-enhanced composites find new applications across end markets as the supply chain continues to mature.

Read MoreBuilding the Museum of the Future

FR composite panels provide structure, sealing and iconic facade for pioneering architecture in Dubai.

Read MorePhysical testing to characterize composites

Shimadzu Scientific Instruments reviews use of static tests, impact tests, internal observations and fracture observations to assess and characterize the physical properties of composite parts and structures.

WatchVitrimers: The reprocessable thermoset

Vitrimers are not classic thermosets and they are not classic thermoplastics, but they behave like both and as such offer the best of both worlds. CW catches up with Mallinda for an explanation.

WatchValuable data: From travelers to the as-built digital twin

Taking advantage of the electronic record proves to be of significant value to composite fabricator’s record-keeping process.

Read MoreComposites Academy launches online training with hands-on exercises

Composites Expert and Institut de Soudure partner to provide interactive advanced composites training to students and professionals worldwide.

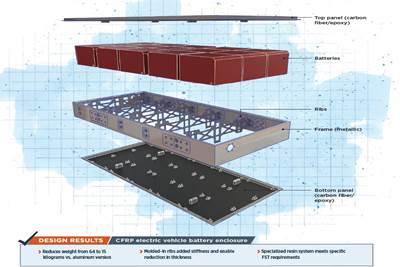

WatchEV battery enclosure inspires material, process innovations

High unit volume and low weight requirements for electric bus battery enclosures fueled development of TRB Lightweight Structures’ specialized epoxy system and automated composites production line.

Read MoreDevelopment of ASTM standards for composites: An insider’s perspective

According to Dan Adams’ inside perspective, two elements determine whether a proposed test method for composite materials becomes an ASTM standard.

Read More