How is tow spread?

ITA characterizes tow spreading processes and parameters as it develops new technology to speed production (100 m/min) and reduce width variation (<1mm).

Read MoreRear wall reboot: One-stop, tow to tape to CFRP part

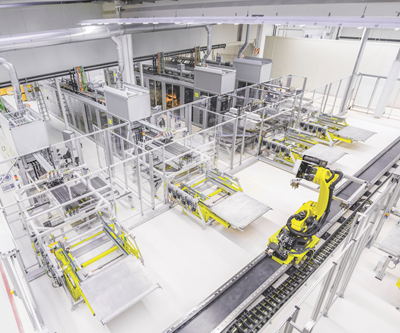

Audi and Voith Composites iterate the CFRP rear wall from R8 sports car to A8 luxury sedan via an automated production line able to output hundreds of parts per day.

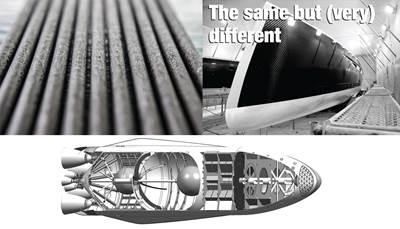

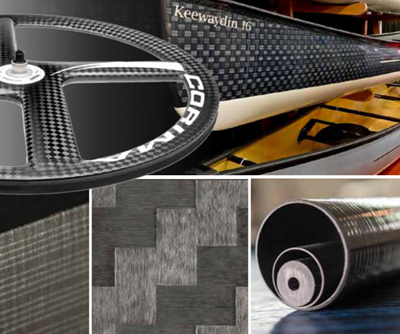

Read MoreSpread tow brings new life to legacy markets

Spread tow and thin ply open new opportunities in composites for golf shafts/driveshafts, boats and spacecraft thanks to improvements in lead time, weight and performance.

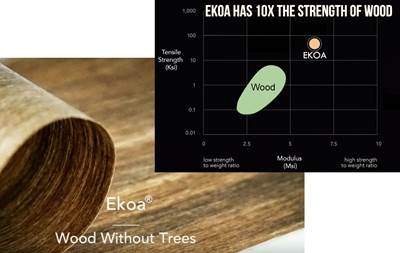

Read MoreEkoa TP, better than wood

Flax fiber/bio-thermoplastic composite provide look and feel of wood but higher properties, targeting $80 billion interiors market and, eventually, a wood replacement for construction.

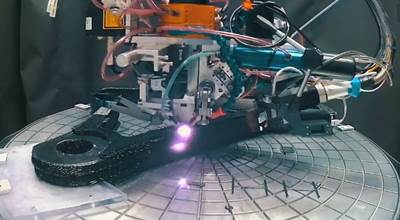

Read MoreArevo in 2018: Industrialized production of continuous fiber 3D-printed parts

With new CEO and $12.5 million in B-series financing, Arevo will have eight direct energy deposition (DED) cells attacking its parts production backlog by year-end.

WatchSGL and Automotive Management Consulting announce cooperation to develop "xFK in 3D" technology

SGL Sigrapreg TowPreg used in patented 3D winding process to produce lightweight, optimized composite structures with efficiency, speed and reduced waste.

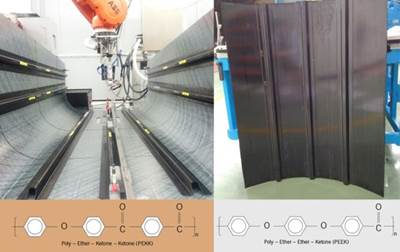

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreThe future of CFRP aerostructures assembly

Metrology, robotics and inline inspection cut cost, reduce shimming and enable future automated production of three vertical tail planes per day.

Read MoreThe spread of spread tow

Advancing from “lighter and thinner” to boosting strength, stiffness, impact resistance and productivity, spread tow unlocks new applications and markets.

Read MoreUpcoming Materials Expo in Charleston, SC

The 5th annual SAMPE Carolinas Materials Expo will be held Thursday, April 26, featuring presentations by Boeing and others, plus new materials and technology developments.

Read MorePEEK or PEKK in future TPC aerostructures?

Which is better for in-situ consolidated thermoplastic composite primary structures? Materials play a part as to whether a one-step or two-step process will prevail.

Read MoreThermoplastic composites: Past the tipping point?

The manufacturing world watched a decade ago as automatically placed thermoset composite tapes replaced aluminum in commercial airframes and made composites a household word in markets around the world. Has the time come for thermoplastic composite tapes to make a similar impact?

Read More