CW Blog

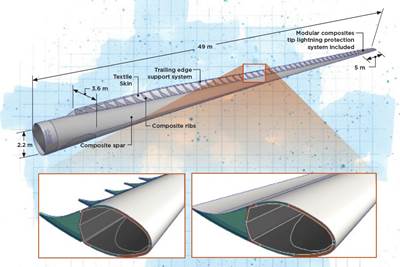

Reimagining wind blade design

Wind turbine blade architecture is so well established that it’s difficult to imagine there might be a better alternative. ACT Blade’s skeleton-based design is a step in that direction.

Read MoreRevisiting the Fundamentals of Light Resin Transfer Molding (LRTM)

Like other closed molding composites processes, Light Resin Transfer Molding (LRTM) offers reduced waste and emissions, efficient materials use and a consistent and repeatable process. But LRTM requires less costly tooling and can still provide excellent cosmetics on both sides of a part in an efficient manufacturing process.

Read MoreLooking for opportunity in a pandemic crisis

How do we determine our next steps in the composites industry amidst a pandemic? Dale Brosius ponders opportunities, risks and changes.

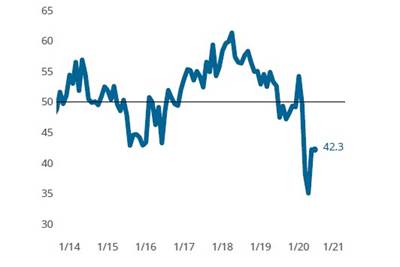

Read MoreRising Composites Index points to slowing contraction in business conditions

Broad-based increase in Index components suggest an industry is slowing its decline.

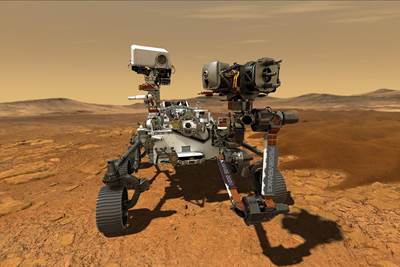

Read MoreComposites launch to Mars

NASA’s recently launched Perseverance rover and Ingenuity helicopter are supported by numerous composite materials and structures.

Read MoreDesigning a carbon fiber SMC brake lever

Germany-based Blackwave GmbH’s bicycle brake lever saves 35% of the weight for a comparable aluminum part.

Read MoreRediscovering the benefits of prepregs in composites manufacturing

Compared to more traditional forms of composites manufacturing, prepregs enable reduced manufacturing costs and enhance production performance.

Read MoreComposites fill the gaps in museum dinosaur skeletons

Ontario-based Research Casting International uses composites to build lightweight, durable dinosaur castings for museums around the world.

Read MoreWebinar presentation: Next-Generation Composites Materials and Processes (July 2020)

CompositesWorld hosted on July 28, 2020, a webinar titled, “Next-Generation Composite Materials and Processes.” If you missed the live webinar, you can watch the recording or download a PDF of the presentation.

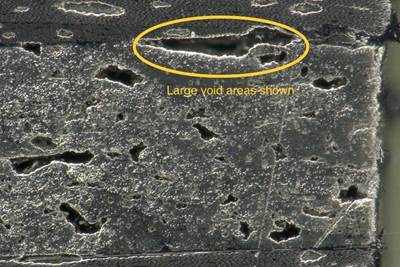

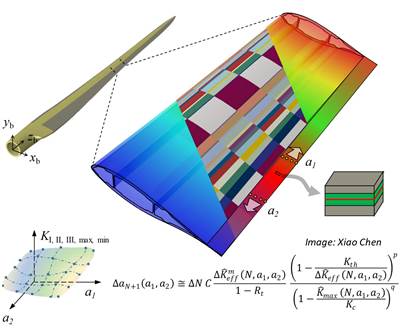

Read MoreFASTIGUE: Empowering digital twins of large-scale composite structures

A 3D finite element technique to resolve the fidelity-versus-speed dilemma of performing fatigue analysis for large composite structures.

Read MoreComposites Index reading remains unchanged from May

June’s readings remain the same as quickening supplier deliveries offset improvement in new orders and production.

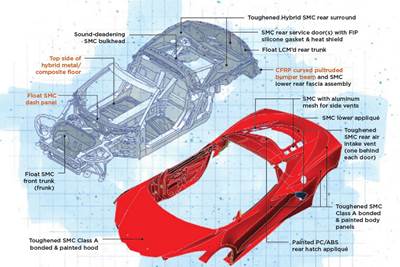

Read MoreComposites-intensive masterwork: 2020 Corvette, Part 2

Innovative composite materials trim mass, costs and noise on the high-volume mid-engine sports car.

Read More