CW Blog

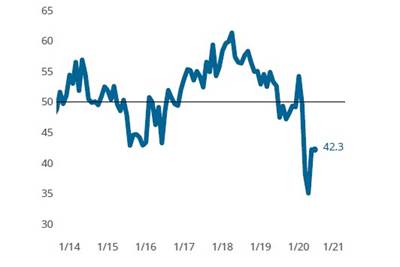

Composites Index reading remains unchanged from May

June’s readings remain the same as quickening supplier deliveries offset improvement in new orders and production.

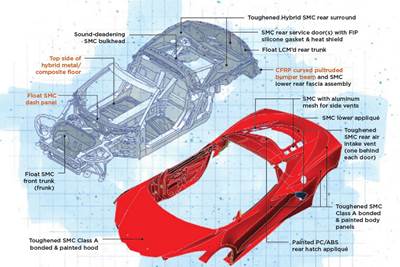

Read MoreComposites-intensive masterwork: 2020 Corvette, Part 2

Innovative composite materials trim mass, costs and noise on the high-volume mid-engine sports car.

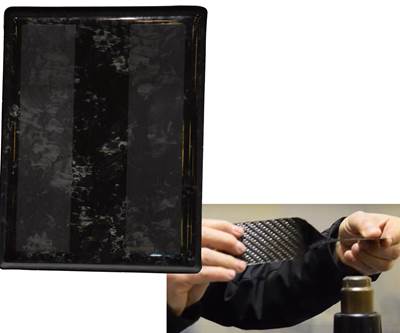

Read MoreRecycled thermoplastic composite rotorcraft access panel takes flight

Designed as part of the TPC-Cycle program, the flight-tested panel demonstrates a lighter, cost-effective, sustainable thermoplastic composite application.

Read MoreLeonardo and CETMA: disrupting composites for lower cost and environmental impact

Italian OEM and tier supplier Leonardo works with CETMA R&D to develop new composite materials, machines and processes, including induction welding for in-situ consolidation of thermoplastic composites.

Read MoreTech Table: Mold release agents

A table of mold release agents collected from data provided by suppliers.

Read MoreSeeking inspiration in a virtual environment

In an increasingly digital world, how far can the virtual environment take us? Only so far, Dale Brosius says. At some point, we have to get real.

Read MoreAutonomous agricultural robot supported by composite components

3D-printed carbon fiber-filled composite components enable a robotic weeding system prototype intended to replace use of chemical herbicides.

Read MoreThe industrialization of thermoplastic epoxy

Fast-processing composites that are strong yet tough, thermoformable, reformable, recyclable and even FST-compliant save cost in aircraft and rail equipment.

Read MoreCorvette, yesterday and today

The Corvette has changed much in 67 years, but its appeal is enduring.

Read MoreCAMX 2020 Preview

Transformed into a virtual event, the latest CAMX 2020 preview describes some of the opportunities that will be available for visitors and exhibitors.

Read MoreAirbag housing prototype puts 3D-printed composites to the test

A feasibility study demonstrated the cost- and time-saving potential of replacing a part’s current materials and processes with additive manufacturing.

Read MoreFRP profiles enable affordable aesthetic solution for unique residential architecture

The FRP profiles, manufactured by Italy-based M.M. S.r.l., allow easy fabrication and construction on-site in less than two days.

Read More