ORNL demonstrates 3-D printing with carbon fiber

Oak Ridge National Laboratory can print carbon fiber reinforced parts from 10 cm in size up to 2.4m in both lab and production settings at its Carbon Fiber Technology Facility.

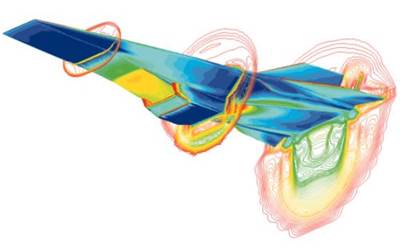

Read MoreThe path toward certification by simulation, Part 3: Simulation governance

Simulation governance is reportedly a prerequisite for certification by simulation, basically enabling V&V and UQ. And yet, it is claimed that the design of most simulation tools used today makes this very difficult, if not impossible. What is this hurdle and how do we overcome it?

Read MoreThe path toward certification by simulation, Part 2: UQ lessons from NNSA

The movement to make certification of composite aircraft structures more affordable is gaining momentum. What lessons can be learned from the National Nuclear Security Administration's 20 years of work toward certification by simulation?

Read MoreThe path toward certification by simulation, Part 1: Verification & validation and uncertainty quantification

The movement to cut time and cost of airframe certification is gaining momentum. What are V&V and UQ and how might they support more reliable composites simulation?

Read MoreFirst A320neo features composite Korean Sharklets

The enhanced performance of Airbus' newest A320 comes not just from the "new engine option" but also from CFRP wingtips produced by Korean Air using an automated manufacturing line.

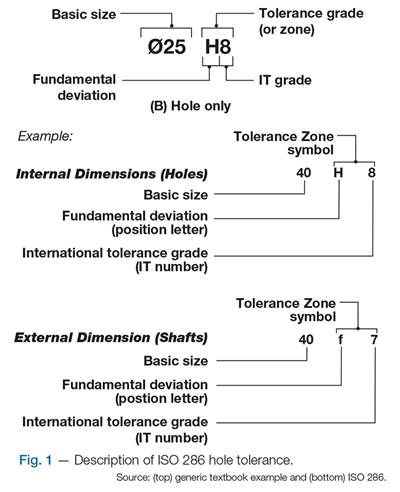

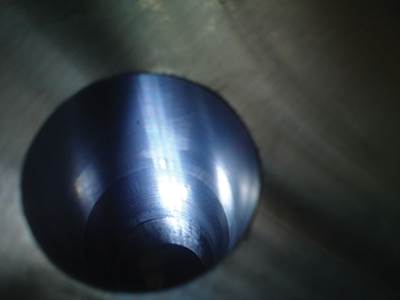

Read MoreHole quality defined

In the aerospace industry, drilled hole quality is defined by ISO 286: System of Limits and Fits, a coordinated system of hole and shaft tolerances that is used in both engineering and production.

Read MoreMachining update: One-shot dry drilling of stacked materials

Tool design innovations tighten tolerances and cut costs for those who drill composite-metal assemblies.

Read MoreA UAV fueled by CNG?

Developed for manned flight, the VX-1 KittyHawk, designed by VX Aerospace (Morgantown, N.C.,) has received more recent attention as a unmanned aerial vehicle (UAV) powered by compressed natural gas.

Read MoreVX Aerospace: Small company, big performance

Innovative design, OOA manufacturing and C-PLY laminate construction produce “big fabricator” aerostructures in fewer steps at low cost.

Read MoreMove over honeycomb, thermoplastic sandwich is commercialized as DYNATECH

PEI foam core/skin sandwich panels claim to save up to 40 percent weight and 30 percent cost in rail and aircraft interiors vs. honeycomb.

Read MoreLicense to speed for composites manufacturing

RocTool pushes composites into new markets with its high-speed induction heating technology for molding.

Read MoreSAMPE Europe highlights: Composites face challenges in next commercial airframes

Airbus Research & Technology presented a sobering outlook and emphasized the need for improved cost, manufacturing and robustness.

Read More